Product Description

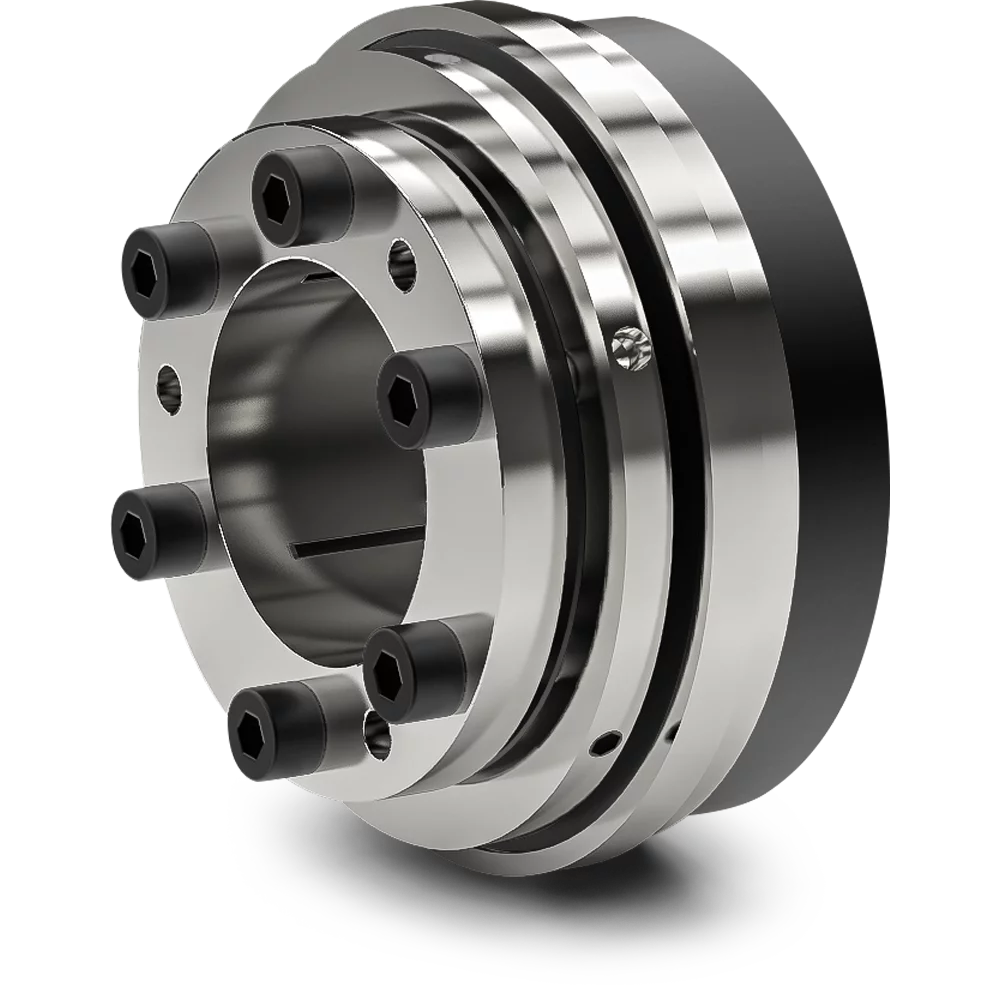

High quality Engine timing belt tensioner Idler for CHINAMFG L 200 PAJERO SPORT IITRITON PLATFORM/CHASSIS 1145A079 1145A571

Product Description

|

Product Name |

High quality Engine timing belt tensioner Idler for CHINAMFG L 200 PAJERO SPORT IITRITON PLATFORM/CHASSIS 1145A079 1145A571 |

| Certification | ISO/TS16949:2009 |

|

OE Number |

1145A079 1145A571 |

| Car Fitment | MITSUBISHI L 200(KB_T,KA_T)) PAJERO SPORT II TRITON PLATFORM/CHASSIS |

|

Quality guarantee |

12 months |

|

Leading time |

30 days |

|

MOQ |

50pcs |

Why Choose Us

1.Reply your enquiry in 24 working hours,any time you can contact me.

2.OEM, buyer design, buyer label services provided.

3.Exclusive and unique solution can be provide to our customer by our welltrained

and professional engineers and staffs.

4.we can provide free sample for your check

5.we have the certification of ISO 9001

6.Special discount and protection of sales area provided to our distributor.

7.timely delivery

8.Good after-sale service

9.Small MOQ is acceptable

Our Service

1.Your inquiry related to our products or prices will be replied in 24 hours.

2.Protection of your sales area, ideas of design and all your private information.

3.Best quality and competitive price.

Packaging & Delivery

1.Packaging Details:Can be customized

2.Delivery Detail:About 3-5 days and based on your requirements.

FAQ

Q1.Are you a Manufacturer or a Trading Company?

A: We are a professional manufacturer specializing in filters for several years.

Factory belong to us,100% industrial corporation,not cooperating partner.It would be our big honor,if you can come to visit us.

Q2.What products can you supply?

A: As a manufacturer, Gpaiplus Company with more than 10 years experience.

We produce a complete range of oil filters, air filters, cabin air filters and fuel filters.If you have your own brand or willing to start one, we would be happy to do OEM for you.

Q3: How is the quality of the filters?How do you guarantee the after-sale service?

A: Strict control before shipment.

If any problems caused by the product itself, we will supply you the new replaced ones ASAP.

Q4. Can I get some samples? How could I pay the sample charge?

A: It depents on the sample costs, but the freight might be bared by our customers.

We accept the sample payment via Western Union,Money Gram or T/T.

Q5. What is the payment terms?

A: Our paymnet terms: 30% deposit before production, 70%balance before shipment.

Q6. How long is your Delivery Time ?

A: If there is stock, the delivery time is about 3-5 working days after getting the payment.

If no stock,30-45 working days according to the order.

/* October 22, 2571 15:47:17 */(()=>{function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the signs that indicate a need for tensioner roller replacement, and how can they be diagnosed?

Identifying the signs that indicate a need for tensioner roller replacement is crucial for maintaining the optimal performance and reliability of a belt drive system. Here’s a detailed explanation of the signs and diagnostic methods for determining when tensioner roller replacement is necessary:

1. Excessive Belt Slack:

If the tensioner roller has worn out or lost its tensioning capability, it may result in excessive belt slack. Excessive belt slack can be observed visually by noticing sagging or drooping of the belt between pulleys. To diagnose this, visually inspect the belt and check for any significant slack or looseness. Excessive belt slack indicates that the tensioner roller is no longer providing adequate tension and should be replaced.

2. Belt Misalignment:

A failing tensioner roller can lead to belt misalignment, causing the belt to deviate from its intended path. Belt misalignment can be diagnosed by observing the belt’s position in relation to the pulleys. Signs of misalignment include the belt running off-center, making contact with adjacent components, or riding too close to the edge of the pulleys. If belt misalignment is detected, it is essential to inspect the tensioner roller for any wear, damage, or misalignment and replace it if necessary.

3. Unusual Noise or Vibration:

A failing tensioner roller can generate unusual noise or vibrations in the belt drive system. This can be caused by worn bearings, misalignment, or other internal damages within the tensioner roller. To diagnose this, carefully listen for any abnormal noises such as grinding, squeaking, or rattling coming from the tensioner roller area while the system is in operation. Additionally, pay attention to any excessive vibrations or shaking of the belt drive system. If unusual noise or vibration is present, it indicates a potential issue with the tensioner roller that may require replacement.

4. Visible Wear or Damage:

Inspecting the tensioner roller for visible wear or damage is an essential diagnostic method. Look for signs of wear, such as cracks, grooves, or uneven surface texture on the roller. Additionally, check for any signs of physical damage, such as dents or deformation. If the tensioner roller shows visible signs of wear or damage, it is an indication that it has reached the end of its service life and should be replaced.

5. Inadequate Tension:

If the tensioner roller fails to provide sufficient tension to the belt, it can lead to belt slippage, reduced power transfer, and decreased overall system performance. Insufficient tension can be diagnosed by observing belt slippage or excessive wear on the belt’s contact surfaces with the pulleys. Check the tension of the belt by applying moderate pressure to it with your finger. If the belt deflects significantly, it indicates inadequate tension provided by the tensioner roller. In such cases, the tensioner roller should be inspected and replaced if necessary.

6. Maintenance Schedule:

Following the manufacturer’s recommended maintenance schedule is an important aspect of diagnosing the need for tensioner roller replacement. Manufacturers often provide guidelines on the expected service life or recommended replacement intervals for tensioner rollers. It is essential to consult the maintenance schedule specific to the belt drive system and adhere to the recommended replacement intervals. This proactive approach helps prevent potential failures or performance issues associated with worn or damaged tensioner rollers.

7. Professional Inspection:

In complex or critical applications, it may be necessary to seek the expertise of a professional technician or engineer to diagnose the need for tensioner roller replacement. Professionals can perform comprehensive inspections using specialized tools and techniques, such as laser alignment or vibration analysis, to assess the condition of the tensioner roller accurately. They can identify any underlying issues or potential risks and provide recommendations for replacement based on the specific requirements of the belt drive system.

In summary, the signs that indicate a need for tensioner roller replacement include excessive belt slack, belt misalignment, unusual noise or vibration, visible wear or damage, inadequate tension, adherence to maintenance schedules, and professional inspections. By regularly inspecting the tensioner roller and promptly addressing any signs of wear or malfunction, operators can ensure the reliable and efficient operation of their belt drive systems.

What factors should be considered when selecting tensioner rollers for different industrial applications?

When selecting tensioner rollers for different industrial applications, several factors need to be taken into consideration. These factors include:

1. Load and Tension Requirements:

The load and tension requirements of the specific industrial application are crucial factors to consider. It is important to determine the maximum load the tensioner roller will experience and the required tension for proper belt operation. This information helps in selecting a tensioner roller that can handle the anticipated loads and provide the necessary tension to prevent belt slippage or excessive wear.

2. Belt Type and Size:

The type and size of the belt being used in the industrial application are important considerations. Different belts have varying characteristics, such as width, thickness, and tooth profile. It is essential to choose a tensioner roller that is compatible with the specific belt type and size to ensure proper fit, alignment, and tension distribution.

3. Operating Speed:

The operating speed of the industrial application is a critical factor when selecting tensioner rollers. High-speed applications generate centrifugal forces that can impact belt tension and introduce vibrations. Tensioner rollers designed for high-speed applications are typically equipped with features to absorb vibrations and maintain consistent tension, ensuring reliable power transmission at elevated speeds.

4. Environmental Conditions:

The environmental conditions in which the tensioner roller will operate should be considered. Factors such as temperature extremes, humidity, dust, dirt, chemicals, and exposure to moisture or corrosive substances can affect the performance and durability of the tensioner roller. Selecting a tensioner roller with appropriate materials and protective coatings ensures its reliability and longevity in the specific environmental conditions.

5. Alignment and Adjustment Mechanism:

The alignment and adjustment mechanism of the tensioner roller play a crucial role in maintaining proper belt tension. Consider the ease of installation, adjustment, and alignment when selecting a tensioner roller. Look for features such as adjustable mounting positions, tension adjustment mechanisms, and reliable locking mechanisms that facilitate easy and precise tension adjustment and alignment of the belt.

6. Maintenance and Serviceability:

The maintenance and serviceability aspects of the tensioner roller should be taken into account. Evaluate the accessibility of the tensioner roller for inspection, lubrication, and maintenance tasks. Choose a tensioner roller that allows for easy replacement of worn or damaged components, minimizing downtime and maintenance costs in the industrial application.

7. Compatibility with the System:

Ensure that the tensioner roller is compatible with the overall belt drive system and other components in the industrial application. Consider factors such as the mounting arrangement, space constraints, and integration with other system elements. Compatibility ensures proper fit, functionality, and overall system performance.

8. Industry Standards and Regulations:

Complying with industry standards and regulations is essential when selecting tensioner rollers for industrial applications. Consider any specific requirements or guidelines set by relevant regulatory bodies or industry associations. Adhering to these standards helps ensure safety, reliability, and compliance with applicable regulations.

In summary, when selecting tensioner rollers for different industrial applications, it is important to consider factors such as load and tension requirements, belt type and size, operating speed, environmental conditions, alignment and adjustment mechanism, maintenance and serviceability, compatibility with the system, and adherence to industry standards and regulations. Considering these factors ensures the appropriate selection of tensioner rollers that will effectively support the belt drive system and optimize the performance and reliability of the industrial application.

How do tensioner rollers differ from other components in a vehicle’s belt drive system?

Tensioner rollers in a vehicle’s belt drive system have distinct characteristics that set them apart from other components. Here’s a detailed explanation of how tensioner rollers differ from other components in a vehicle’s belt drive system:

1. Function:

Tensioner rollers are specifically designed to maintain proper tension in belts within the vehicle’s belt drive system. Their primary function is to apply the necessary force to keep the belts properly tensioned, ensuring efficient power transmission and preventing slippage. Other components in the belt drive system, such as pulleys or idler pulleys, have different functions like redirecting the belt’s path or guiding it around various engine accessories.

2. Design:

Tensioner rollers, also known as belt tensioners or idler pulleys, typically consist of a pulley-like structure mounted on a spring-loaded arm or bracket. They have a smooth or grooved surface that comes into contact with the belt. The design allows the tensioner roller to rotate freely on bearings or bushings, accommodating the movement of the belt and maintaining the desired tension. In contrast, other components in the belt drive system, such as crankshaft pulleys or accessory pulleys, have different shapes and configurations depending on their specific tasks.

3. Tension Adjustment:

Tensioner rollers are designed to automatically adjust the tension in the belts. They can compensate for belt stretch or wear by adapting their position and maintaining the desired tension level. This self-adjusting feature ensures consistent belt tension throughout the vehicle’s operation. In contrast, other components in the belt drive system usually have a fixed position and do not actively contribute to tension adjustment.

4. Location:

Tensioner rollers are typically positioned at strategic locations within the belt drive system to optimize tensioning. They are often placed in locations where the belt’s tension tends to decrease due to the movement of different engine accessories. This placement allows the tensioner rollers to provide the necessary tension and prevent belt slippage. Other components, such as crankshaft pulleys or accessory pulleys, have specific positions based on their roles in driving the various engine accessories.

5. Maintenance and Replacement:

Tensioner rollers require regular maintenance and inspection to ensure their proper functioning. They may need lubrication, and their condition should be checked for signs of wear, damage, or misalignment. If a tensioner roller is found to be faulty or no longer providing adequate tension, it should be promptly replaced to prevent belt-related issues. Other components in the belt drive system may have their maintenance requirements and replacement intervals based on their specific design and usage.

6. Impact on Belt Performance:

Tensioner rollers have a direct impact on belt performance by maintaining the correct tension. They help prevent belt slippage, ensure optimal power transmission, and contribute to the overall efficiency and reliability of the belt drive system. Other components, although crucial for the system’s operation, may not have the same direct influence on belt tension and performance.

In summary, tensioner rollers differ from other components in a vehicle’s belt drive system in terms of their function, design, tension adjustment capabilities, location, maintenance requirements, and impact on belt performance. Understanding these differences is important for effectively maintaining and optimizing the performance of the belt drive system in a vehicle.

editor by Dream 2024-12-13