Product Description

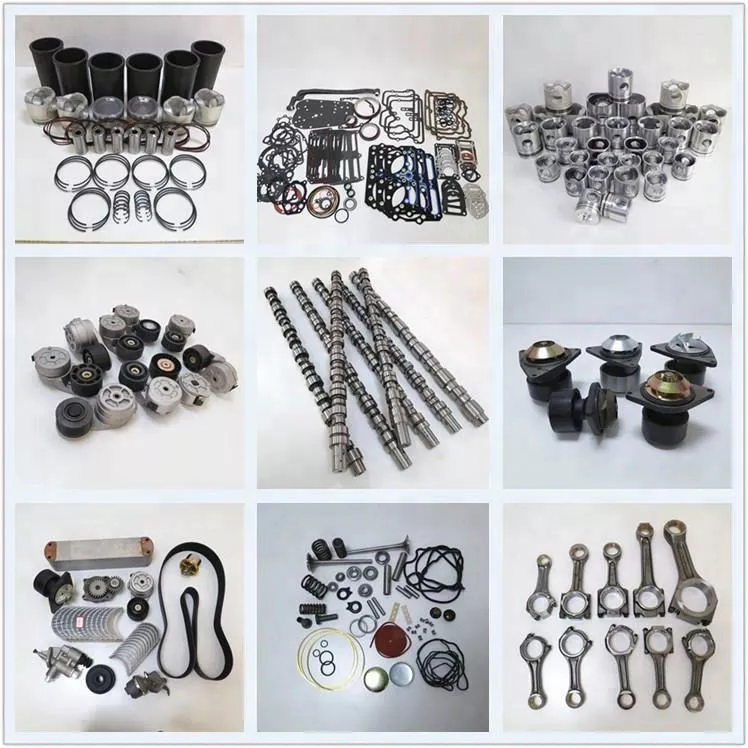

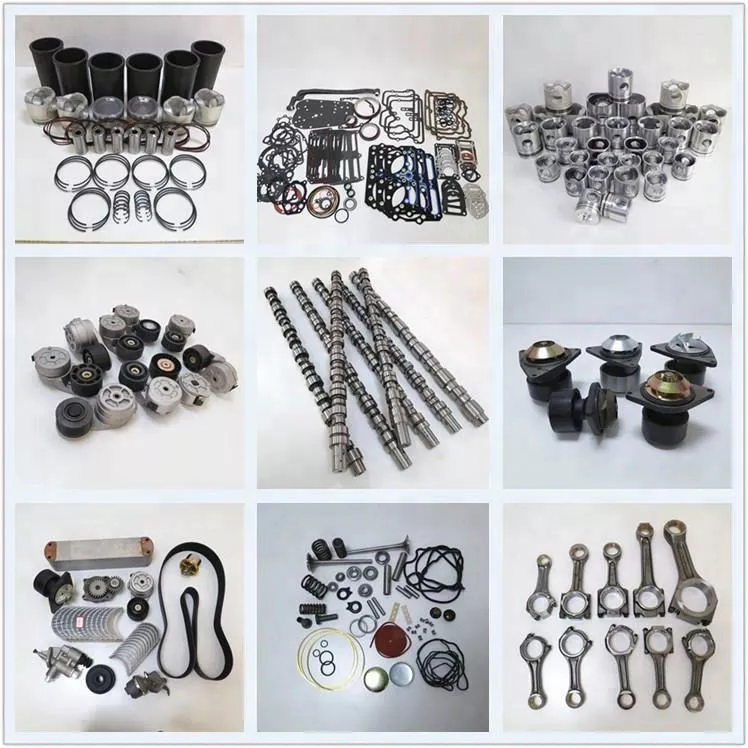

PRODUCT PICTURES:

OUR SERVICES

We can provide manufacturing capabilities and services of regular bearings for you, or customized non-standard bearings as you required.

BEARING:

— Dimensions

— Material

— Tolerance standard

APPEARANCE:

— Logo (Laser Marking)

— Package Design

40+ YEARS EXPERIENCE

CONTINUOUS AND STABLE DELIVERY OF PRODUCTS.

With over 40 years experience of the bearing manufacturing, we know how to make good bearings with less cost consistently and efficiently.

We use advanced CNC turning, grinding, and superfinishing machines to ensure high, stable, and accurate machining. All of your goods, from the most economical category, to the highest rated category, will always be manufactured precisely to the standards you require.

OWN HEAT TREATMENT

CONTROALLABLE COST AND QUALITY.

Heat treatment is 1 of the crucial processes to ensure high performance of bearing materials. Compared with other manufacturers, we can produce higher quality bearings at smaller cost, with a more flexible and controllable production schedule, and in a shorter time.

We have 6 heat treatment production lines.

Bearings are heated uniformly, with small deformation and little/no oxidized decarburization, which can make them have high hardness, high fatigue resistance, good wear resistance, dimensional stability, and excellent mechanical strength.

OUTSTXIHU (WEST LAKE) DIS. QUALITY

LOW NOISE, LOW FRICTION AND LONG LIFE.

All our products are characterized by low noise, low friction and long life. This is due to our attention to the roundness, waviness and surface roughness of bearing raceway.

Our products fully meets the requirements of national and international standards according to the testing result of roughness, roundness, hardness, vibration noise, vibration velocity.

PACKING

PACKAGING THAT HELPS SELL.

1, Inner package

Corrosion and Dust Proof PE plastic film / bag packing + Tube packing, or Wrapping tape for larger bearings.

2, Corrugated Individual Box

Our attractive sales-helpful “3-JOYS” package, or as the design of your package.

3, Outer package

Corrugated carton + Wooden pallet

MODERN WELL-ORGANIZED WAREHOUSE

· Constant temperature (20°C) and humidity (RH 52%) warehouse

· Hundreds of models on hand, short delivery time.

HONOR & SYSTEM CERTIFICATES

EXHIBITION

SAMPLES POLICY

FREE SAMPLES AND SHIPPING

We are happy to send you free samples of our bearings for field testing. All transportation costs will be paid by us.

Please note: Depending on the model and value of samples, this policy may not apply!

Please contact our sales staff for details.

TRANSPORTATION

FASTEST DELIVERY TO CUSTOMERS

CUSTOMERS FEEDBACK

PAYMENT TERMS

To facilitate your payment, we offer a variety of options!

FAQ

1, About the lead time.

This depends on several factors, like Is the production schedule tight? Is there a corresponding model in stock, and is there enough of this model in stock? How many pcs of that model would be ordered?

Simply speaking, based on a 20′ GP container load:

| If the model your Preferred is | Sufficient stock | Lead Time |

| Regular models | YES | Within 7 days |

| Regular models | NO | Within 30 days |

| Non-regular model | NO | About 50 days |

For accurate estimate, please contact with our sale stuff. Thanks.

2, Minimum order quantity.

Even just ONE piece of bearing is ok for us.

3, If you don’t know which model is the right choice…

We would like to give you some advise if you like, according to the real situation and demand of your local market. Our purpose is to help you to get proper and right models for your customers, so that you would make a better sales and income finally.

4, Factory Inspection

We surely would welcome you or your representatives to come to our plants or working offices to take a good look and chat with our hardworking honest employees. Ask our sales stuff and she/he will arrange that for you. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Tensioner Bearing |

|---|---|

| Material: | Chrome Steel / Stainless Steel |

| Tolerance: | P0 P5 P6 |

| Certification: | ISO9001 |

| Clearance: | C0 C3 C2 C1 C5 C4 |

| ABS: | Without ABS |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are there aftermarket upgrades available for tensioner rollers to improve their functionality?

Yes, there are aftermarket upgrades available for tensioner rollers that can improve their functionality and performance. Aftermarket upgrades offer alternatives to the original equipment manufacturer (OEM) tensioner rollers, providing enhanced features, materials, and design. Here’s a detailed explanation of aftermarket upgrades for tensioner rollers:

1. High-Performance Materials:

Aftermarket tensioner rollers often utilize high-performance materials that offer improved durability, heat resistance, and wear characteristics compared to standard OEM rollers. These materials may include advanced polymers, reinforced composites, or specialty alloys. Upgrading to tensioner rollers with high-performance materials can enhance their functionality by increasing their lifespan and performance under demanding operating conditions.

2. Upgraded Bearing Systems:

Bearing systems in tensioner rollers can be upgraded with higher-quality bearings or specialized bearing designs. Improved bearing systems can offer smoother operation, reduced friction, and increased load-bearing capacity. Upgraded bearing systems contribute to improved functionality by reducing noise, vibration, and wear, and enhancing overall performance and reliability.

3. Damping Mechanisms:

Some aftermarket tensioner rollers feature enhanced damping mechanisms to reduce belt noise and vibration. These damping mechanisms can include rubberized coatings, silicone inserts, or advanced damping materials. Upgrading to tensioner rollers with improved damping capabilities can enhance functionality by providing a quieter and smoother operation, improving the overall driving experience.

4. Tension Adjustment Features:

Aftermarket tensioner rollers may offer additional features for tension adjustment. These features can include adjustable tension springs, mechanical or hydraulic tensioners, or built-in tension adjustment mechanisms. Upgraded tension adjustment features allow for fine-tuning of belt tension to meet specific performance requirements, optimizing functionality and performance under varying load and operating conditions.

5. Performance-Enhancing Designs:

Aftermarket tensioner rollers may incorporate performance-enhancing design elements. These designs can include optimized pulley profiles, improved belt contact surfaces, or modified geometries for better belt tracking. Performance-enhancing designs contribute to improved functionality by reducing belt slippage, improving power transfer efficiency, and minimizing wear on the belt and other components.

6. Enhanced Durability:

Aftermarket tensioner rollers may offer enhanced durability features to withstand demanding conditions. These features can include reinforced construction, corrosion-resistant coatings, or additional protection against contaminants. Upgrading to tensioner rollers with enhanced durability can enhance their functionality by reducing the risk of premature failure, extending their lifespan, and improving overall system reliability.

7. Compatibility and Fitment:

Aftermarket tensioner rollers are designed to be compatible with specific vehicle makes and models. They are engineered to match the original specifications and fitment requirements, ensuring proper installation and functionality. Upgrading to aftermarket tensioner rollers that are compatible with the vehicle’s belt system promotes optimal functionality and performance.

8. Manufacturer Reputation and Quality:

When considering aftermarket upgrades for tensioner rollers, it is important to choose reputable manufacturers known for their quality products. Selecting aftermarket tensioner rollers from trusted manufacturers ensures that the upgrades will provide the desired functionality and performance improvements, backed by reliable engineering and manufacturing processes.

In summary, aftermarket upgrades for tensioner rollers offer various enhancements to improve their functionality and performance. These upgrades can include high-performance materials, upgraded bearing systems, damping mechanisms, tension adjustment features, performance-enhancing designs, enhanced durability, and compatibility with specific vehicles. Choosing aftermarket upgrades from reputable manufacturers can provide reliable improvements to the functionality of tensioner rollers, contributing to enhanced belt system performance and overall vehicle drivability.

What role do tensioner rollers play in ensuring proper alignment and tension in belt systems?

Tensioner rollers play a crucial role in ensuring proper alignment and tension in belt systems. They perform several key functions that contribute to the overall performance and reliability of belt-driven systems. Here’s a detailed explanation:

1. Maintaining Proper Belt Tension:

Tensioner rollers help maintain the optimal tension in belts. Proper tension is essential for efficient power transmission and preventing belt slippage. Tensioner rollers exert a controlled amount of pressure on the belt, ensuring it remains tensioned within the desired range. By maintaining proper belt tension, tensioner rollers help prevent power loss, slippage, and premature wear of the belt.

2. Absorbing Belt Vibrations:

Vibrations can occur in belt systems due to imbalances, misalignments, or variations in load. These vibrations can lead to increased wear, noise, and reduced belt life. Tensioner rollers are designed to absorb and dampen vibrations, minimizing their impact on the belt. By reducing vibrations, tensioner rollers help maintain proper alignment and tension, enhancing the performance and longevity of the belt system.

3. Reducing Belt Misalignment:

Proper belt alignment is critical for optimal performance and longevity. Tensioner rollers play a role in maintaining belt alignment by exerting consistent pressure on the belt and guiding it along the intended path. They help prevent lateral movement and ensure that the belt remains centered on the pulleys. By minimizing belt misalignment, tensioner rollers reduce wear, noise, and the risk of premature belt failure.

4. Compensating for Belt Stretch:

Belts can experience stretch over time due to the mechanical stresses they undergo during operation. Belt stretch can result in reduced tension and compromised power transmission. Tensioner rollers are designed to compensate for belt stretch by applying additional tension to maintain the desired level of belt tension. This compensation helps prevent belt slippage, excessive wear, and premature failure, ensuring proper alignment and tension in the belt system.

5. Facilitating Belt Tracking:

Proper belt tracking is essential for smooth operation and longevity of the belt system. Tensioner rollers aid in maintaining belt tracking by exerting controlled pressure and guiding the belt along the intended path. They help prevent the belt from wandering or rubbing against the pulleys or other components. By facilitating accurate belt tracking, tensioner rollers contribute to proper alignment, reduced wear, and extended belt life.

6. Supporting Belt Span:

In longer belt spans or applications with heavy loads, tensioner rollers provide support to the belt. They help prevent sagging and excessive flexing of the belt, which can lead to accelerated wear and reduced belt life. By offering support, tensioner rollers contribute to maintaining proper alignment and tension throughout the belt system.

7. Allowing Tension Adjustment:

Tensioner rollers often incorporate mechanisms that allow for tension adjustment. This feature enables fine-tuning of the belt tension to suit specific operating conditions or accommodate changes in load or temperature. Tension adjustment capability ensures that the belt system can be properly tensioned, optimizing performance, and reducing the risk of wear or slippage.

In summary, tensioner rollers play a vital role in ensuring proper alignment and tension in belt systems. They maintain proper belt tension, absorb vibrations, reduce belt misalignment, compensate for belt stretch, facilitate belt tracking, provide belt support, and allow tension adjustment. By performing these functions, tensioner rollers contribute to the overall efficiency, reliability, and longevity of belt-driven systems.

In what types of vehicles or machinery are tensioner rollers commonly used?

Tensioner rollers are commonly used in a variety of vehicles and machinery where belt drive systems are employed. Here’s a detailed explanation of the types of vehicles and machinery in which tensioner rollers are commonly found:

1. Automobiles:

Tensioner rollers are extensively used in automobiles, including passenger cars, SUVs, and light trucks. They are an integral part of the engine’s accessory drive system, where they help maintain proper tension in the belts that drive components such as the alternator, water pump, power steering pump, and air conditioning compressor. Tensioner rollers contribute to the reliable operation of these accessories and play a crucial role in the overall performance of the vehicle’s engine.

2. Commercial Vehicles:

Tensioner rollers are also commonly utilized in commercial vehicles, such as heavy-duty trucks, buses, and delivery vans. These vehicles often have larger and more complex engine systems that require multiple belts to drive various accessories. Tensioner rollers help ensure proper tension in these belts, allowing for efficient power transmission and reliable operation of the engine accessories.

3. Agricultural Equipment:

In the agricultural sector, tensioner rollers find widespread use in various types of machinery, including tractors, combine harvesters, and other farm equipment. These machines often rely on belt drive systems to power critical components like the water pump, alternator, hydraulic systems, or conveyor belts. Tensioner rollers play a vital role in maintaining optimal belt tension, enabling proper functionality and efficient operation of agricultural machinery.

4. Construction and Heavy Machinery:

Tensioner rollers are employed in construction and heavy machinery, such as excavators, loaders, bulldozers, and cranes. These machines utilize belt drive systems to power auxiliary components like hydraulic pumps, generators, or air compressors. Tensioner rollers help ensure that the belts remain properly tensioned, allowing for reliable power transmission and smooth operation of the machinery in demanding construction or industrial environments.

5. Industrial Equipment:

In various industrial applications, tensioner rollers are used in machinery and equipment such as manufacturing systems, conveyor systems, packaging machines, printing presses, and textile machinery. These systems often rely on belt drive mechanisms to transfer power between different components. Tensioner rollers assist in maintaining the desired tension in the belts, ensuring efficient power transmission and reliable operation of industrial equipment.

6. Recreational Vehicles and Boats:

Tensioner rollers are also found in recreational vehicles (RVs) and boats. RVs may have belt drive systems for powering components like air conditioning units, generators, or water pumps. Tensioner rollers help maintain belt tension in these systems, ensuring reliable operation during camping or travel. In boats, tensioner rollers can be used in propulsion systems or to drive accessories like water pumps or alternators, contributing to the smooth and efficient operation of marine engines.

7. Other Applications:

Additionally, tensioner rollers may be utilized in various other applications where belt drive systems are employed. This can include power tools, industrial pumps, compressors, agricultural machinery attachments, and more. Tensioner rollers are versatile components that find application in diverse machinery and equipment that rely on belt drives.

In summary, tensioner rollers are commonly used in vehicles and machinery such as automobiles, commercial vehicles, agricultural equipment, construction and heavy machinery, industrial equipment, recreational vehicles, boats, and other applications where belt drive systems are utilized. Their presence ensures proper tension in belts, contributing to efficient power transmission, reliable operation, and optimal performance in a wide range of equipment and machinery.

editor by Dream 2024-05-03

China OEM Industrial High Precision Deep Groove Ball Bearing with SGS 6008 6009 6010 6011 6012 6013 6014 6015 6016 6017 with high quality

Product Description

Industrial High Precision Deep Groove Ball Bearing with SGS 6016 6017

Closing the deal on November 30, 2017, Great’s directors expressed excitement over the addition of Great, saying, “This integration bearing company bearing shop into the Great Group means thrust roller bearing taper bearing cross reference we can expand our activities in Switzerland,” adding that “with this take-over, pillow bearing spherical plain bearing block we can bring our wide product range in Automation and Drive Systems directly CZPT the Swiss market, bearing block small bearings metric bearings and strengthen the key aspects of the sector in the country.”Greate’s existing product lines needle thrust bearing manufacturers stainless steel ball bearings will be expanded, adding new products that include IPC-based control systems used in a range of industries, especially those who utilize CNC and motion control tasks.

Deep groove ball bearings can support moderate radial loads and moderate axial loads (parallel to the shaft). They can operate at high speeds. Ball bearings with shields or seals for protection are usually lubricated to last for the operating lifeMiniature & Instrument Series, Stainless Steel – Inch and MetricOpen, Shielded, Shielded and Modified Dimension Bearings: Inch MetricSingle Row Deep Groove6000, 6200 and 6300 Series: Open, Shielded, Sealed – Metric

Main purposes:

Automotive: rear wheel, transmission, electrical equipment components

Electric: General Motors, Household Appliances

Other: instruments, internal combustion engines, construction machinery, railway vehicles, handling machinery, agricultural machinery, all kinds of industrial machiner Product

| Bearing Type | Bore Dia (d) (mm) | Outer Dia (D) (mm) | Width (B) (mm) | Radius (min) (rs) (mm) | Dynamic Load Rating (Cr) (N) | Static Load Rating (Cor) (N) | |

| 6004 | Open | 20 | 42 | 12 | 0.6 | 9400 | 5050 |

| 6004-2RS | Sealed | 20 | 42 | 12 | 0.6 | 9400 | 5050 |

| 6004ZZ | Shielded | 20 | 42 | 12 | 0.6 | 9400 | 5050 |

| 6204 | Open | 20 | 47 | 14 | 1 | 12800 | 6650 |

| 6204-2RS | Sealed | 20 | 47 | 14 | 1 | 12800 | 6650 |

| 6204ZZ | Shielded | 20 | 47 | 14 | 1 | 12800 | 6650 |

| 6304 | Open | 20 | 52 | 15 | 1.1 | 15900 | 7850 |

| 6304-2RS | Sealed | 20 | 52 | 15 | 1.1 | 15900 | 7850 |

| 6304ZZ | Shielded | 20 | 52 | 15 | 1.1 | 15900 | 7850 |

| 6005 | Open | 25 | 47 | 12 | 0.6 | 15710 | 5850 |

| 6005-2RS | Sealed | 25 | 47 | 12 | 0.6 | 15710 | 5850 |

| 6005ZZ | Shielded | 25 | 47 | 12 | 0.6 | 15710 | 5850 |

| 6205 | Open | 25 | 52 | 15 | 1 | 14000 | 7850 |

| 6205-2RS | Sealed | 25 | 52 | 15 | 1 | 14000 | 7850 |

| 6205ZZ | Shielded | 25 | 52 | 15 | 1 | 14000 | 7850 |

| 6305 | Open | 25 | 62 | 17 | 1.1 | 20600 | 11300 |

| 6305-2RS | Sealed | 25 | 62 | 17 | 1.1 | 20600 | 11300 |

| 6305ZZ | Shielded | 25 | 62 | 17 | 1.1 | 20600 | 11300 |

Related Products

Company Information

Great Bearing Co., Ltd. is a professional manufacturer engaged in the research, development, production, sale and service of Cylindrical roller bearing, tapered roller bearing, deep groove ball bearing, Spherical roller bearing etc.

Our factory is located in HangZhou city of the biggest bearing market area in China. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including double-end face grinding machine etc., flaw detector…In addition, we have obtained ISO9001: 2008 certificates. Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as Europe, America, Middle East, Africa and Southeast Asian.

We also welcome OEM and ODM orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements.

Certificates

Our advantages

FAQ:

Q: Are you trading company or manufacturer ?

A: We are factory and trading company. Our factory sell market is in china with our brand GREAT.

Q: How long is your delivery time?

A: We have enough stock for roller bearings and ball bearings. Delivery time within 7 days. 15-25 days for 1 container to OEM brand following your request

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge ,please you pay the cost of freight.

Q: What is your payment term?

A: We accept 30% TT advance ,70% balance against the bill lading copy. Also 100% IRR L/C ok.

Packaging & Shipping

How to Fix a Faulty Drive Belt Tensioner

If you’re experiencing grinding, squeaking, or other unusual sounds from your car, your drive belt tensioner may be the culprit. In this article, we’ll discuss why a failed drive belt tensioner may need to be replaced and how to fix it. Once you have determined that your belt tensioner is faulty, you can use a Wrench to remove it and replace it with a new one. After you replace the belt tensioner, it will no longer be making noises.

Problems with timing belt tensioner

Whenever your engine is making strange noises, it is likely that the timing belt tensioner is causing the problem. A bad timing belt tensioner is a big cause of such sounds, as the timing of the engine is critical. When the belt is moving properly, the camshaft and crankshaft are perfectly synchronized, and the valves work in perfect sync during the intake and exhaust strokes of each cylinder.

Other signs of a worn tensioner include rust bleeding and dripping. Usually, rust will appear at the mounting bolts and “stops” on the tensioner. Other symptoms of a worn timing belt tensioner are noise, resistance, and roughness. If any of these symptoms are present, it’s important to get the car fixed as soon as possible. Troubleshooting problems with timing belt tensioner is an easy process if you know the symptoms.

If your car starts making squeaking or grinding noises when you drive, it’s probably the timing belt tensioner. The timing belt can also cause problems with your engine’s valves. When the timing belt is too loose, the valves cannot fully combust the fuel-air mixture. If this problem is left undiagnosed, it could result in severe engine damage. To solve the problem, you must replace the timing belt tensioner.

The repair of the timing belt tensioner is not a difficult job if you’re experienced and comfortable with DIY car repairs. If you have a good knowledge of car repair, you can try to replace it yourself – but don’t forget that it is a complex repair job that requires a lot of skill. So, it’s best to hire a professional mechanic. And if you don’t have the necessary tools and training, you can always try the DIY method.

Other symptoms of a bad timing belt tensioner include an abnormal chirping noise, misfiring, and check engine light malfunction. If you notice any of these symptoms, you should replace the timing belt tensioner as soon as possible. Often, the belt is wearing out and can’t spin freely. You may have to replace the timing belt tensioner to avoid major damage to your engine. The best way to tell if the timing belt tensioner is failing is to check it regularly.

Cost of a new drive belt tensioner

A new drive belt can be expensive. Replacing 1 is usually a straightforward task that requires little knowledge, but some cars are more difficult than others. Replacing a drive belt by yourself may result in the replacement of parts you do not know. You may also encounter problems that cannot be resolved unless you have a mechanic check all the affected parts. You can save money by taking the car to a mechanic before trying to fix the problem yourself.

A drive belt tensioner should last at least 125,000 miles, but can break sooner. Most car mechanics will replace the tensioner after you notice the belt is slipping. It takes about 15 minutes to an hour to replace 1 of these parts, and you can do it yourself with the proper tools. You can also ask about the replacement of pulleys or sprockets. The price of a new drive belt tensioner depends on the make and model of your car.

The average cost to replace a drive belt tensioner is between $235 and $267. This cost includes labor and parts, but doesn’t include taxes or fees. Some vehicles may need related repairs as well, such as serpentine belts or tensioner housing. For a detailed estimate, use the RepairPal Fair Price Estimator. You can compare labor costs and shop for the best price. There are many options available online, and you can choose the most convenient 1 for your needs.

In addition to replacing the drive belt, you should also check the idler pulleys, which do not drive anything. If they have excessive movement, replace them. A failed drive belt tensioner can cause the belt to slip and affect other components of the car. You may also notice warning lights that indicate a problem with the alternator, water pump, or power steering. You should also check your vehicle’s air conditioning.

Replacing the tensioner pulley can be done yourself for about $50. Depending on the type of pulley and belt, you may need to replace other parts of the engine as well. You can save money by replacing a tensioner pulley yourself if you have the time and skills. It’s easy to replace a new drive belt tensioner if you’re a mechanically inclined individual.

Repair options for a failed drive belt tensioner

A failed drive belt tensioner may have several symptoms. For instance, it can make a grinding or squealing sound, and it may emit a burning smell. The battery light on your car may also stay on. These are all signs that your drive belt has failed. However, these symptoms are not always indicative of the failure of the drive belt tensioner. Listed below are some common problems that can be caused by a failed drive belt tensioner.

To check for a failed drive belt tensioner, turn off the engine and examine the arm. If it doesn’t move, it’s time to replace the drive belt. A manual drive belt tensioner is easy to replace. A hydraulic or bad spring drive belt tensioner, however, will not be able to be fixed. If you can’t find a repair shop in your area, visit 1 of NAPA AutoCare locations, or a NAPA online store. They will be able to diagnose the failure and provide solutions for your car.

A spring tensioner is a type of drive belt tensioner that uses a spring-loaded pulley to apply the proper tension to the drive belt. However, spring tensioners can fail and seize if not properly maintained. A hydraulic tensioner uses hydraulic oil under pressure and can malfunction. In some cases, the tensioner can leak oil or lose its ability to tension the drive belt. It can also be damaged by excessive wear, which will cause the belt to break.

A failed drive belt tensioner can affect your car’s performance and functionality. In addition to making your car squeaky and jerky, a failed drive belt tensioner can cause the serpentine or v-belt to slip and wear out prematurely. Repairing a failed drive belt tensioner can also prevent your car from experiencing the same problems in the future. So, what do you do if you find your drive belt is slipping?

If your drive belt tensioner isn’t the problem, you’ll have to replace it. In some cases, a loose tensioner arm can lead to cracks in the tensioner housing. In the worst case scenario, the damaged tensioner can also lead to an overheated engine. Ultimately, a failed drive belt tensioner can cause your car to experience overheating, weak battery charging, and even a weakened power steering system.

Maintenance requirements for a drive belt tensioner

Drive belt tensioner maintenance begins with proper alignment of the pulleys. Misaligned pulleys or drives can wear a belt out too fast. Misalignment can occur if the component was recently replaced. A set of shims can restore the pulleys to the proper alignment. It is important to regularly check the tensioner to ensure proper function. Also, check the belt for cracks or wear.

Before performing any maintenance work, always turn off the drive to protect the motor. The belt should be in a safe position so that it will not fall on the workers. Lock down any moving parts and ensure the fans do not freewheel. When inspecting the drive belt tensioner, examine the belt guard for wear and debris. If the belt is damaged or has excessive heat, it is necessary to clean it or replace it.

It is important to maintain a proper fit between the belt and the drive belt tensioner. An incorrectly-sized drive belt will be difficult to install and adjust. An incorrect-rib count drive belt will fit, but will not last as long. Likewise, drive belts with too many ribs will not last as long. For these reasons, drive belt tensioners should be replaced when they are over 50,000 miles.

A drive belt tensioner is a pulley that rides on the outside surface of the serpentine belt. Its purpose is to maintain constant pressure on the pulleys that power car components. It is typically mounted on the front of the engine, bolted to the crankshaft, and rests against the serpentine belt. If the drive belt is cracked, it needs to be replaced immediately. If the arm is loose or bent, the bearings in the tensioner are probably worn.

The drive belt tensioner is an important part of the drive system, which is essential for smooth operation of the vehicle. However, it does wear out prematurely and should be replaced at a certain mileage. It should also be inspected for normal wear and tear as a result of road dirt, excessive heat, and oil leaks. However, it is important to remember that drive belts are highly sensitive to excessive heat, road dirt, and oil leaks.

China Custom Stainless Steel Sprocket Large Industrial Transmission Driven Roller Tensioner Aluminum Conveyor Metric Idler Aluminum Motorbike Round Link Ball Bearing with Best Sales

Product Description

Stainless Steel Sprocket Large Industrial Transmission Driven Roller Tensioner Aluminum Conveyor Metric Idler Aluminum Motorbike Round Link Ball Bearing

Manufacturer of Sprocket, Chain sprockets, wheel and sprocket, drive sprocket, sprocket wheel, taper lock

sprocket, gear sprocket, idle sprocket, motorcycle sprocket and stainless steel sprocket, can interchange and replace with martin size sprocket, jt size sprockets, did size chain sprocket and so on.

How to Fix a Faulty Drive Belt Tensioner

If you’re experiencing grinding, squeaking, or other unusual sounds from your car, your drive belt tensioner may be the culprit. In this article, we’ll discuss why a failed drive belt tensioner may need to be replaced and how to fix it. Once you have determined that your belt tensioner is faulty, you can use a Wrench to remove it and replace it with a new one. After you replace the belt tensioner, it will no longer be making noises.

Problems with timing belt tensioner

Whenever your engine is making strange noises, it is likely that the timing belt tensioner is causing the problem. A bad timing belt tensioner is a big cause of such sounds, as the timing of the engine is critical. When the belt is moving properly, the camshaft and crankshaft are perfectly synchronized, and the valves work in perfect sync during the intake and exhaust strokes of each cylinder.

Other signs of a worn tensioner include rust bleeding and dripping. Usually, rust will appear at the mounting bolts and “stops” on the tensioner. Other symptoms of a worn timing belt tensioner are noise, resistance, and roughness. If any of these symptoms are present, it’s important to get the car fixed as soon as possible. Troubleshooting problems with timing belt tensioner is an easy process if you know the symptoms.

If your car starts making squeaking or grinding noises when you drive, it’s probably the timing belt tensioner. The timing belt can also cause problems with your engine’s valves. When the timing belt is too loose, the valves cannot fully combust the fuel-air mixture. If this problem is left undiagnosed, it could result in severe engine damage. To solve the problem, you must replace the timing belt tensioner.

The repair of the timing belt tensioner is not a difficult job if you’re experienced and comfortable with DIY car repairs. If you have a good knowledge of car repair, you can try to replace it yourself – but don’t forget that it is a complex repair job that requires a lot of skill. So, it’s best to hire a professional mechanic. And if you don’t have the necessary tools and training, you can always try the DIY method.

Other symptoms of a bad timing belt tensioner include an abnormal chirping noise, misfiring, and check engine light malfunction. If you notice any of these symptoms, you should replace the timing belt tensioner as soon as possible. Often, the belt is wearing out and can’t spin freely. You may have to replace the timing belt tensioner to avoid major damage to your engine. The best way to tell if the timing belt tensioner is failing is to check it regularly.

Cost of a new drive belt tensioner

A new drive belt can be expensive. Replacing 1 is usually a straightforward task that requires little knowledge, but some cars are more difficult than others. Replacing a drive belt by yourself may result in the replacement of parts you do not know. You may also encounter problems that cannot be resolved unless you have a mechanic check all the affected parts. You can save money by taking the car to a mechanic before trying to fix the problem yourself.

A drive belt tensioner should last at least 125,000 miles, but can break sooner. Most car mechanics will replace the tensioner after you notice the belt is slipping. It takes about 15 minutes to an hour to replace 1 of these parts, and you can do it yourself with the proper tools. You can also ask about the replacement of pulleys or sprockets. The price of a new drive belt tensioner depends on the make and model of your car.

The average cost to replace a drive belt tensioner is between $235 and $267. This cost includes labor and parts, but doesn’t include taxes or fees. Some vehicles may need related repairs as well, such as serpentine belts or tensioner housing. For a detailed estimate, use the RepairPal Fair Price Estimator. You can compare labor costs and shop for the best price. There are many options available online, and you can choose the most convenient 1 for your needs.

In addition to replacing the drive belt, you should also check the idler pulleys, which do not drive anything. If they have excessive movement, replace them. A failed drive belt tensioner can cause the belt to slip and affect other components of the car. You may also notice warning lights that indicate a problem with the alternator, water pump, or power steering. You should also check your vehicle’s air conditioning.

Replacing the tensioner pulley can be done yourself for about $50. Depending on the type of pulley and belt, you may need to replace other parts of the engine as well. You can save money by replacing a tensioner pulley yourself if you have the time and skills. It’s easy to replace a new drive belt tensioner if you’re a mechanically inclined individual.

Repair options for a failed drive belt tensioner

A failed drive belt tensioner may have several symptoms. For instance, it can make a grinding or squealing sound, and it may emit a burning smell. The battery light on your car may also stay on. These are all signs that your drive belt has failed. However, these symptoms are not always indicative of the failure of the drive belt tensioner. Listed below are some common problems that can be caused by a failed drive belt tensioner.

To check for a failed drive belt tensioner, turn off the engine and examine the arm. If it doesn’t move, it’s time to replace the drive belt. A manual drive belt tensioner is easy to replace. A hydraulic or bad spring drive belt tensioner, however, will not be able to be fixed. If you can’t find a repair shop in your area, visit 1 of NAPA AutoCare locations, or a NAPA online store. They will be able to diagnose the failure and provide solutions for your car.

A spring tensioner is a type of drive belt tensioner that uses a spring-loaded pulley to apply the proper tension to the drive belt. However, spring tensioners can fail and seize if not properly maintained. A hydraulic tensioner uses hydraulic oil under pressure and can malfunction. In some cases, the tensioner can leak oil or lose its ability to tension the drive belt. It can also be damaged by excessive wear, which will cause the belt to break.

A failed drive belt tensioner can affect your car’s performance and functionality. In addition to making your car squeaky and jerky, a failed drive belt tensioner can cause the serpentine or v-belt to slip and wear out prematurely. Repairing a failed drive belt tensioner can also prevent your car from experiencing the same problems in the future. So, what do you do if you find your drive belt is slipping?

If your drive belt tensioner isn’t the problem, you’ll have to replace it. In some cases, a loose tensioner arm can lead to cracks in the tensioner housing. In the worst case scenario, the damaged tensioner can also lead to an overheated engine. Ultimately, a failed drive belt tensioner can cause your car to experience overheating, weak battery charging, and even a weakened power steering system.

Maintenance requirements for a drive belt tensioner

Drive belt tensioner maintenance begins with proper alignment of the pulleys. Misaligned pulleys or drives can wear a belt out too fast. Misalignment can occur if the component was recently replaced. A set of shims can restore the pulleys to the proper alignment. It is important to regularly check the tensioner to ensure proper function. Also, check the belt for cracks or wear.

Before performing any maintenance work, always turn off the drive to protect the motor. The belt should be in a safe position so that it will not fall on the workers. Lock down any moving parts and ensure the fans do not freewheel. When inspecting the drive belt tensioner, examine the belt guard for wear and debris. If the belt is damaged or has excessive heat, it is necessary to clean it or replace it.

It is important to maintain a proper fit between the belt and the drive belt tensioner. An incorrectly-sized drive belt will be difficult to install and adjust. An incorrect-rib count drive belt will fit, but will not last as long. Likewise, drive belts with too many ribs will not last as long. For these reasons, drive belt tensioners should be replaced when they are over 50,000 miles.

A drive belt tensioner is a pulley that rides on the outside surface of the serpentine belt. Its purpose is to maintain constant pressure on the pulleys that power car components. It is typically mounted on the front of the engine, bolted to the crankshaft, and rests against the serpentine belt. If the drive belt is cracked, it needs to be replaced immediately. If the arm is loose or bent, the bearings in the tensioner are probably worn.

The drive belt tensioner is an important part of the drive system, which is essential for smooth operation of the vehicle. However, it does wear out prematurely and should be replaced at a certain mileage. It should also be inspected for normal wear and tear as a result of road dirt, excessive heat, and oil leaks. However, it is important to remember that drive belts are highly sensitive to excessive heat, road dirt, and oil leaks.