Product Description

OEM Bearing SL014860 Full Complement Cylindrical Roller Bearing

|

Product Name |

OEM Bearing SL014860 Full Complement Cylindrical Roller Bearing |

|

Brand |

TFN / OEM |

|

Model Number |

SL014860 |

|

Ring Material |

Steel |

|

Cage Material |

Brass,Nylon,Steel |

|

Precision |

P0, P6, P5, or as requested |

|

Vibration |

ZV1, ZV2, ZV3, or as requested |

|

Clearance |

C0,C2,C3, or as requested |

|

Type |

SL series ,N series,NU series,NJ series,Nup series,NF series |

|

Features |

High load carrying capacity ,High stiffness,Accommodate axial displacement ,Low friction ,Long service life,Enhanced operational reliability ,Separable and interchangeable . |

|

Quality standard |

ISO9001:2000/ SGS |

|

Quality Control Process |

1.Assembly |

|

2.Windage test |

|

|

3.Cleaning |

|

|

4.Rotary test |

|

|

5.Greasing and gland |

|

|

6.Noise inspection |

|

|

7.Appearance inspection |

|

|

8.Rust prevention |

|

|

9.Product packaging |

|

|

Application |

cylindrical roller bearing is usually only subject to radial force. Compared with ball bearing of the same size, its radial bearing capacity is increased by 1.5-3 times. It is rigid and shock resistant. It is mainly used for large motor, machine tool spindle, engine front and rear support shaft, train bus axle, diesel engine crankshaft, automobile tractor gearbox, etc. |

Other cylindrical roller bearing models :

| Designation | Principal dimensions | Basic load ratings | Fatigue load limit | Speed ratings | ||||

| dynamic | static | Reference speed | Limiting speed | |||||

| d | D | B | C | C0 | Pu | |||

| mm | kN | kN | r/min | |||||

| NU 202 ECP | 15 | 35 | 11 | 12.5 | 10.2 | 1.22 | 22000 | 26000 |

| NU 202 ECPHA | 15 | 35 | 11 | 12.5 | 10.2 | 1.22 | 22000 | 34000 |

| NJ 202 ECP | 15 | 35 | 11 | 12.5 | 10.2 | 1.22 | 22000 | 26000 |

| NU 203 ECML | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 34000 |

| NJ 203 ECP | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 22000 |

| N 303 ECP | 17 | 47 | 14 | 28.5 | 20.4 | 2.55 | 17000 | 20000 |

| NJ 203 ECPHA | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 30000 |

| NU 303 ECP | 17 | 47 | 14 | 28.5 | 20.4 | 2.55 | 17000 | 20000 |

| NUP 2203 ECP | 17 | 40 | 16 | 27.5 | 21.6 | 2.65 | 20000 | 22000 |

| NU 203 ECP | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 22000 |

| NJ 2203 ECP | 17 | 40 | 16 | 27.5 | 21.6 | 2.65 | 20000 | 22000 |

| NUP 203 ECP | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 22000 |

| NJ 203 ECML | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 34000 |

| N 203 ECP | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 22000 |

| NU 2203 ECP | 17 | 40 | 16 | 27.5 | 21.6 | 2.65 | 20000 | 22000 |

| N 203 ECPH | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 22000 |

| NJ 303 ECP | 17 | 47 | 14 | 28.5 | 20.4 | 2.55 | 17000 | 20000 |

| NU 203 ECPHA | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 30000 |

| NU 2304 ECP | 20 | 52 | 21 | 47.5 | 38 | 4.8 | 15000 | 18000 |

| N 304 ECP | 20 | 52 | 15 | 35.5 | 26 | 3.25 | 15000 | 18000 |

| NU 2204 ECP | 20 | 47 | 18 | 34.5 | 27.5 | 3.45 | 17000 | 19000 |

| NUP 304 ECP | 20 | 52 | 15 | 35.5 | 26 | 3.25 | 15000 | 18000 |

| NUP 204 ECPHA | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 24000 |

| NJ 2304 ECP | 20 | 52 | 21 | 47.5 | 38 | 4.8 | 15000 | 18000 |

| NU 204 ECML | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 30000 |

| NUP 2304 ECP | 20 | 52 | 21 | 47.5 | 38 | 4.8 | 15000 | 18000 |

| NU 204 ECP | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 19000 |

| NJ 204 ECPHA | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 24000 |

| NU 304 ECP | 20 | 52 | 15 | 35.5 | 26 | 3.25 | 15000 | 18000 |

| NJ 2204 ECP | 20 | 47 | 18 | 34.5 | 27.5 | 3.45 | 17000 | 19000 |

| NUP 204 ECP | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 19000 |

| NUP 204 ECML | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 30000 |

| N 204 ECP | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 19000 |

| NJ 204 ECP | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 19000 |

| NJ 304 ECP | 20 | 52 | 15 | 35.5 | 26 | 3.25 | 15000 | 18000 |

| NJ 204 ECML | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 30000 |

Certificate

Packing

FAQ

Q:Why choose SEMRI?

A:1. We are professional,have factory in ZheJiang for many years.

2. We are experienced for 10 years.

3. We can offer a various kind of bearing with high quality:Z1V1,Z2V2,Z3V3 and best price

Q:How is the quality of your products?

A:The same quality, we have lower price.The same price,we have better quality.

Q:Except Full complement Cylindrical roller bearing,what other main bearing do you have?

A:Taper Roller Bearing,Thrust roller bearing,Spherical roller bearing,Deep groove ball bearing,Angular contact ball bearing etc.

Q:Can I get Full complement Cylindrical roller bearing free samples?

A:We will charge a little sample fee for our regular designs or customized ones, These charges will be refunded to you when your mass production order is confirmed.

Q:Can you make the products as our requirement?

A:We have more than 10 year’s OEM experience. We supply products fo more than 300 automobile parts factories.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Double |

| Outer Dimension: | Medium and Large(120-190mm) |

| Material: | Bearing Steel |

| Spherical: | 0 |

| Load Direction: | Radial Bearing |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide insights into the importance of proper tensioner roller alignment?

Proper tensioner roller alignment is of utmost importance in a belt drive system as it directly affects the system’s functionality, performance, and longevity. Here are detailed insights into the importance of proper tensioner roller alignment:

1. Optimal Belt Tension:

Proper tensioner roller alignment ensures optimal belt tension, which is crucial for the efficient operation of the belt drive system. When the tensioner roller is correctly aligned, it applies the appropriate tension to the belt, keeping it properly tensioned and preventing excessive slack or tightness. Optimal belt tension ensures efficient power transfer, minimizes belt slippage, reduces wear on the belt and other components, and maximizes the overall performance of the system.

2. Prevents Belt Misalignment:

Tensioner roller alignment plays a vital role in preventing belt misalignment. Misalignment occurs when the belt deviates from its intended path, causing it to run off-center or make contact with adjacent components. Improper tensioner roller alignment can introduce lateral forces on the belt, leading to misalignment. Belt misalignment can result in reduced power transmission efficiency, increased wear on the belt and pulleys, and the generation of noise and vibrations. Proper tensioner roller alignment helps maintain the belt’s alignment, ensuring smooth operation and minimizing the risk of misalignment-related issues.

3. Reduces Belt Wear and Failure:

Proper tensioner roller alignment helps minimize belt wear and failure. Misalignment can cause the belt to rub against the pulleys or other components, resulting in accelerated wear and damage to the belt. Excessive wear can lead to belt stretching, cracking, or even premature failure. By ensuring proper tensioner roller alignment, the belt remains in its intended position, reducing friction, wear, and the risk of belt failure. This extends the lifespan of the belt and minimizes the need for frequent replacements, resulting in cost savings and improved system reliability.

4. Minimizes Noise and Vibration:

Correct tensioner roller alignment contributes to reduced noise and vibration levels in the belt drive system. Misalignment can cause the belt to oscillate, vibrate, or produce noise as it rubs against the pulleys or other components. These vibrations and noise can be transmitted throughout the system, leading to discomfort, increased wear on components, and a decrease in overall system efficiency. Proper tensioner roller alignment ensures smooth belt operation, minimizing vibrations and noise, and providing a quieter and more comfortable working environment.

5. Improves System Efficiency:

Proper tensioner roller alignment improves the overall efficiency of the belt drive system. Misalignment can result in energy losses due to increased friction, belt slippage, or inefficient power transfer. When the tensioner roller is correctly aligned, it helps maintain optimal belt contact with the pulleys, reducing energy losses and ensuring efficient power transmission. Improved system efficiency leads to reduced energy consumption, increased productivity, and cost savings over the long term.

6. Ensures Reliable Performance:

Tensioner roller alignment is critical for ensuring reliable performance of the belt drive system. Misalignment can lead to unexpected system failures, breakdowns, or unplanned downtime. Proper tensioner roller alignment helps maintain the overall stability and reliability of the system, reducing the risk of sudden failures or disruptions. By ensuring reliable performance, proper tensioner roller alignment contributes to increased productivity, improved operational efficiency, and enhanced system longevity.

7. Facilitates Maintenance and Service:

Proper tensioner roller alignment simplifies maintenance and service tasks. When the tensioner roller is correctly aligned, it is easier to access and adjust, allowing for straightforward tension adjustments or replacement when necessary. Maintenance personnel can quickly identify and address any alignment issues, ensuring that the system remains in optimal working condition. Proper tensioner roller alignment facilitates efficient maintenance practices, reduces downtime during servicing, and enhances the overall serviceability of the belt drive system.

In summary, proper tensioner roller alignment is crucial for the optimal performance, longevity, and reliability of a belt drive system. It ensures optimal belt tension, prevents misalignment, reduces wear on the belt, minimizes noise and vibration, improves system efficiency, and facilitates maintenance and service. By giving due attention to tensioner roller alignment, system operators can maximize the benefits of their belt drive systems and avoid potential issues that can arise from misalignment.

Can you provide examples of products or machinery that use tensioner rollers in their systems?

Yes, tensioner rollers are utilized in various products and machinery where belt drive systems are employed. Here are some examples of products and machinery that use tensioner rollers:

1. Automotive Engines:

In automotive engines, tensioner rollers are commonly used in the accessory belt drive systems. These systems power components such as the alternator, power steering pump, water pump, and air conditioning compressor. Tensioner rollers help maintain proper belt tension, ensuring efficient power transmission and preventing belt slippage or failure.

2. Industrial Machinery:

In industrial machinery, tensioner rollers are employed in numerous applications. They can be found in conveyor systems, where they help maintain belt tension and alignment over long distances. Tensioner rollers are also used in manufacturing equipment, printing presses, and packaging machines to ensure optimal belt operation and power transmission.

3. Agricultural Equipment:

Agricultural machinery, such as tractors, combines, and hay balers, often rely on tensioner rollers in their belt-driven systems. These tensioner rollers help maintain proper tension in belts powering various components, such as harvesting equipment, conveyor systems, and hydraulic systems.

4. Construction Machinery:

Tensioner rollers are incorporated into the belt drive systems of construction machinery, including excavators, loaders, and cranes. They ensure proper tension in belts driving components like hydraulic pumps, generators, and conveyor systems, enabling reliable power transmission in demanding construction environments.

5. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems utilize tensioner rollers in their belt drive systems. Tensioner rollers help maintain the correct tension in belts driving components such as fans, blowers, and compressors, ensuring efficient and reliable operation of HVAC systems in residential, commercial, and industrial settings.

6. Power Tools:

Many power tools, such as drills, saws, and sanders, utilize tensioner rollers in their belt drive mechanisms. Tensioner rollers help maintain proper belt tension, ensuring efficient power transfer and reliable operation of the tools, even under heavy loads or high-speed applications.

7. Fitness Equipment:

In fitness equipment, tensioner rollers are commonly used in treadmills, exercise bikes, and rowing machines. These tensioner rollers ensure the correct tension in belts powering the movement mechanisms, providing smooth and consistent resistance, and enabling users to perform workouts effectively.

8. Material Handling Equipment:

Tensioner rollers are crucial components in material handling equipment, including forklifts, palletizers, and conveyor systems. They help maintain proper belt tension, ensuring reliable power transmission and smooth movement of materials in warehouses, distribution centers, and manufacturing facilities.

9. Marine Applications:

In marine applications, tensioner rollers are utilized in belt drive systems for various components, such as water pumps, alternators, and cooling systems. Tensioner rollers help maintain proper belt tension in marine engines, ensuring reliable power transmission and efficient operation in challenging marine environments.

10. Mining Equipment:

Mining equipment, such as crushers, conveyors, and excavators, often incorporate tensioner rollers into their belt drive systems. These tensioner rollers help maintain tension and alignment in belts, enabling reliable and efficient power transmission in demanding mining operations.

In summary, tensioner rollers are utilized in a wide range of products and machinery that rely on belt drive systems. This includes automotive engines, industrial machinery, agricultural equipment, construction machinery, HVAC systems, power tools, fitness equipment, material handling equipment, marine applications, and mining equipment. Tensioner rollers play a crucial role in maintaining proper belt tension, ensuring reliable power transmission, and optimizing the performance of these systems and equipment.

What is a tensioner roller, and what role does it play in mechanical systems?

A tensioner roller, also known as a belt tensioner or idler pulley, is a component commonly used in mechanical systems to maintain proper tension in belts or chains. It plays a crucial role in ensuring the efficient and reliable operation of various systems that rely on the power transmission provided by belts or chains. Here’s a detailed explanation of what a tensioner roller is and the role it plays in mechanical systems:

1. Definition and Construction:

A tensioner roller is a pulley-like component that is typically mounted on a spring-loaded arm or bracket. It consists of a smooth or grooved surface that comes into contact with the belt or chain. The tensioner roller is designed to rotate freely on bearings or bushings, allowing it to accommodate the movement of the belt or chain and maintain the desired tension.

2. Tension Maintenance:

The primary role of a tensioner roller is to maintain the appropriate tension in belts or chains. Tension is crucial for the proper functioning of power transmission systems. If the tension is too loose, the belt or chain may slip, resulting in a loss of power transfer and potential damage to the system. On the other hand, excessive tension can cause increased wear on the belt or chain, as well as strain on other components. The tensioner roller applies the necessary force to keep the belt or chain properly tensioned, ensuring optimal power transmission efficiency and preventing premature wear or failure.

3. Compensation for Belt or Chain Stretch:

Over time, belts and chains can experience stretching due to normal wear and tear or changes in operating conditions. This stretching can lead to a decrease in tension and affect the performance of the mechanical system. Tensioner rollers are designed to compensate for belt or chain stretch by automatically adjusting their position to maintain the desired tension. The spring-loaded arm or bracket allows the tensioner roller to move and adapt to the changing length of the belt or chain, ensuring consistent tension throughout the system’s operation.

4. Noise and Vibration Dampening:

Tensioner rollers also contribute to reducing noise and vibration in mechanical systems. The smooth rotation of the tensioner roller on its bearings or bushings helps absorb and dampen the vibrations generated during the operation of the belt or chain. This reduces the overall noise level and improves the smoothness of the system’s operation, enhancing user comfort and minimizing potential damage caused by excessive vibrations.

5. Maintenance and Replacement:

Proper maintenance of tensioner rollers is essential to ensure their continued functionality. Regular inspections should be conducted to check for signs of wear, damage, or misalignment. If a tensioner roller is found to be worn, damaged, or no longer providing adequate tension, it should be promptly replaced to prevent further complications and maintain the optimal operation of the mechanical system.

6. Applications:

Tensioner rollers are used in a wide range of mechanical systems that rely on belts or chains for power transmission. They can be found in automotive engines, industrial machinery, HVAC systems, printing equipment, and many other applications. The specific design and size of tensioner rollers may vary depending on the requirements of the system in which they are used.

In summary, a tensioner roller is a crucial component in mechanical systems that rely on belts or chains for power transmission. It ensures the proper tension of the belt or chain, compensates for stretch, reduces noise and vibration, and contributes to the overall efficiency and reliability of the system. Regular maintenance and timely replacement of tensioner rollers are essential to ensure optimal performance and prevent potential issues in mechanical systems.

editor by CX 2024-03-29

China best CZPT Cylindrical Roller Bearing China Tensioner Bearing Manufacturers 22212cak CZPT 22313e1a-M-C3 Spherical Roller Bearing, Self Aligning Roller Bearing near me shop

Product Description

HangZhou CZPT Import and Export Co., Ltd.

Factory Add: 801 -827 -129, Floor 8, Building 6, No. 166 ZHangZhou Middle Road, CHangZhou District, ZheJiang Province (Centralized Office Area), HangZhou, ZheJiang , China

Main Products:

*Deep Groove Ball Bearing

*Self-Aligning Ball Bearing

*Cylindrical Roller Bearings

*Spherical Roller Bearing

*Angular Contact Ball Bearings

*Tapered Roller Bearings

*Thrust Ball Bearing

*Thrust Roller Bearing

*Spherical Bearings

*Thin-Walled Bearings

*Miniature Bearings

*Needle Bearing

*Ceramic Bearing

ZXIHU (WEST LAKE) DIS.AO CYLINDRICAL ROLLER BEARING CHINA TENSIONER BEARING MANUFACTURERS 22212CAK CZPT 22313E1A-M-C3 SPHERICAL ROLLER BEARING, SELF ALIGNING ROLLER BEARING

Product Description

|

Product Name |

Outer Spherical Bearing and Bearing Pedestal |

|

Type |

Spherical / Bearing Pedestal |

|

Applicable Industries |

Farm, machinery repair shop, energy, and mining, agricultural machinery |

|

Brand Name |

ZXIHU (WEST LAKE) DIS.AO BEARING |

|

Inner Diameter Size Range Model |

10mm-240mm |

|

Origin |

ZheJiang , China |

|

Accuracy Grade |

P0 P5 P6 |

|

Product Name |

Outer spherical bearing and bearing pedestal |

|

Material |

Chrome Steel GCr15 / Ductile Iron |

|

Retainer |

Steel |

|

Bearing Pedestal Color |

Dark, Green, Blue |

|

Service |

OEM / ODM customized LOGO |

| Double Row Self-Aligning Roller Bearing | |||

| 22205CA | 22308CA | 23571 | 24571 |

| 22206CA | 22308CAK | 23571 | 24571 |

| 22206CAK | 22309CA | 23026 | 24571 |

| 22207CA | 22309CAK | 23571 | 24026 |

| 22207CAK | 22310CA | 23030 | 24571 |

| 22208CA | 22310CAK | 23032 | 24030 |

| 22208CAK | 22311CA | 23034 | 24032 |

| 22209CA | 22311CAK | 23036 | 24034 |

| 22209CAK | 22312CA | 23038 | 24036 |

| 22210CA | 22312CAK | 23040 | 24038 |

| 22210CAK | 22313CA | 23044 | 24040 |

| 22211CA | 22313CAK | 23048 | 24044 |

| 22211CAK | 22314CA | 23052 | 24048 |

| 22212CA | 22314CAK | 23056 | 24052 |

| 22212CAK | 22315CA | 23218 | 24060 |

| 22213CA | 22315CAK | 23220 | |

| 22213CAK | 22316CA | 23222 | 24120 |

| 22214CA | 22316CAK | 23224 | 24122 |

| 22214CAK | 22317CA | 23226 | 24124 |

| 22215CA | 22317CAK | 23228 | 24126 |

| 22215CAK | 22318CA | 23230 | 24128 |

| 22216CA | 22318CAK | 23232 | 24130 |

| 22216CAK | 22319CA | 23234 | 24132 |

| 22217CA | 22319CAK | 23236 | 24134 |

| 22217CAK | 22320CA | 23238 | 24136 |

| 22218CA | 22320CAK | 23240 | 24138 |

| 22218CAK | 22322CA | 24140 | |

| 22219CA | 22322CAK | 23120 | 24144 |

| 22219CAK | 22324CA | 23122 | |

| 22220CA | 22324CAK | 23122N | |

| 22220CAK | 22326CA | 23124 | |

| 22222CA | 22326CAK | 23124N | |

| 22222CAK | 22328CA | 23126 | |

| 22224CA | 22328CAK | 23128 | |

| 22224CAK | 22330CA | 23128N | |

| 22226CA | 22330CAK | 23130 | |

| 22226CAK | 22332CA | 23132 | |

| 22228CA | 22332CAK | 23134 | |

| 22228CAK | 22334CA | 23136 | |

| 22230CA | 22334CAK | 23138 | |

| 22230CAK | 22336CA | 23140 | |

| 22232CA | 22336CAK | 23144 | |

| 22232CAK | 22338CA | 23148 | |

| 22234CA | 22338CAK | 23152 | |

| 22234CAK | 22340CA | 23172 | |

| 22236CA | 22340CAK | 23180 | |

| 22236CAK | 22344CA | ||

| 22238CA | 22344CAK | ||

| 22238CAK | |||

| 22240CA | |||

| 22240CAK | |||

| 22244CA | |||

| 22244CAK | |||

FAQ

Q1:What is your Before-sales Service?

1>. Offer to bear related consultation about technology and application;

2>.Help customers with bearing choice, clearance configuration, products” life and reliability analysis;

3>. Offer highly cost-effective and complete solution program according to site conditions;

4>. Offer localized program on introduced equipment to save running cost

Q2: What is your After-sales Service?

1>. Offer training about bearing installation and maintenance;

2>.Help customers with trouble diagnosis and failure analysis;

3>. Visit customers regularly and feedback their rational suggestions and requirements to the company.

Q3: How about your company’s strength?

1>.FREE SAMPLES:

contact us by email or trade manager, we will send the free samples according to your request.

2>. World-Class Bearing:

We provide our customers with all types of indigenous roller bearings with world-class quality.

3>.OEM or Non-Stand Bearings:

Any requirement for Nonstandard roller bearings is Easily Fulfilled by us due to its vast knowledge and links in the industry.

4>.Genuine products With Excellent Quality:

The company has always proved the 100% quality products it provides with genuine intent.

5>. After Sales Service and Technical Assistance:

The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

6>.Quick Delivery:

The company provides just-in-time delivery with its streamlined supply chain.

7>.Cost Saving:

We provide long-life, shock-resistant, and high-reliability roller bearings with excellent quality and better performance.

Resulting in increased cost savings.

Q4: What will we do if you are not satisfied with the product?

A: If have any abnormal, Please contact us at the first time, we will immediately process

Q5: How long will you respond to our problems?

A: We will respond within 1 hour. 24 hours to solve your problem

Q6: Is optional lubrication provided?

A: We can offer a wide range of oils and greases for a variety of applications. Please contact our engineer for technical

assistance with any special requirements

Why You Should Get a New Timing Belt

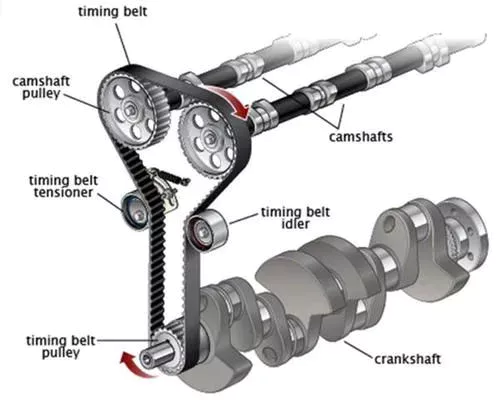

A timing belt is a rubber belt with teeth that transfer rotary motion from the central motor to the drive pulley. It prevents the piston from striking the valves at a critical level. Unfortunately, these belts cost a lot to replace. Here are some reasons why you should consider getting a new one. If you’re not sure whether a new timing belt is necessary, read on. You can also save money by avoiding unnecessary repairs and replacements by choosing an aftermarket timing belt.

Timing belts are rubber belts with hard teeth

While it’s true that timing belts are commonly known as “drive belts,” there are several different types of belts that are used in engines. Despite their commonity, timing belts are made of different materials. The material used to make them is important because it can either negatively impact performance or negatively affect its life span. Whether it’s a car, truck, or motorcycle, timing belts are an essential part of your engine.

Among their many advantages, timing and drive belts are designed to reduce friction, increase speed, and transmit torque more efficiently. In fact, the design of timing belts is similar to that of a cam belt. Both belts work in conjunction with each other to increase the torque and speed of a vehicle. In both types, the teeth of the belt are aligned at the same angle. In a small-scale drive system, this elongation is minimal, but if the load is too high, the teeth of the belt will begin to jump or cog over the pulley’s teeth, causing the noise.

Timing belts are used to synchronize the movement of the crankshaft and camshaft. Timing belts have hard teeth on the inner side of the belt and interlock with the cogwheels on the crankshaft and camshafts. Because of this, they make it easier for the exhaust and intake valves to open and close at the proper time. Timing belts are made of high-10sile rubber, but they may also be polyurethane, welded urethane, or moulded polyurethane.

When a timing belt is worn, it may degrade. The teeth will gradually lose their shape over time and the belt will begin to slip. If the teeth become rounded, the belt may still work, but its timing will be off. Hence, it is vital to replace the timing belt if you notice these signs. If you find any damage, contact a qualified mechanic for repair. If the teeth are worn or damaged, consider replacing the entire belt.

When it comes to a car’s engine, timing is vital. Timing belts connect the internal moving parts of the engine. In addition to timing, they can also power water, oil, and injection pumps. And it’s vital to make sure your timing belt doesn’t get damaged because it will not function properly. So don’t neglect timing belts unless you’re certain they’re damaged.

They transfer rotary motion from the central motor to the drive pulley

A timing belt is a mechanical device that transfers rotary motion from a central motor to a drive pulley through a chain. The belt must be wide enough to accommodate the torque that will be produced by the design. The belt must be wider than the size selected for the drive pulley. In order to determine the correct belt width, the center-to-center distance between the drive pulley and the central motor is measured.

Unlike the elastic belt, which tends to stretch when pressed against a large load, the timing belt does not suffer from this problem. Instead, it exhibits low torsional stiffness, which allows it to transfer rotary motion efficiently. The timing belt also reduces the likelihood of slippage. This is because the cord material is very strong compared to the loads that it must handle.

The most common type of timing belt pulley is made of nylon. The advantage of nylon is that it has a natural lubrication surface and is relatively low-maintenance. It is also durable, malleable, and low-melting point. It is also highly resistant to wear and tear and is suitable for applications that are exposed to high temperatures. However, the belt must be cleaned and maintained on a regular basis.

A Timing belt can be used in a variety of applications. For instance, the timing belt is used in automotive engines. However, the timing belt is also found in stationary power generators, marine engines, and aviation engines. Additionally, it is used in conveyors, winches, treadmills, and washing machines. It also plays a crucial role in the curtain at a theater hall.

The timing belt can be flat, V-shaped, or trapezoidal. The latter is usually made of rubber. The distance between the 2 pulleys is between 5 and 10 meters. The flat belts transmit power through friction between the belt and the pulley. The efficiency of flat belts is approximately 98% and it makes very little noise. However, it must be used in conjunction with the appropriate motor drive. Ultimately, the engineers must choose the best 1 that can deliver the torque that the drive pulley needs to generate.

They prevent pistons from striking the valves on a critical level

In an interference engine, the valves and pistons share the same space in the cylinder, but they move at different rates. While 1 or more of the valves may open into the piston’s travel area, the other is closed and never makes contact with the piston. Timing belts prevent this critical collision from occurring and prevent the piston from damaging the engine. Most timing belts fail at start-up and shutdown. Check the car owner’s manual for recommended replacement intervals.

The timing belt synchronizes the rotation of the crankshaft and camshaft. The timing belt allows the piston to move without striking the valves, allowing the engine to perform its essential functions. The camshaft is used to push fuel and air into the cylinder. The valves close and open as the engine moves forward. When the engine is running, the timing belt prevents the piston from striking the valves on a critical level.

Because of their critical role in the engine, timing belts are often an overlooked component. Without proper timing, an engine will not work properly, and valve damage can be costly. If timing fails, the piston will strike the valves on a critical level, which will damage the engine. Timing belts are a vital automotive component, so make sure yours is in good condition.

A timing belt is a necessary part of your Subaru’s engine. It synchronizes the crankshaft and camshaft to prevent problems with the engine. If a timing belt breaks, the pistons will strike the open valves and cause massive engine damage. Timing belts must be replaced when recommended in your owner’s manual. If it breaks, the engine will shut down.

They cost a lot to replace

Timing belts are expensive to replace, with the average car owner paying $1,200 to have them replaced. Most cars have transverse engines, where the cam cover rests against the driver’s side of the engine. These specialty cars are notoriously difficult to service and require the services of a specialist mechanic. Timing belts are a complex system with a series of idler bearings and tensioner bushes to guide and drive the belt. These components are often replaced at the same time as other routine maintenance work, and they may cost you a bundle.

If you have a car that’s been in the shop for a while, timing belt replacement may be the only option. A timing belt that’s popped isn’t going to make the car run, so you’ll need to get it replaced. If you need the belt replaced, you can use a car service, or you can try to replace the timing belt yourself. It’s a good idea to get several quotes before making the decision to replace the belt.

Depending on the make and model of your car, timing belt replacement costs may range from $250 to more than $1,000. Prices will vary according to vehicle type, labor hours, and the brand of parts and labor. If you don’t have a mechanic handy, you can always use a free online tool like CZPT to get an estimate for timing belt replacement and find a mechanic near you. This will help you save money and avoid the hassle of spending a lot of money on an unnecessary repair.

While timing belts typically last between 60,000 and 100 thousand miles, you may only need to replace them once in your car’s lifetime. Timing belts may seem cheap at first, but if you’re planning on selling your car, you’ll want to avoid the expense of replacing your timing belt. If you don’t, your car’s engine may run poorly and cause your car to use more fuel than it should.

China wholesaler Brass Cage Single Row Nu213em Cylindrical Roller Bearing with Hot selling

Product Description

QUICK OVERVIEW

| Model | Brass Cage Single Row NU213EM Cylindrical roller bearing |

| As your requirement, such as open, z,zz,rz, 2rz,rs, 2rs, and so on. | |

| Vibration | Z1/V1,Z2/V2,Z3/V3 |

| Precision | P6, P0, P5, P4, P2 |

| Internal clearance codes | C0, C2, C3, C4, C5 |

| Snap ring | N, NR |

| Feature | Low voice, High speed, Low friction, long service life |

| Application | Pharmaceutical equipment, medical equipment, textile machinery and accessories, knitting machines, weaving machines, spinning equipment, textile accessories, non-woven fabric machinery, textile equipment, machinery, metal, mold, automotive electronics, electrical, instrumentation, aviation aerospace, plastics and rubber industry, medical and other fields. |

| Package | 1,barreled package+outer carton+pallets 2,single box+outer carton+pallets 3,tube package+middle box+outer carton+pallets 4,According to your’s requirement |

| Details | We have a complete process for production and quality assurance to make sure our products can meet your requirement. 1.Assembly 2.Windage test 3.Cleaning 4.Rotary test 5.Greasing and gland 6.Noise inspection 7.Appearance inspection 8.Rust prevention |

The cylindrical roller bearing is the radial rolling bearing with the cylindrical rollers. The internal structure of the bearing adopts a parallel arrangement of rollers. This type of bearings is the separable bearing. Separate inner ring and outer ring, which are very convenient to install and disassemble, with the advantage of large radial load capacity and low friction coefficient.

The bearing can be divided into single-row, double-row, and multi-rows cylindrical roller bearings according to the number of rows of rolling elements. There are also differences in the design of the position of the ribs.

Picture

Model List (Please contact with us for more models)

| Bearing Number | Boundary dimensions(mm) | Basic load ratings(kN) | Limiting speeds(rpm) | Mass(Kg) | |||||||

| d | D | B | rs min | rs1 min | Cr | Cor | Grease | Oil | (Approx.) | ||

| NU10 Series | NU1005 | 25 | 47 | 12 | 0.6 | 0.3 | 15.1 | 14.1 | 16,000 | 19,000 | 0.092 |

| NU2211E | 55 | 100 | 25 | 1.5 | 1.1 | 97 | 114 | 5,600 | 6,600 | 0.968 | |

| NU2212 | 60 | 110 | 28 | 1.5 | 1.5 | 96 | 116 | 5,800 | 6,800 | 1.06 | |

| NU2212E | 60 | 110 | 28 | 1.5 | 1.5 | 131 | 157 | 5,200 | 6,100 | 1.21 | |

| NU2213 | 65 | 120 | 31 | 1.5 | 1.5 | 120 | 149 | 5,400 | 6,300 | 1.4 | |

| NU2213E | 65 | 120 | 31 | 1.5 | 1.5 | 149 | 181 | 4,800 | 5,600 | 1.6 | |

| NU2214 | 70 | 125 | 31 | 1.5 | 1.5 | 119 | 151 | 5,000 | 5,900 | 1.47 | |

| NU2214E | 70 | 125 | 31 | 1.5 | 1.5 | 156 | 194 | 4,500 | 5,200 | 1.7 | |

| NU2215 | 75 | 130 | 31 | 1.5 | 1.5 | 130 | 162 | 4,700 | 5,500 | 1.55 | |

| NU2215E | 75 | 130 | 31 | 1.5 | 1.5 | 162 | 207 | 4,200 | 4,900 | 1.79 | |

| NU2216 | 80 | 140 | 33 | 2 | 2 | 147 | 186 | 4,400 | 5,100 | 1.93 | |

| NU2216E | 80 | 140 | 33 | 2 | 2 | 186 | 243 | 3,900 | 4,600 | 2.12 | |

| NU2217 | 85 | 150 | 36 | 2 | 2 | 170 | 218 | 4,100 | 4,800 | 2.44 | |

| NU2217E | 85 | 150 | 36 | 2 | 2 | 217 | 279 | 3,700 | 4,300 | 2.68 | |

| NU2218 | 90 | 160 | 40 | 2 | 2 | 197 | 248 | 3,900 | 4,600 | 3.1 | |

| NU2218E | 90 | 160 | 40 | 2 | 2 | 242 | 315 | 3,500 | 4,100 | 3.33 | |

| NU2219 | 95 | 170 | 43 | 2.1 | 2.1 | 230 | 298 | 3,600 | 4,300 | 3.79 | |

| NU2219E | 95 | 170 | 43 | 2.1 | 2.1 | 286 | 370 | 3,300 | 3,800 | 4.14 | |

| NU2220 | 100 | 180 | 46 | 2.1 | 2.1 | 258 | 340 | 3,500 | 4,100 | 4.57 | |

| NU2220E | 100 | 180 | 46 | 2.1 | 2.1 | 335 | 445 | 3,100 | 3,600 | 5.01 | |

| NU2222 | 110 | 200 | 53 | 2.1 | 2.1 | 320 | 415 | 3,100 | 3,700 | 6.56 | |

| NU2222E | 110 | 200 | 53 | 2.1 | 2.1 | 385 | 515 | 2,800 | 3,300 | 7.4 | |

| NU2224 | 120 | 215 | 58 | 2.1 | 2.1 | 350 | 460 | 2,900 | 3,400 | 8.19 | |

| NU2224E | 120 | 215 | 58 | 2.1 | 2.1 | 450 | 620 | 2,600 | 3,000 | 9.18 | |

| NU2226 | 130 | 230 | 64 | 3 | 3 | 380 | 530 | 2,600 | 3,100 | 10.2 | |

| NU2226E | 130 | 230 | 64 | 3 | 3 | 530 | 735 | 2,300 | 2,700 | 11.8 | |

| NU2228 | 140 | 250 | 68 | 3 | 3 | 445 | 635 | 2,400 | 2,800 | 12.9 | |

| NU2228E | 140 | 250 | 68 | 3 | 3 | 575 | 835 | 2,100 | 2,500 | 15.8 | |

| NU222E | 110 | 200 | 38 | 2.1 | 2.1 | 293 | 365 | 3,100 | 3,700 | 4.27 | |

| NU2230 | 150 | 270 | 73 | 3 | 3 | 500 | 710 | 2,200 | 2,600 | 16.3 | |

| NU2230E | 150 | 270 | 73 | 3 | 3 | 660 | 980 | 2,000 | 2,400 | 19.7 | |

A wide range of applications:

• agriculture and forestry equipment

• automotive and industrial gearboxes

• automotive and truck electric components, such as alternators

• electric motors

• fluid machinery

• material handling

• power tools and household appliances

• textile machinery

• two Wheeler.

Our Bearing Advantage:

1.ISO Standard

2.Bearing Small order accepted

3.In Stock bearing

4.OEM bearing service

5.Professional:20 years manufacture bearing

6.Customized bearing, Customer’s bearing drawing or samples accepted

7.Competitive price bearing

8.TT Payment or Western Union or PayPal

Our Company

| Packaging Details | 1 piece in a single box 50 boxes in a carton 20 cartons in a pallet |

| Nearest Port | ZheJiang or HangZhou |

| Lead Time | For stock parts: 1-5 days. If no stock parts: <200 pcs: 15-30 days ≥200 pcs: to be negotiated. |

FAQ

1.How do you make our business long-term and good relationship?

– We keep good quality and competitive price to ensure our customers benefit ;

– We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

2.Do you test all your goods before delivery?

– Yes, we have 100% test before delivery

3.What products does your company supply?

– Auto Bearings (Wheel Bearings, Wheel Hub Bearings, Clutch Bearings, Belt Tensioners and Water Pump Bearings etc. )

-Industrial Bearings (Deep Groove Ball Bearings, Tapered Roller Bearings and Pillow Block Bearings).

Types of V-Belts and Their Properties

A v-belt’s inside length and pitch are determined by measuring along the bottom side. The included angle of a v-belt is measured from its flanks when it is extended. Most v-belt sections are 40 degrees. There are different types of v-belts, and the dimensions of each are standardized by different organizations. This article will introduce the different types of v-belts and their properties.

Notched v-belts reduce bending stress

Notched V-belts reduce bending stress by reducing the axial length of the belt by 2 or more notches. These notches are characterized by different profiles, which differ in the pitch angle and the inside length. ISO and DIN standards are followed by the manufacturers of these belts. Notched v-belts are used on industrial machinery in countries other than the US.

Compared to the standard V-belts, notched ones are designed to resist bending stress better and offer better heat dissipation. They also last longer and run cooler than standard V-belts. Furthermore, they are about 2 percent more energy efficient than their standard counterparts. Therefore, notched V-belts are a viable replacement for standard V-belts.

Notched V-belts are commonly used in industrial applications because of their low price, ease of installation, and availability of many sizes. Another advantage of notched V-belts is that they provide more wedging force and higher load capacity. Notched V-belts have a wider v-groove than flat ones, which makes them more effective for heavy-duty applications.

Notched V-belts also provide better traction. They reduce bending stress, which is beneficial for preventing fatigue and tearing of v-belts. Additionally, v-belts can be installed in an existing equipment to add more performance. And with proper maintenance and installation, notched V-belts will provide trouble-free service for many years to come.

Ribbed v-belts reduce heat dissipation

Various kinds of v-belts are available for varying applications. The more popular types are the fractional horsepower and the double-V. Fractional horsepower v-belts are designed for light-duty applications, such as machine shop equipment and household appliances. The common sectional names are 2L, 3L, 4L, and 5L. The L in each of these belts refers to the top width of the belt, multiplied by 1 eighth inch.

Unlike conventional belts, ribbed v-belts are flexible, making them ideal for use in vibrating loads. They reduce heat dissipation and can be ordered in single or multiple sets to match your application. However, ribbed v-belts should not be mounted on deep-groove sheaves, as this can cause the belt to turn over. If you use deep-groove sheaves, the risk of rupture is very high. Deep-groove sheaves can also cut banded belts. Extremely worn sheaves can also cause the belt to rip.

The 2 types of ribbed v-belts differ in their construction and application. While both types have trapezium cross-sections, they are similar in that they are made of polyurethane or other durable materials. Ribbed v-belts have an additional layer of fabric on the elastomer core for reduced noise and better heat dissipation.

Ribbed v-belts are available in a variety of sizes, including trough v-belts. Their cross-sections are categorized by their top and bottom widths and depths. The included angle of most v-belt sections is approximately 40 degrees. Different types of v-belts have different cross-sections, and these cross-sections are standardized by various organizations.

As the load increases, a ribbed v-belt will wedge into the groove and decrease the amount of friction needed to maintain the correct torque. Flat belts can track off the pulleys due to friction. However, V-belts are more stable and require less width than flat belts. The main advantage of ribbed v-belts is their increased efficiency.

The global-local finite-element model is also used to calculate the maximum and minimum J-integrals during a belt’s running cycle. The data is then used to evaluate the durability of ribbed v-belts in various applications. The numerical models used for the calculations involve a ribbed V-belt with 5 full ribs.

Cogged v-belts increase lateral rigidity to reduce belt whip

Cogged v-belts are designed for maximum performance and durability on even the harshest drive systems. These belts are made from high-modulus polyester cords that resist hardening and stretch and provide superior balance and strength. They also feature raw-edge sidewalls to reduce slip and drive vibration. In addition, they have specially-formulated rubber compounds for oil resistance. CZPT Cog-Belt offers substantial savings in downtime, energy consumption and horsepower.

A double cogged v-belt combines the benefits of cogged and double vee-belts. Its bonded reinforced tie band offers enhanced flexibility and reduces belt whipping in multiple-belt drives. Double cogged v-belt dimensions vary depending on the standards of the manufacturer. Regardless of the type, you’ll want to use a belt that is aligned correctly.

Standard v-belts are also known as wrapped or raw edge v-belts. Wrapped V-belts feature fabric covers above and beneath the cord to increase lateral rigidity and reduce belt whip. Cogged V-belts also have fabric covers to prevent wear on the core and increase the belt’s operating temperature. They’re ideally suited for applications that require high-temperature operation.

Cogged V-belts can significantly decrease energy consumption and improve power transmission capabilities. They also have a bias-cut cover stock that provides axial and lateral stability while preserving the cord integrity. A fiber loaded cogged construction offers optimum flexibility while minimizing heat buildup. It can be installed on any type of drive, including chain conveyors and industrial-grade machines.

The two-layer tie-band permanently bonds multiple belts together. This provides maximum cord support, heavy shock absorption, and stability. The belts are also engineered with patented banding processes that eliminate belt turnover and distribute load evenly across the drive. CZPT Cog-Band Belts minimize belt whip and provide stability. They also minimize belt turnover and rollover in heavy-duty industrial applications.

A classic v-belt is the most common and economical belt. Its nominal dimensions are 1/2″ to 1-11/2″ wide and 16″ to 400 inches long. The width is usually 40 degrees. Different organizations use different cross-sections to classify v-belts. The following table provides a general comparison of the 2 types. The Cogged V-Belt is designed to reduce belt whip by increasing the lateral rigidity of the belt.

Cogged v-belts provide superior environmental resistance

The patented design of the Dayco V-Belt provides maximum power transmission while combining the benefits of a cogged belt and raw-edge construction. The belt’s top cogged design helps increase air flow around it, preventing deterioration and extending its useful life. The belt’s three-ply design features neoprene impregnated fabric for superior durability and a specially-formulated polyester cord for increased strength and stability.

A variety of v-belts are available, with cogged and notched versions presenting unique characteristics. Cogged V-belts are more flexible than uncogged versions and feature ‘X’-shaped grooves for enhanced heat dissipation. Cogged V-belts are interchangeable with conventional v-belts, although their ‘X’ design is most common. Hexagonal v-belts are a popular option for applications where traction is needed.

Another type of Cogged V-belt is designed specifically for outdoor power equipment. This v-belt is brown, with smooth clutching covers. Its aramid cord is very strong and provides superior durability in adverse conditions. Cogged V-belts can withstand severe shock loads and are therefore ideal for outdoor power equipment. Furthermore, they offer superior environmental resistance, minimal stretch, and a long service life.

A Cogged V-belt is composed of tensile cords that are supported by a rubber stock. Different manufacturers use different synthetic rubber stocks for this purpose. These materials help to extend the belt’s operating temperature range and resist premature failure. In addition to tensile cords, the belt’s body is covered with a fabric cover. The fabric is treated to form a chemical bond with the core materials, which allows it to withstand constant bending.

China Standard Cylindrical Roller Bearing for Gear Reducer 65X93.1X55mm with Good quality

Product Description

QUICK OVERVIEW

| Model |

Cylindrical Roller Bearing for Gear Reducer 65X93.1X55mm |

| Greese/Oil | As your requirement, such as open, z,zz,rz, 2rz,rs, 2rs, and so on. |

| Vibration | Z1/V1,Z2/V2,Z3/V3 |

| Precision | P6, P0, P5, P4, P2 |

| Internal clearance codes | C0, C2, C3, C4, C5 |

| Snap ring | N, NR |

| Feature | Low voice, High speed, Low friction, long service life |

| Application | Pharmaceutical equipment, medical equipment, textile machinery and accessories, knitting machines, weaving machines, spinning equipment, textile accessories, non-woven fabric machinery, textile equipment, machinery, metal, mold, automotive electronics, electrical, instrumentation, military, aviation aerospace, plastics and rubber industry, medical and other fields. |

| Package | 1,barreled package+outer carton+pallets 2,single box+outer carton+pallets 3,tube package+middle box+outer carton+pallets 4,According to your’s requirement |

| Details | We have a complete process for production and quality assurance to make sure our products can meet your requirement. 1.Assembly 2.Windage test 3.Cleaning 4.Rotary test 5.Greasing and gland 6.Noise inspection 7.Appearance inspection 8.Rust prevention |

The cylindrical roller bearing is the radial rolling bearing with the cylindrical rollers. The internal structure of the bearing adopts a parallel arrangement of rollers. This type of bearings is the separable bearing. Separate inner ring and outer ring, which are very convenient to install and disassemble, with the advantage of large radial load capacity and low friction coefficient.

The bearing can be divided into single-row, double-row, and multi-rows cylindrical roller bearings according to the number of rows of rolling elements. There are also differences in the design of the position of the ribs.

Picture

Model List (Please contact with us for more models)

| Bearing Number | Boundary dimensions(mm) | Basic load ratings(kN) | Limiting speeds(rpm) | Mass(Kg) | |||||||

| d | D | B | rs min | rs1 min | Cr | Cor | Grease | Oil | (Approx.) | ||

| NU10 Series | NU1005 | 25 | 47 | 12 | 0.6 | 0.3 | 15.1 | 14.1 | 16,000 | 19,000 | 0.092 |

| NU2211E | 55 | 100 | 25 | 1.5 | 1.1 | 97 | 114 | 5,600 | 6,600 | 0.968 | |

| NU2212 | 60 | 110 | 28 | 1.5 | 1.5 | 96 | 116 | 5,800 | 6,800 | 1.06 | |

| NU2212E | 60 | 110 | 28 | 1.5 | 1.5 | 131 | 157 | 5,200 | 6,100 | 1.21 | |

| NU2213 | 65 | 120 | 31 | 1.5 | 1.5 | 120 | 149 | 5,400 | 6,300 | 1.4 | |

| NU2213E | 65 | 120 | 31 | 1.5 | 1.5 | 149 | 181 | 4,800 | 5,600 | 1.6 | |

| NU2214 | 70 | 125 | 31 | 1.5 | 1.5 | 119 | 151 | 5,000 | 5,900 | 1.47 | |

| NU2214E | 70 | 125 | 31 | 1.5 | 1.5 | 156 | 194 | 4,500 | 5,200 | 1.7 | |

| NU2215 | 75 | 130 | 31 | 1.5 | 1.5 | 130 | 162 | 4,700 | 5,500 | 1.55 | |

| NU2215E | 75 | 130 | 31 | 1.5 | 1.5 | 162 | 207 | 4,200 | 4,900 | 1.79 | |

| NU2216 | 80 | 140 | 33 | 2 | 2 | 147 | 186 | 4,400 | 5,100 | 1.93 | |

| NU2216E | 80 | 140 | 33 | 2 | 2 | 186 | 243 | 3,900 | 4,600 | 2.12 | |

| NU2217 | 85 | 150 | 36 | 2 | 2 | 170 | 218 | 4,100 | 4,800 | 2.44 | |

| NU2217E | 85 | 150 | 36 | 2 | 2 | 217 | 279 | 3,700 | 4,300 | 2.68 | |

| NU2218 | 90 | 160 | 40 | 2 | 2 | 197 | 248 | 3,900 | 4,600 | 3.1 | |

| NU2218E | 90 | 160 | 40 | 2 | 2 | 242 | 315 | 3,500 | 4,100 | 3.33 | |

| NU2219 | 95 | 170 | 43 | 2.1 | 2.1 | 230 | 298 | 3,600 | 4,300 | 3.79 | |

| NU2219E | 95 | 170 | 43 | 2.1 | 2.1 | 286 | 370 | 3,300 | 3,800 | 4.14 | |

| NU2220 | 100 | 180 | 46 | 2.1 | 2.1 | 258 | 340 | 3,500 | 4,100 | 4.57 | |

| NU2220E | 100 | 180 | 46 | 2.1 | 2.1 | 335 | 445 | 3,100 | 3,600 | 5.01 | |

| NU2222 | 110 | 200 | 53 | 2.1 | 2.1 | 320 | 415 | 3,100 | 3,700 | 6.56 | |

| NU2222E | 110 | 200 | 53 | 2.1 | 2.1 | 385 | 515 | 2,800 | 3,300 | 7.4 | |

| NU2224 | 120 | 215 | 58 | 2.1 | 2.1 | 350 | 460 | 2,900 | 3,400 | 8.19 | |

| NU2224E | 120 | 215 | 58 | 2.1 | 2.1 | 450 | 620 | 2,600 | 3,000 | 9.18 | |

| NU2226 | 130 | 230 | 64 | 3 | 3 | 380 | 530 | 2,600 | 3,100 | 10.2 | |

| NU2226E | 130 | 230 | 64 | 3 | 3 | 530 | 735 | 2,300 | 2,700 | 11.8 | |

| NU2228 | 140 | 250 | 68 | 3 | 3 | 445 | 635 | 2,400 | 2,800 | 12.9 | |

| NU2228E | 140 | 250 | 68 | 3 | 3 | 575 | 835 | 2,100 | 2,500 | 15.8 | |

| NU222E | 110 | 200 | 38 | 2.1 | 2.1 | 293 | 365 | 3,100 | 3,700 | 4.27 | |

| NU2230 | 150 | 270 | 73 | 3 | 3 | 500 | 710 | 2,200 | 2,600 | 16.3 | |

| NU2230E | 150 | 270 | 73 | 3 | 3 | 660 | 980 | 2,000 | 2,400 | 19.7 | |

A wide range of applications:

• agriculture and forestry equipment

• automotive and industrial gearboxes

• automotive and truck electric components, such as alternators

• electric motors

• fluid machinery

• material handling

• power tools and household appliances

• textile machinery

• two Wheeler.

Our Bearing Advantage:

1.ISO Standard

2.Bearing Small order accepted

3.In Stock bearing

4.OEM bearing service

5.Professional:20 years manufacture bearing

6.Customized bearing, Customer’s bearing drawing or samples accepted

7.Competitive price bearing

8.TT Payment or Western Union or PayPal

Our Company

| Packaging Details | 1 piece in a single box 50 boxes in a carton 20 cartons in a pallet |

| Nearest Port | ZheJiang or HangZhou |

| Lead Time | For stock parts: 1-5 days. If no stock parts: <200 pcs: 15-30 days ≥200 pcs: to be negotiated. |

FAQ

1.How do you make our business long-term and good relationship?

– We keep good quality and competitive price to ensure our customers benefit ;

– We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

2.Do you test all your goods before delivery?

– Yes, we have 100% test before delivery

3.What products does your company supply?

– Auto Bearings (Wheel Bearings, Wheel Hub Bearings, Clutch Bearings, Belt Tensioners and Water Pump Bearings etc. )

-Industrial Bearings (Deep Groove Ball Bearings, Tapered Roller Bearings and Pillow Block Bearings).

Why You Should Get a New Timing Belt

A timing belt is a rubber belt with teeth that transfer rotary motion from the central motor to the drive pulley. It prevents the piston from striking the valves at a critical level. Unfortunately, these belts cost a lot to replace. Here are some reasons why you should consider getting a new one. If you’re not sure whether a new timing belt is necessary, read on. You can also save money by avoiding unnecessary repairs and replacements by choosing an aftermarket timing belt.

Timing belts are rubber belts with hard teeth

While it’s true that timing belts are commonly known as “drive belts,” there are several different types of belts that are used in engines. Despite their commonity, timing belts are made of different materials. The material used to make them is important because it can either negatively impact performance or negatively affect its life span. Whether it’s a car, truck, or motorcycle, timing belts are an essential part of your engine.

Among their many advantages, timing and drive belts are designed to reduce friction, increase speed, and transmit torque more efficiently. In fact, the design of timing belts is similar to that of a cam belt. Both belts work in conjunction with each other to increase the torque and speed of a vehicle. In both types, the teeth of the belt are aligned at the same angle. In a small-scale drive system, this elongation is minimal, but if the load is too high, the teeth of the belt will begin to jump or cog over the pulley’s teeth, causing the noise.

Timing belts are used to synchronize the movement of the crankshaft and camshaft. Timing belts have hard teeth on the inner side of the belt and interlock with the cogwheels on the crankshaft and camshafts. Because of this, they make it easier for the exhaust and intake valves to open and close at the proper time. Timing belts are made of high-10sile rubber, but they may also be polyurethane, welded urethane, or moulded polyurethane.

When a timing belt is worn, it may degrade. The teeth will gradually lose their shape over time and the belt will begin to slip. If the teeth become rounded, the belt may still work, but its timing will be off. Hence, it is vital to replace the timing belt if you notice these signs. If you find any damage, contact a qualified mechanic for repair. If the teeth are worn or damaged, consider replacing the entire belt.

When it comes to a car’s engine, timing is vital. Timing belts connect the internal moving parts of the engine. In addition to timing, they can also power water, oil, and injection pumps. And it’s vital to make sure your timing belt doesn’t get damaged because it will not function properly. So don’t neglect timing belts unless you’re certain they’re damaged.

They transfer rotary motion from the central motor to the drive pulley

A timing belt is a mechanical device that transfers rotary motion from a central motor to a drive pulley through a chain. The belt must be wide enough to accommodate the torque that will be produced by the design. The belt must be wider than the size selected for the drive pulley. In order to determine the correct belt width, the center-to-center distance between the drive pulley and the central motor is measured.

Unlike the elastic belt, which tends to stretch when pressed against a large load, the timing belt does not suffer from this problem. Instead, it exhibits low torsional stiffness, which allows it to transfer rotary motion efficiently. The timing belt also reduces the likelihood of slippage. This is because the cord material is very strong compared to the loads that it must handle.

The most common type of timing belt pulley is made of nylon. The advantage of nylon is that it has a natural lubrication surface and is relatively low-maintenance. It is also durable, malleable, and low-melting point. It is also highly resistant to wear and tear and is suitable for applications that are exposed to high temperatures. However, the belt must be cleaned and maintained on a regular basis.

A Timing belt can be used in a variety of applications. For instance, the timing belt is used in automotive engines. However, the timing belt is also found in stationary power generators, marine engines, and aviation engines. Additionally, it is used in conveyors, winches, treadmills, and washing machines. It also plays a crucial role in the curtain at a theater hall.

The timing belt can be flat, V-shaped, or trapezoidal. The latter is usually made of rubber. The distance between the 2 pulleys is between 5 and 10 meters. The flat belts transmit power through friction between the belt and the pulley. The efficiency of flat belts is approximately 98% and it makes very little noise. However, it must be used in conjunction with the appropriate motor drive. Ultimately, the engineers must choose the best 1 that can deliver the torque that the drive pulley needs to generate.

They prevent pistons from striking the valves on a critical level

In an interference engine, the valves and pistons share the same space in the cylinder, but they move at different rates. While 1 or more of the valves may open into the piston’s travel area, the other is closed and never makes contact with the piston. Timing belts prevent this critical collision from occurring and prevent the piston from damaging the engine. Most timing belts fail at start-up and shutdown. Check the car owner’s manual for recommended replacement intervals.

The timing belt synchronizes the rotation of the crankshaft and camshaft. The timing belt allows the piston to move without striking the valves, allowing the engine to perform its essential functions. The camshaft is used to push fuel and air into the cylinder. The valves close and open as the engine moves forward. When the engine is running, the timing belt prevents the piston from striking the valves on a critical level.

Because of their critical role in the engine, timing belts are often an overlooked component. Without proper timing, an engine will not work properly, and valve damage can be costly. If timing fails, the piston will strike the valves on a critical level, which will damage the engine. Timing belts are a vital automotive component, so make sure yours is in good condition.

A timing belt is a necessary part of your Subaru’s engine. It synchronizes the crankshaft and camshaft to prevent problems with the engine. If a timing belt breaks, the pistons will strike the open valves and cause massive engine damage. Timing belts must be replaced when recommended in your owner’s manual. If it breaks, the engine will shut down.

They cost a lot to replace

Timing belts are expensive to replace, with the average car owner paying $1,200 to have them replaced. Most cars have transverse engines, where the cam cover rests against the driver’s side of the engine. These specialty cars are notoriously difficult to service and require the services of a specialist mechanic. Timing belts are a complex system with a series of idler bearings and tensioner bushes to guide and drive the belt. These components are often replaced at the same time as other routine maintenance work, and they may cost you a bundle.

If you have a car that’s been in the shop for a while, timing belt replacement may be the only option. A timing belt that’s popped isn’t going to make the car run, so you’ll need to get it replaced. If you need the belt replaced, you can use a car service, or you can try to replace the timing belt yourself. It’s a good idea to get several quotes before making the decision to replace the belt.

Depending on the make and model of your car, timing belt replacement costs may range from $250 to more than $1,000. Prices will vary according to vehicle type, labor hours, and the brand of parts and labor. If you don’t have a mechanic handy, you can always use a free online tool like CZPT to get an estimate for timing belt replacement and find a mechanic near you. This will help you save money and avoid the hassle of spending a lot of money on an unnecessary repair.

While timing belts typically last between 60,000 and 100 thousand miles, you may only need to replace them once in your car’s lifetime. Timing belts may seem cheap at first, but if you’re planning on selling your car, you’ll want to avoid the expense of replacing your timing belt. If you don’t, your car’s engine may run poorly and cause your car to use more fuel than it should.

China Custom Si Cylindrical Roller Bearing Nu1021c3 with Best Sales

Product Description

QUICK OVERVIEW

| Model |

SI Cylindrical Roller Bearing Nu1571c3 |

| Greese/Oil | As your requirement, such as open, z,zz,rz, 2rz,rs, 2rs, and so on. |

| Vibration | Z1/V1,Z2/V2,Z3/V3 |

| Precision | P6, P0, P5, P4, P2 |

| Internal clearance codes | C0, C2, C3, C4, C5 |

| Snap ring | N, NR |

| Feature | Low voice, High speed, Low friction, long service life |

| Application | Pharmaceutical equipment, medical equipment, textile machinery and accessories, knitting machines, weaving machines, spinning equipment, textile accessories, non-woven fabric machinery, textile equipment, machinery, metal, mold, automotive electronics, electrical, instrumentation, military, aviation aerospace, plastics and rubber industry, medical and other fields. |

| Package | 1,barreled package+outer carton+pallets 2,single box+outer carton+pallets 3,tube package+middle box+outer carton+pallets 4,According to your’s requirement |

| Details | We have a complete process for production and quality assurance to make sure our products can meet your requirement. 1.Assembly 2.Windage test 3.Cleaning 4.Rotary test 5.Greasing and gland 6.Noise inspection 7.Appearance inspection 8.Rust prevention |

The cylindrical roller bearing is the radial rolling bearing with the cylindrical rollers. The internal structure of the bearing adopts a parallel arrangement of rollers. This type of bearings is the separable bearing. Separate inner ring and outer ring, which are very convenient to install and disassemble, with the advantage of large radial load capacity and low friction coefficient.

The bearing can be divided into single-row, double-row, and multi-rows cylindrical roller bearings according to the number of rows of rolling elements. There are also differences in the design of the position of the ribs.

Picture

Model List (Please contact with us for more models)

| Bearing Number | Boundary dimensions(mm) | Basic load ratings(kN) | Limiting speeds(rpm) | Mass(Kg) | |||||||

| d | D | B | rs min | rs1 min | Cr | Cor | Grease | Oil | (Approx.) | ||

| NU10 Series | NU1005 | 25 | 47 | 12 | 0.6 | 0.3 | 15.1 | 14.1 | 16,000 | 19,000 | 0.092 |

| NU2211E | 55 | 100 | 25 | 1.5 | 1.1 | 97 | 114 | 5,600 | 6,600 | 0.968 | |

| NU2212 | 60 | 110 | 28 | 1.5 | 1.5 | 96 | 116 | 5,800 | 6,800 | 1.06 | |

| NU2212E | 60 | 110 | 28 | 1.5 | 1.5 | 131 | 157 | 5,200 | 6,100 | 1.21 | |

| NU2213 | 65 | 120 | 31 | 1.5 | 1.5 | 120 | 149 | 5,400 | 6,300 | 1.4 | |

| NU2213E | 65 | 120 | 31 | 1.5 | 1.5 | 149 | 181 | 4,800 | 5,600 | 1.6 | |

| NU2214 | 70 | 125 | 31 | 1.5 | 1.5 | 119 | 151 | 5,000 | 5,900 | 1.47 | |

| NU2214E | 70 | 125 | 31 | 1.5 | 1.5 | 156 | 194 | 4,500 | 5,200 | 1.7 | |

| NU2215 | 75 | 130 | 31 | 1.5 | 1.5 | 130 | 162 | 4,700 | 5,500 | 1.55 | |

| NU2215E | 75 | 130 | 31 | 1.5 | 1.5 | 162 | 207 | 4,200 | 4,900 | 1.79 | |

| NU2216 | 80 | 140 | 33 | 2 | 2 | 147 | 186 | 4,400 | 5,100 | 1.93 | |

| NU2216E | 80 | 140 | 33 | 2 | 2 | 186 | 243 | 3,900 | 4,600 | 2.12 | |

| NU2217 | 85 | 150 | 36 | 2 | 2 | 170 | 218 | 4,100 | 4,800 | 2.44 | |

| NU2217E | 85 | 150 | 36 | 2 | 2 | 217 | 279 | 3,700 | 4,300 | 2.68 | |

| NU2218 | 90 | 160 | 40 | 2 | 2 | 197 | 248 | 3,900 | 4,600 | 3.1 | |

| NU2218E | 90 | 160 | 40 | 2 | 2 | 242 | 315 | 3,500 | 4,100 | 3.33 | |

| NU2219 | 95 | 170 | 43 | 2.1 | 2.1 | 230 | 298 | 3,600 | 4,300 | 3.79 | |

| NU2219E | 95 | 170 | 43 | 2.1 | 2.1 | 286 | 370 | 3,300 | 3,800 | 4.14 | |

| NU2220 | 100 | 180 | 46 | 2.1 | 2.1 | 258 | 340 | 3,500 | 4,100 | 4.57 | |

| NU2220E | 100 | 180 | 46 | 2.1 | 2.1 | 335 | 445 | 3,100 | 3,600 | 5.01 | |

| NU2222 | 110 | 200 | 53 | 2.1 | 2.1 | 320 | 415 | 3,100 | 3,700 | 6.56 | |

| NU2222E | 110 | 200 | 53 | 2.1 | 2.1 | 385 | 515 | 2,800 | 3,300 | 7.4 | |

| NU2224 | 120 | 215 | 58 | 2.1 | 2.1 | 350 | 460 | 2,900 | 3,400 | 8.19 | |

| NU2224E | 120 | 215 | 58 | 2.1 | 2.1 | 450 | 620 | 2,600 | 3,000 | 9.18 | |

| NU2226 | 130 | 230 | 64 | 3 | 3 | 380 | 530 | 2,600 | 3,100 | 10.2 | |

| NU2226E | 130 | 230 | 64 | 3 | 3 | 530 | 735 | 2,300 | 2,700 | 11.8 | |

| NU2228 | 140 | 250 | 68 | 3 | 3 | 445 | 635 | 2,400 | 2,800 | 12.9 | |

| NU2228E | 140 | 250 | 68 | 3 | 3 | 575 | 835 | 2,100 | 2,500 | 15.8 | |

| NU222E | 110 | 200 | 38 | 2.1 | 2.1 | 293 | 365 | 3,100 | 3,700 | 4.27 | |

| NU2230 | 150 | 270 | 73 | 3 | 3 | 500 | 710 | 2,200 | 2,600 | 16.3 | |

| NU2230E | 150 | 270 | 73 | 3 | 3 | 660 | 980 | 2,000 | 2,400 | 19.7 | |

A wide range of applications:

• agriculture and forestry equipment

• automotive and industrial gearboxes

• automotive and truck electric components, such as alternators

• electric motors

• fluid machinery

• material handling

• power tools and household appliances

• textile machinery

• two Wheeler.

Our Bearing Advantage:

1.ISO Standard

2.Bearing Small order accepted

3.In Stock bearing

4.OEM bearing service

5.Professional:20 years manufacture bearing

6.Customized bearing, Customer’s bearing drawing or samples accepted

7.Competitive price bearing

8.TT Payment or Western Union or PayPal

Our Company

| Packaging Details | 1 piece in a single box 50 boxes in a carton 20 cartons in a pallet |

| Nearest Port | ZheJiang or HangZhou |

| Lead Time | For stock parts: 1-5 days. If no stock parts: <200 pcs: 15-30 days ≥200 pcs: to be negotiated. |

FAQ

1.How do you make our business long-term and good relationship?

– We keep good quality and competitive price to ensure our customers benefit ;

– We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

2.Do you test all your goods before delivery?

– Yes, we have 100% test before delivery

3.What products does your company supply?

– Auto Bearings (Wheel Bearings, Wheel Hub Bearings, Clutch Bearings, Belt Tensioners and Water Pump Bearings etc. )

-Industrial Bearings (Deep Groove Ball Bearings, Tapered Roller Bearings and Pillow Block Bearings).

What to Look for in a Belt Tensioner

If you notice the power steering, air conditioning, or power steering stops working, chances are that your belt tensioner has been compromised. A compromised belt tensioner can be completely destroyed overnight, or it can last for a long time before it breaks. Either way, you should never drive with a faulty belt tensioner. It’s far better to have it replaced before the engine shuts down completely. In addition, replacing a belt tensioner will prevent other complications, such as power steering or air conditioning, from occurring.

Misaligned idler pulley

If the tensioner arm is not rotating freely or has an abnormal chirping noise, it could be the result of a misaligned idler pulley. If this is the case, replace the idler. If the idler does not move, you may need to adjust the accessory mount points or use a laser alignment tool. The tensioner arm is only 1 part of the tensioner.

A misaligned idler pulley on a belt tensioner is usually the cause of a squeaking noise. If this noise continues even after a replacement of the belt, it’s time to replace the whole belt. A misaligned idler pulley can also be the cause of premature belt wear. If the idler pulley is out of alignment, it could also cause the belt to wear too fast and lead to the premature failure of the timing belt.

The tensioner pulley is made of nylon, steel, or plastic. It may be flat or grooved. Before replacing it, check for any cracks, dents, or debris on the pulley’s surface. Plastic pulleys may have broken sidewalls. If the idler pulley is worn out, you might also notice squealing noises when the vehicle is in motion.

The misalignment of a belt is most pronounced when the span between the 2 pulleys is short. When the span is long, however, diagnosing the problem becomes more complicated. Small degrees of offset may not be visible to the naked eye, but a laser alignment tool can help identify these subtle variations. In order to identify a misaligned idler pulley on a belt tensioner, you must first determine its cause.

When the tensioner’s idler pulleys are out of line, a belt tensioner will not be able to properly adjust the torque that the belt is under. This may result in squealing noises. If this is the case, it is time to call a mechanic. He or she will be able to determine the cause and correct it. If you suspect the problem, your next step is to replace the idler pulley on the belt tensioner.

If the ribbed belt is not properly aligned, you may have a misaligned idler pulley. To fix the misalignment, locate the belt adjustment bolt underneath the hood. You should be careful not to damage the alternator or battery terminal while doing this task. If you do accidentally connect the battery positive to the earth, you might be able to damage the ribbed belt and ruin your vehicle’s timing.

Besides a misaligned idler pulley on the belt tensioner, another problem may be the alternator’s serpentine belt. If your car’s alternator belt is not aligned properly, you could have misaligned the alternator’s pulley or a worn-out bearing. Regardless of the cause of your problem, you should have the belt inspected.

Bad idler pulley

Having a Bad Idler Pulley on a Belt Tensioner? If this sounds familiar, then it’s probably time to change it. Idler pulleys slowly take hits while the engine is running, causing the belt to wrap and bend. Eventually, the belt will slip, and a new idler pulley should be installed to ensure optimal tension. But before you spend a dime on a new one, let’s talk about what to look for.

Symptoms of a Bad Idler Pulley: If the noise persists, there is a problem with the idler pulley or its bearing. These parts wear out over time and may eventually cause a cracked idler pulley or serpentine belt. Not only will the idler pulley create an irritating noise, but it will also damage the belt itself, leading to overheating, stalled engine, and even damage the head gaskets. Thankfully, a Bad Idler Pulley on a Belt Tensioner is easily replaced and will only cost about $40.

Although the Idler Pulley is not the most popular component on a car, it’s a critical part that ensures that the engine runs smoothly. It’s easy to overlook this part, but its failure can make it impossible for your vehicle to operate at its optimal level. Moreover, a Bad Idler Pulley on a Belt Tensioner will cause your engine to malfunction, so it’s essential that you check it at regular intervals.

If you notice a squealing noise while driving, the Idler Pulley is likely the culprit. Because of friction between the engine belt and idler pulley, the engine belt rubs against the pulley, causing it to squeak and make a clicking noise. This squealing noise will continue until the problem is repaired or replaced. It’s time to start addressing the problem before it becomes too late.

If you notice the tensioner pulley moving away from the engine, it’s most likely that the pulley is malfunctioning. A belt that is loose or slack may make it difficult to start the car, or your engine may even overheat. If this occurs, it’s crucial to replace the Idler Pulley as soon as possible, because a Bad Idler Pulley on a Belt Tensioner can seriously damage your vehicle.

The Idler Pulley facilitates the motion of the engine belt. It serves as a smooth rotating point that allows the belt to loop without a barrier. Over time, this part of the system will begin to show signs of wear and tear, and replacement is vital to protect your engine, serpentine belt, and other accessories. An early warning sign of a problem is a squealing sound coming from the engine area.

Broken tensioner arm

The belt tensioner is a piece of machinery that is used to keep the belt tight. If this part breaks, you can easily repair it yourself using a long-handled ratchet, serpentine belt tool, or a socket. To repair the tensioner, simply remove the drive belt from the pulley and rotate it to release tension. Check for roughness, resistance, or binding of the drive belt.

Noises caused by the tensioner are a sign of a damaged component or excessive oscillation. These noises are usually caused by worn internal components or the tensioner’s pivot bushing. In some cases, the vibration damping system or a worn-out alternator pulley could also be to blame. If this is the case, replace the pulley and tensioner together. To check the condition of your belt tensioner, follow these steps.

In addition to worn-out springs, a loose or broken pivot arm could be causing your belt to misalign. A worn-out tensioner pulley bushing will also cause vibrations, noise, and seizing. Lastly, a broken tensioner spring could be preventing the belt from maintaining proper tension. Broken springs are also prone to loss of tension due to heat. Damaged tensioner housing can also affect belt tension.

Once the belt is installed, you need to check the condition of the pulley and the tensioner arm. Make sure that the pulley is moving and that the arm is moving smoothly with the cranking and releasing. If the arm is wobbling, the tensioner is failing. If the pulley wobbles or excessive chattering occurs, the tensioner is failing. It can also be seized or jammed.

If the tensioner arm has broken, replace it. Replacing the tensioner can be a tedious task. Be sure to use a suitable tool to tighten the pulley and tensioner. If you are not sure of how to replace the pulley, try using a serp belt tool. Another good option is to purchase a 3/8 drive ratchet. If you don’t have this tool, you can use a long 3/8 extension and a deep socket.

The belt tensioner assembly can fall off the engine, causing damage to the timing belt. If you are replacing it, you must replace it with a new one, and tighten all of the mounting bolts before reinstalling it. To avoid further damage to the engine, ensure you replace the belt with a new tensioner and a new belt. The tensioner is bolted to the engine’s timing cover, so make sure you carefully tighten the bolts when replacing it.

China manufacturer OEM Bearing SL014860 Full Complement Cylindrical Roller Bearing near me manufacturer

Product Description

OEM Bearing SL014860 Full Complement Cylindrical Roller Bearing

|

Product Name |

OEM Bearing SL014860 Full Complement Cylindrical Roller Bearing |

|

Brand |

TFN / OEM |

|

Model Number |

SL014860 |

|

Ring Material |

Steel |

|

Cage Material |

Brass,Nylon,Steel |

|

Precision |

P0, P6, P5, or as requested |

|

Vibration |

ZV1, ZV2, ZV3, or as requested |

|

Clearance |

C0,C2,C3, or as requested |

|

Type |

SL series ,N series,NU series,NJ series,Nup series,NF series |

|

Features |