Product Description

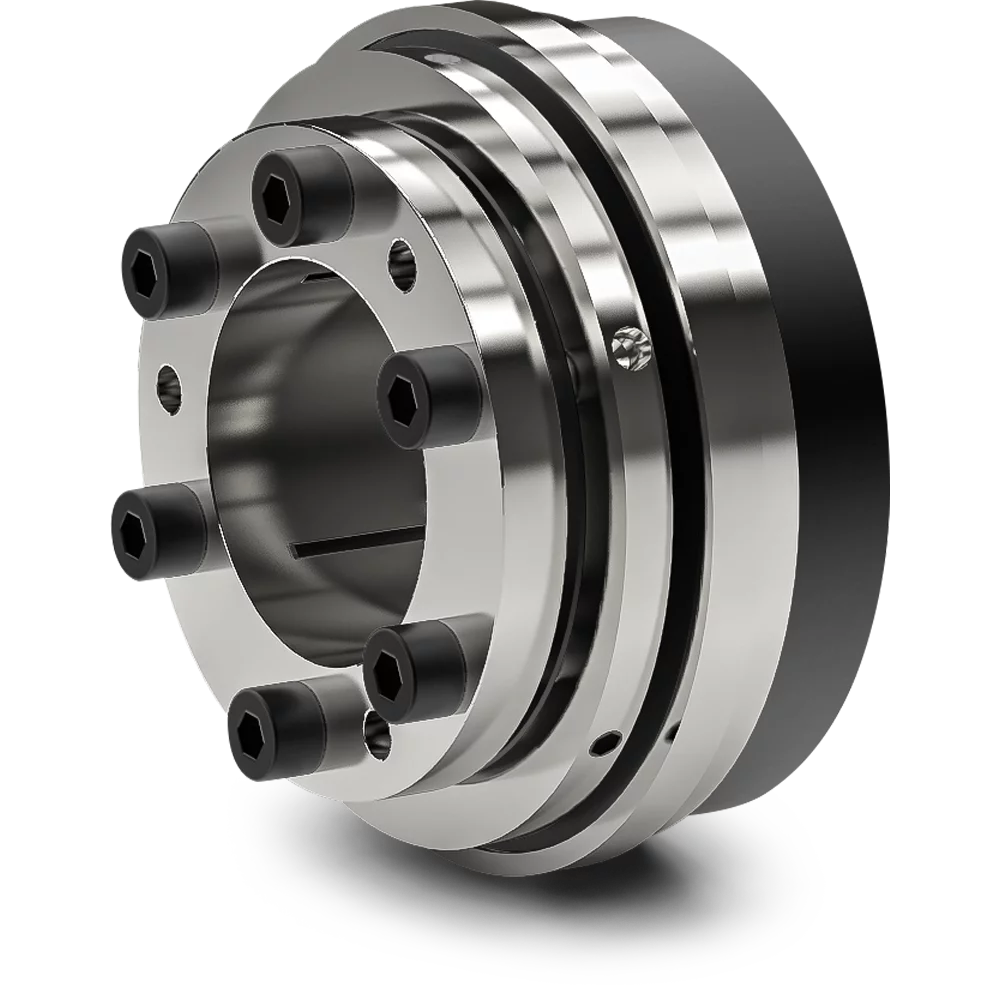

Deep Groove Ball Bearing Auto Parts Accessories Tensioner Bearing with High Speed Rotation

Product Parameters

| Product Name: | Tensioner Bearing |

| Model Number: | 6005LUXZ |

| Outer Diameter(mm) | 52 |

| Height(mm) | 25 |

| Material | Chrome steel |

| Sealed type | OPEN,RZ,2RS,4RS |

| Tolerance | P0,P6,P5,P4,P2 |

| Clearance | C2,C0,C3,C4,C5 |

| Noize level | Z,Z1,Z2,Z3 |

| Application | Automotive Car |

| OEM Service | Accept |

Product Description

Tensioner Bearing:

-The bearings are adopted optimized structure designing so that can attain the traits of high temperature resistant, high speed resistant, long life, high speed rotation,impact resistant,high radial load,etc.

-Sealing structure and seals have the traits of high sealing ability, heat-resistant, abrasiveness and also can prevent the leakage of the grease, as they are helpful for lengthening the bearings’ using life.

Detailed Photos

More Products

Quality Control

Company Profile

ZHangZhouG SHENG YA BEARING TECHNOLOGY CO,LTD.was founded in 1996, covering an area of more than 10,000 square meters, with as sets of more than 50 million yuan, and more than 80 employees, including more than 10 professional and technical personnel with intermediate and senior professional titles. lt specializes in the production of automotive bearings motorcycle bearings, general machine bearings, precision machine tool bearings and home appliance bearings, with an annual production capacity of 10 million sets of small and medium-sized bearings.

Our company undertakes various types of non-standard special-shaped bearings, with a wide variety and fine workmanship. lt is located in Wen.ling, HangZhou City, an important industrial, commercial and tourist city in ZHangZhoug Province, with superior geographical location and convenient transportation.

FAQ

Q1:ls your company factory or Trade Company?

A:We have our own factory, our type is factory +trade.

Q2: Could you accept OEM and customize?

A:Yes, we can customize it for you according to the sample or drawing.

Q3: What is the MOQ of your company?

A:Our MOQ is normally 10pcs, anyway lower MOQ is also acceptable with a little higher cost, as the more you purchase the cheaper cost you could get.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One Year Warranty |

|---|---|

| Warranty: | One Year Warranty |

| Type: | Tensioner Bearing |

| Material: | Chrome Steel |

| Tolerance: | P6 |

| Certification: | ISO9001 |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What is the impact of tensioner rollers on the noise level and vibration in a belt drive system?

Tensioner rollers play a significant role in managing the tension and alignment of belts in a belt drive system, and they can have a notable impact on the noise level and vibration of the system. Here’s a detailed explanation of the impact of tensioner rollers on noise and vibration in a belt drive system:

1. Noise Reduction:

Tensioner rollers help reduce noise in a belt drive system by maintaining proper belt tension and alignment. When the tensioner roller is properly adjusted, it ensures that the belt remains in contact with the pulleys without excessive slack or tension. This helps minimize belt slippage, which is a common source of noise in belt drive systems. Additionally, tensioner rollers with damping mechanisms or optimized designs can further reduce noise by absorbing vibrations and minimizing the transmission of sound waves through the system.

2. Vibration Damping:

Tensioner rollers can also contribute to the damping of vibrations in a belt drive system. Vibrations can occur due to various factors, such as belt misalignment, inconsistent tension, or irregularities in the pulley surfaces. By maintaining proper tension and alignment, tensioner rollers help reduce these vibrations. Additionally, tensioner rollers with damping mechanisms or advanced bearing systems can absorb and dissipate vibrations, further reducing the overall vibration levels in the system.

3. Belt Slap and Flutter Prevention:

Tensioner rollers play a crucial role in preventing belt slap and flutter, which are sources of noise and vibration in belt drive systems. Belt slap occurs when the belt tension is insufficient, causing the belt to oscillate and slap against nearby components. Flutter refers to the rapid vibration or flapping of the belt due to irregular tension or misalignment. Tensioner rollers help maintain proper tension and alignment, preventing belt slap and flutter and consequently reducing the associated noise and vibration.

4. Improved Belt Contact:

Proper tension and alignment provided by tensioner rollers ensure improved belt contact with the pulleys. When the belt is correctly tensioned, it maintains consistent and optimal contact with the pulley surfaces. This results in smoother power transmission and reduced belt slip, which in turn leads to reduced noise and vibration. Tensioner rollers help maintain this optimal belt contact, contributing to quieter and smoother operation of the belt drive system.

5. Reduced Wear and Tear:

By maintaining proper tension and alignment, tensioner rollers help minimize excessive wear and tear on the belt and other components in the drive system. When the belt is properly tensioned, it experiences less stress and friction, reducing the likelihood of noise and vibration-inducing issues such as belt stretching, slipping, or premature wear. By minimizing these factors, tensioner rollers contribute to a quieter and smoother-running belt drive system.

6. System Stability:

Optimal tension and alignment provided by tensioner rollers contribute to the overall stability of the belt drive system. When the belt operates with consistent tension and alignment, it reduces the chances of sudden changes or fluctuations that can lead to noise and vibration. The stability provided by tensioner rollers helps maintain a more controlled and balanced operation, resulting in reduced noise and vibration levels.

7. Maintenance of Performance Over Time:

Tensioner rollers help maintain the performance of the belt drive system over time. As belts naturally wear and stretch over their lifespan, tensioner rollers can compensate for these changes by continuously adjusting the tension. This ensures that the belt remains properly tensioned and aligned, minimizing the risk of noise and vibration issues that can arise from belt deterioration. By maintaining consistent performance, tensioner rollers contribute to a quieter and smoother-running belt drive system throughout its service life.

In summary, tensioner rollers have a significant impact on the noise level and vibration in a belt drive system. They help reduce noise by maintaining proper tension and alignment, absorbing vibrations, preventing belt slap and flutter, and improving belt contact. Tensioner rollers also contribute to smoother operation, reduced wear, increased system stability, and long-term performance maintenance. By ensuring optimal functionality, tensioner rollers help create a quieter and more vibration-free environment in belt drive systems.

Can tensioner rollers be customized for specific industries or machinery configurations?

Yes, tensioner rollers can be customized to suit specific industries or machinery configurations. The ability to customize tensioner rollers allows for optimal performance and compatibility with unique requirements. Here are some aspects to consider:

1. Size and Dimensions:

Tensioner rollers can be customized to meet specific size and dimensional requirements. This includes variations in diameter, width, and overall dimensions to ensure proper fit and alignment within the machinery or system. Custom sizing ensures that the tensioner roller integrates seamlessly with other components and accommodates the available space constraints.

2. Load Capacity:

Industries and machinery configurations can have varying load capacities based on the application’s demands. Customized tensioner rollers can be designed to handle specific load requirements, ensuring they can support the intended loads without compromising performance or longevity. This customization helps prevent premature wear or failure due to excessive loads.

3. Material Selection:

Tensioner rollers can be customized by selecting materials that are best suited for the specific industry or machinery configuration. Different materials offer varying properties such as strength, durability, resistance to heat, chemicals, or abrasion. Customization allows for the selection of materials that can withstand the unique environmental conditions and operational demands of the application.

4. Coatings and Surface Treatments:

Customization of tensioner rollers also includes the application of coatings or surface treatments to enhance their performance and durability. Coatings such as ceramic, rubber, or Teflon can provide increased wear resistance, reduce friction, and improve the lifespan of the tensioner roller. Customized surface treatments can enhance corrosion resistance or provide specific surface properties required for the application.

5. Mounting and Adjustment Mechanisms:

Tensioner rollers can be customized to incorporate specific mounting and adjustment mechanisms based on the machinery or system configuration. This includes options for adjustable mounting positions, tension adjustment features, or quick-release mechanisms for easy installation, maintenance, and tension adjustments. Customized mounting and adjustment mechanisms ensure optimal functionality and ease of use.

6. Special Features and Accessories:

Depending on the industry or machinery requirements, tensioner rollers can be customized with special features and accessories. These may include additional bearings, seals, or guards to enhance protection, improve performance, or meet specific safety standards. Customized tensioner rollers can also incorporate sensors or monitoring systems to enable condition monitoring and predictive maintenance.

7. Compliance with Industry Standards:

Customized tensioner rollers can be designed to comply with specific industry standards, regulations, or certifications. Industries such as automotive, aerospace, or food processing may have stringent requirements that need to be met. Customization ensures that tensioner rollers meet the necessary standards and provide reliable performance within the specified guidelines.

In summary, tensioner rollers can be customized to suit specific industries or machinery configurations. Customization allows for tailoring the size, load capacity, material selection, coatings, mounting mechanisms, special features, and compliance with industry standards. By customizing tensioner rollers, industries can ensure optimal performance, longevity, and compatibility with their unique requirements.

Are there specific applications where tensioner rollers are essential for proper belt operation?

Yes, there are specific applications where tensioner rollers are essential for proper belt operation. Tensioner rollers play a critical role in maintaining optimal belt performance and are particularly important in the following applications:

1. High-Torque Systems:

In applications where high torque is involved, such as heavy machinery or industrial equipment, tensioner rollers are essential for proper belt operation. High torque can exert significant forces on belts, leading to increased tension and potential belt slippage. Tensioner rollers help maintain the correct tension, ensuring secure power transmission and preventing belt failures or damage in these demanding applications.

2. Variable-Speed Drives:

In applications where variable speed is required, such as in automotive engines or industrial machinery, tensioner rollers are crucial for proper belt operation. Variable-speed drives often rely on belt drive systems to adjust the speed of driven components. Tensioner rollers help maintain consistent belt tension, allowing for smooth speed adjustments and reliable operation across different speed ranges.

3. Long Belt Lengths:

In applications that involve long belt lengths, such as conveyor systems or large-scale manufacturing equipment, tensioner rollers are essential. Long belts are prone to stretching and sagging, which can cause misalignment and decreased power transmission efficiency. Tensioner rollers help counteract belt stretch, maintaining the proper tension and alignment over extended distances, ensuring optimal belt operation in these applications.

4. High-Speed Applications:

For high-speed applications, such as in racing vehicles, aircraft engines, or industrial machinery with rapid rotational speeds, tensioner rollers are vital for proper belt operation. High speeds can generate significant centrifugal forces that impact belt tension and introduce vibrations. Tensioner rollers help maintain the necessary tension, absorb vibrations, and prevent belt slippage, ensuring reliable and efficient power transmission at high speeds.

5. Challenging Environments:

In applications exposed to challenging environments, such as off-road vehicles, construction machinery, or marine equipment, tensioner rollers are essential for proper belt operation. Harsh conditions, including dust, dirt, moisture, and temperature variations, can accelerate belt wear and affect performance. Tensioner rollers help maintain optimal belt tension, reducing the risk of belt damage and ensuring reliable operation in these demanding environments.

6. Multi-Belt Systems:

Applications that utilize multi-belt systems, such as heavy-duty trucks, agricultural machinery, or printing presses, require tensioner rollers for proper belt operation. Multi-belt systems often have several belts driving different components or accessories. Tensioner rollers help maintain individual belt tension and overall system balance, preventing belt slippage, ensuring consistent power transmission, and optimizing the performance of the entire system.

7. High-Precision Applications:

In applications that demand high precision, such as CNC machines, robotics, or medical equipment, tensioner rollers are essential for proper belt operation. These applications require accurate and reliable power transmission to ensure precise movements or operations. Tensioner rollers help maintain the correct belt tension, minimizing variations and ensuring consistent performance in high-precision operations.

In summary, tensioner rollers are essential for proper belt operation in various specific applications, including high-torque systems, variable-speed drives, long belt lengths, high-speed applications, challenging environments, multi-belt systems, and high-precision applications. Incorporating tensioner rollers in these applications is crucial for maintaining optimal belt performance, preventing belt failures, and ensuring reliable and efficient operation of the belt drive systems.

editor by CX 2024-04-03

China high quality Auto Parts Bearing Motorcycle Parts Bearing Car Accessories Bearing Auto Spare Part Bearing Spare Parts Bearing Engine Parts Bearing Wheel Bearing Taper Roller

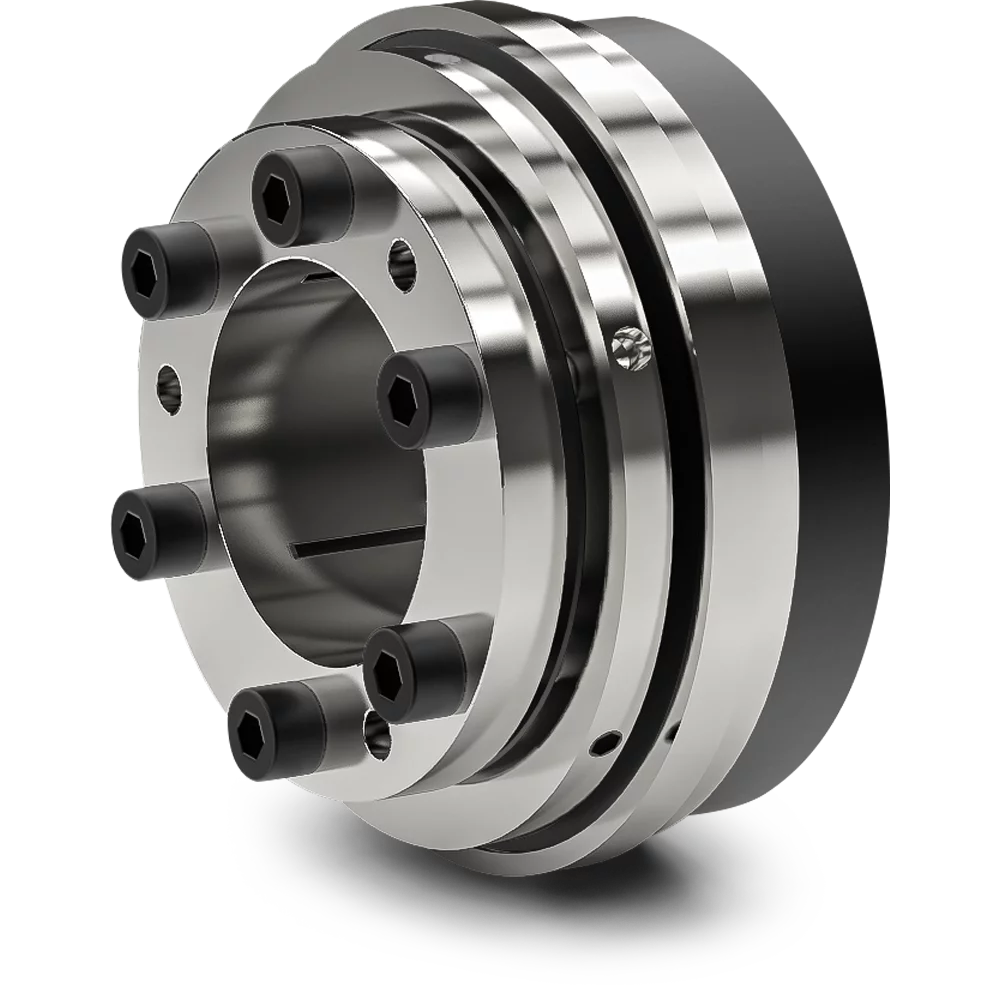

Product Description

Product Description

E-ASIA Bearing ,The rolling element of bearing is taper roller, cone roller bearing inner circle has tapered roller.Conical extension all the to the same point on the axis bearing, tapered roller bearings belong to the body bearing, our company can according to customer’s special requirements, and design production, can provide a metric system size and non-standard bearings.

Tapered roller bearing can be a direction under high load, radial and axial practical in low and middle speed aspect, we are able to offer the following range of bearings: single row, double row, four column type, precision for PO and level P6.

| Name: | 1688 Factory Rolamentos Rodamientos Rulman Single Row 32305 32303 11749 44649 11949 Auto Automotive Wheel Hub Metric Inch Taper Tapered Roller Bearing |

| Model No. | 32305 32303 11749 44649 11949 |

| Type: | Tapered Roller Bearing/Taper Roller Bearing |

| Weight: | Standard weight |

| Specifications: | Standard size |

| Material: | Chrome steel GCR-15 |

| CAGE: | Steel Cage and Nylon Cage |

| Rolling body: | Roller |

Features and Benefits:

1. Low friction and running temperatures, low noise, and vibration

2. High running speeds

3. High quality and performance capabilities for your application

4. Accommodate radial loads and axial loads in both directions

5. Available with a variety of greases for most conditions, including food quality grease, high-temperature grease, and CHINAMFG Oil

6. Increased reliability and provide long bearing and lubricant service life

Product Parameters

| Our Main products | ||

| 1.Chassic Parts | Bearings | Clutch Release Bearings |

| Tensioner Bearings/Pivot shaft | ||

| wheel bearings | ||

| Wheel Hub Units | ||

| Suspension Parts | Shock Absorber | |

| universal Joint/ universal Joint | ||

| Half Shaft | ||

| Steering parts | Steering Pump | |

| Steering Gear | ||

| 2.Clutch&Braking Systerm | Clucth Cylinders | Clutch Master Cylinders |

| Clutch Slave Cyllinders | ||

| Brake Cylinders | Brake Master Cylinders | |

| Brake Slave Cylinders | ||

| 3.Electric Parts | Ignition systems | ignition coils |

| ignition wire set | ||

| Spark Plug | ||

| Exhaust system | Exhaust gas recirculation control valve | |

| EGR(exhaust gas recirculation)valve | ||

| Air flow meter | ||

| Electronic fuel injection system components | Oxygen sensor | |

| Electric throttle position sensor | ||

| Fuel Pump | ||

| fuel injector Nozzle | ||

| air flow sensor | ||

| Crankshaft position sensor | ||

| Camshaft location sensor | ||

| Idle speed switch | ||

| Detonation sensor | ||

| fuel Pressure sensor | ||

| Fan resistance | ||

Same Series Bearings We Offer:

| 80571AC | 566425.H195 | VKBA5423 |

| 581079AC | 566426.H195 | VKBA5424 |

| 85715AC | 566427.H195 | VKBA5425 |

| 85710B | 566283.H195 | VKBA5314 |

| 85710.07 | 566074.H195 | VKBA5316 |

| 805092C | 566834.H195 | VKBA5408 |

| 85714A | 566830.H195 | VKBA5409 |

| 85714.26 | 57571.H195 | VKBA5377 |

| 805092.07 | 568968.H195 | VKBA5379 |

| 805003A.H195 | 571762.H195 | VKBA5549 |

| 85718 | 566834.H195 | VKBA5412 |

| 85712 | 564734.H195 | VKBA5415 |

| 805415 | 572813A | BTH-0571 |

| 801400 | 567549 | BTH-0018 |

| 801794B | 528983A | BTH-0571 |

| 801974A.H195 | 528983B | BTH-0053 |

| 85712A | 534565 | BTH-0055 |

| 85713 | 528946 | BTH-0068 |

| 803628 | 568879 | BTH-0072 |

| 805011C | 543562 | BTH-0073 |

| 805248 | 538971 | BTH-0074 |

| 801961.15 | 85713 | BTH-0087 |

| 805008.08 | BTH-0084 | |

| BTH-0822 |

Our Advantages

1. World-Class Bearing: We provide our customers with all types of indigenous bearing with world-class quality.

2. OEM or Non-Stand Bearings: Any requirement for Nonstandard bearings is Easily Fulfilled by us due to its vast knowledge and links in the industry.

3. Genuine products With Excellent Quality: The company has always proved the 100% quality products it provides with genuine intent.

4. After Sales Service and Technical Assistance: The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

5. Quick Delivery: The company provides just-in-time delivery with its streamlined supply chain.

SAMPLES

1. Samples quantity: 1-10 PCS are available.

2. Free samples: It depends on the Model No., material and quantity. Some of the bearings samples need client to pay samples charge and shipping cost.

3. It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1. MOQ: 10 PCS standard bearings.

2. MOQ: 1000 PCS customized your brand bearings.

OEM POLICY

1. We can printing your brand (logo, artwork)on the shield or laser engraving your brand on the shield.

2. We can custom your packaging according to your design

3. All copyright own by clients and we promised don’t disclose any info.

2. OEM or Non-Stand Bearings: Any requirement for Nonstandard bearings is Easily Fulfilled by us due to its vast knowledge and links in the industry.

3. Genuine products With Excellent Quality: The company has always proved the 100% quality products it provides with genuine intent.

4. After Sales Service and Technical Assistance: The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

5. Quick Delivery: The company provides just-in-time delivery with its streamlined supply chain.

FAQ

SAMPLES

1. Samples quantity: 1-10 PCS are available.

2. Free samples: It depends on the Model No., material and quantity. Some of the bearings samples need client to pay samples charge and shipping cost.

3. It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1. MOQ: 10 PCS standard bearings.

2. MOQ: 1000 PCS customized your brand bearings.

OEM POLICY

1. We can printing your brand (logo, artwork)on the shield or laser engraving your brand on the shield.

2. We can custom your packaging according to your design

3. All copyright own by clients and we promised don’t disclose any info.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Non-Customized |

|---|---|

| Standard Parts: | Yes |

| Universal: | Yes |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you provide insights into the importance of proper tensioner roller alignment?

Proper tensioner roller alignment is of utmost importance in a belt drive system as it directly affects the system’s functionality, performance, and longevity. Here are detailed insights into the importance of proper tensioner roller alignment:

1. Optimal Belt Tension:

Proper tensioner roller alignment ensures optimal belt tension, which is crucial for the efficient operation of the belt drive system. When the tensioner roller is correctly aligned, it applies the appropriate tension to the belt, keeping it properly tensioned and preventing excessive slack or tightness. Optimal belt tension ensures efficient power transfer, minimizes belt slippage, reduces wear on the belt and other components, and maximizes the overall performance of the system.

2. Prevents Belt Misalignment:

Tensioner roller alignment plays a vital role in preventing belt misalignment. Misalignment occurs when the belt deviates from its intended path, causing it to run off-center or make contact with adjacent components. Improper tensioner roller alignment can introduce lateral forces on the belt, leading to misalignment. Belt misalignment can result in reduced power transmission efficiency, increased wear on the belt and pulleys, and the generation of noise and vibrations. Proper tensioner roller alignment helps maintain the belt’s alignment, ensuring smooth operation and minimizing the risk of misalignment-related issues.

3. Reduces Belt Wear and Failure:

Proper tensioner roller alignment helps minimize belt wear and failure. Misalignment can cause the belt to rub against the pulleys or other components, resulting in accelerated wear and damage to the belt. Excessive wear can lead to belt stretching, cracking, or even premature failure. By ensuring proper tensioner roller alignment, the belt remains in its intended position, reducing friction, wear, and the risk of belt failure. This extends the lifespan of the belt and minimizes the need for frequent replacements, resulting in cost savings and improved system reliability.

4. Minimizes Noise and Vibration:

Correct tensioner roller alignment contributes to reduced noise and vibration levels in the belt drive system. Misalignment can cause the belt to oscillate, vibrate, or produce noise as it rubs against the pulleys or other components. These vibrations and noise can be transmitted throughout the system, leading to discomfort, increased wear on components, and a decrease in overall system efficiency. Proper tensioner roller alignment ensures smooth belt operation, minimizing vibrations and noise, and providing a quieter and more comfortable working environment.

5. Improves System Efficiency:

Proper tensioner roller alignment improves the overall efficiency of the belt drive system. Misalignment can result in energy losses due to increased friction, belt slippage, or inefficient power transfer. When the tensioner roller is correctly aligned, it helps maintain optimal belt contact with the pulleys, reducing energy losses and ensuring efficient power transmission. Improved system efficiency leads to reduced energy consumption, increased productivity, and cost savings over the long term.

6. Ensures Reliable Performance:

Tensioner roller alignment is critical for ensuring reliable performance of the belt drive system. Misalignment can lead to unexpected system failures, breakdowns, or unplanned downtime. Proper tensioner roller alignment helps maintain the overall stability and reliability of the system, reducing the risk of sudden failures or disruptions. By ensuring reliable performance, proper tensioner roller alignment contributes to increased productivity, improved operational efficiency, and enhanced system longevity.

7. Facilitates Maintenance and Service:

Proper tensioner roller alignment simplifies maintenance and service tasks. When the tensioner roller is correctly aligned, it is easier to access and adjust, allowing for straightforward tension adjustments or replacement when necessary. Maintenance personnel can quickly identify and address any alignment issues, ensuring that the system remains in optimal working condition. Proper tensioner roller alignment facilitates efficient maintenance practices, reduces downtime during servicing, and enhances the overall serviceability of the belt drive system.

In summary, proper tensioner roller alignment is crucial for the optimal performance, longevity, and reliability of a belt drive system. It ensures optimal belt tension, prevents misalignment, reduces wear on the belt, minimizes noise and vibration, improves system efficiency, and facilitates maintenance and service. By giving due attention to tensioner roller alignment, system operators can maximize the benefits of their belt drive systems and avoid potential issues that can arise from misalignment.

Can tensioner rollers be customized for specific industries or machinery configurations?

Yes, tensioner rollers can be customized to suit specific industries or machinery configurations. The ability to customize tensioner rollers allows for optimal performance and compatibility with unique requirements. Here are some aspects to consider:

1. Size and Dimensions:

Tensioner rollers can be customized to meet specific size and dimensional requirements. This includes variations in diameter, width, and overall dimensions to ensure proper fit and alignment within the machinery or system. Custom sizing ensures that the tensioner roller integrates seamlessly with other components and accommodates the available space constraints.

2. Load Capacity:

Industries and machinery configurations can have varying load capacities based on the application’s demands. Customized tensioner rollers can be designed to handle specific load requirements, ensuring they can support the intended loads without compromising performance or longevity. This customization helps prevent premature wear or failure due to excessive loads.

3. Material Selection:

Tensioner rollers can be customized by selecting materials that are best suited for the specific industry or machinery configuration. Different materials offer varying properties such as strength, durability, resistance to heat, chemicals, or abrasion. Customization allows for the selection of materials that can withstand the unique environmental conditions and operational demands of the application.

4. Coatings and Surface Treatments:

Customization of tensioner rollers also includes the application of coatings or surface treatments to enhance their performance and durability. Coatings such as ceramic, rubber, or Teflon can provide increased wear resistance, reduce friction, and improve the lifespan of the tensioner roller. Customized surface treatments can enhance corrosion resistance or provide specific surface properties required for the application.

5. Mounting and Adjustment Mechanisms:

Tensioner rollers can be customized to incorporate specific mounting and adjustment mechanisms based on the machinery or system configuration. This includes options for adjustable mounting positions, tension adjustment features, or quick-release mechanisms for easy installation, maintenance, and tension adjustments. Customized mounting and adjustment mechanisms ensure optimal functionality and ease of use.

6. Special Features and Accessories:

Depending on the industry or machinery requirements, tensioner rollers can be customized with special features and accessories. These may include additional bearings, seals, or guards to enhance protection, improve performance, or meet specific safety standards. Customized tensioner rollers can also incorporate sensors or monitoring systems to enable condition monitoring and predictive maintenance.

7. Compliance with Industry Standards:

Customized tensioner rollers can be designed to comply with specific industry standards, regulations, or certifications. Industries such as automotive, aerospace, or food processing may have stringent requirements that need to be met. Customization ensures that tensioner rollers meet the necessary standards and provide reliable performance within the specified guidelines.

In summary, tensioner rollers can be customized to suit specific industries or machinery configurations. Customization allows for tailoring the size, load capacity, material selection, coatings, mounting mechanisms, special features, and compliance with industry standards. By customizing tensioner rollers, industries can ensure optimal performance, longevity, and compatibility with their unique requirements.

Can you describe the benefits of using tensioner rollers for optimal belt performance?

Using tensioner rollers in a belt drive system offers several benefits that contribute to optimal belt performance. Here’s a detailed description of the advantages of using tensioner rollers:

1. Maintaining Proper Belt Tension:

Tensioner rollers play a crucial role in maintaining the proper tension of belts within a drive system. They apply the necessary force to keep the belts taut, preventing slack and ensuring optimal power transmission. By maintaining proper tension, tensioner rollers help prevent belt slippage, which can result in the inefficient operation of engine accessories, reduced power output, and increased wear on the belts and other components.

2. Preventing Belt Misalignment:

Tensioner rollers also help prevent belt misalignment. When belts are not properly aligned, they can rub against other components, causing friction and wear. Misalignment can lead to excessive heat generation, noise, and even belt failure. Tensioner rollers, by maintaining the correct tension, help keep the belts aligned and running smoothly, minimizing the risk of misalignment-related issues.

3. Absorbing Belt Vibrations:

Belts in a drive system can experience vibrations due to various factors such as engine operation, load changes, or belt stretch. These vibrations can adversely affect belt performance and increase stress on the system. Tensioner rollers, with their spring-loaded design, help absorb belt vibrations and provide stability to the belt drive system. By dampening vibrations, tensioner rollers contribute to smoother and quieter operation.

4. Compensating for Belt Stretch and Wear:

Over time, belts can stretch or experience wear due to continuous use and exposure to various elements. Tensioner rollers are designed to compensate for belt stretch and wear by automatically adjusting their position. They help maintain the proper tension in the belts, compensating for any elongation or reduction in belt length. This self-adjusting feature ensures consistent belt tension throughout the lifespan of the belts, promoting optimal performance and longevity.

5. Improving Belt Lifespan:

By maintaining proper tension, reducing vibrations, and preventing misalignment, tensioner rollers contribute to the longevity of belts. When belts are under the correct tension and run smoothly, they experience less stress and wear, resulting in an extended lifespan. Using tensioner rollers helps protect the belts from premature failure, reducing the need for frequent belt replacements and minimizing downtime and maintenance costs.

6. Enhancing Overall System Efficiency:

Optimal belt performance achieved through the use of tensioner rollers translates into improved system efficiency. When belts are properly tensioned and aligned, power transmission between the engine and various accessories or components becomes more efficient. This can result in enhanced overall system performance, improved fuel efficiency, and reduced energy losses, leading to cost savings and better utilization of resources.

7. Simplifying Maintenance:

Tensioner rollers can simplify maintenance tasks in belt drive systems. Their self-adjusting capabilities reduce the need for frequent manual adjustments to maintain proper tension. Additionally, tensioner rollers are often equipped with visual indicators or markings that allow for easy inspection of their condition. This simplifies maintenance checks, making it easier to identify worn or damaged tensioner rollers and replace them promptly, ensuring the continued optimal performance of the belt drive system.

In summary, using tensioner rollers in a belt drive system offers numerous benefits for optimal belt performance. These include maintaining proper belt tension, preventing misalignment, absorbing vibrations, compensating for belt stretch and wear, improving belt lifespan, enhancing overall system efficiency, and simplifying maintenance. Incorporating tensioner rollers into a belt drive system is essential for maximizing performance, minimizing downtime, and ensuring reliable operation of the system.

editor by CX 2024-01-30

China factory Auto Parts Bearing Motorcycle Parts Bearing Car Accessories Bearing Auto Spare Part Bearing Spare Parts Bearing Engine Parts Bearing Wheel Bearing Taper Roller

Product Description

Product Description

E-ASIA Bearing ,The rolling element of bearing is taper roller, cone roller bearing inner circle has tapered roller.Conical extension all the to the same point on the axis bearing, tapered roller bearings belong to the body bearing, our company can according to customer’s special requirements, and design production, can provide a metric system size and non-standard bearings.

Tapered roller bearing can be a direction under high load, radial and axial practical in low and middle speed aspect, we are able to offer the following range of bearings: single row, double row, four column type, precision for PO and level P6.

| Name: | 1688 Factory Rolamentos Rodamientos Rulman Single Row 32305 32303 11749 44649 11949 Auto Automotive Wheel Hub Metric Inch Taper Tapered Roller Bearing |

| Model No. | 32305 32303 11749 44649 11949 |

| Type: | Tapered Roller Bearing/Taper Roller Bearing |

| Weight: | Standard weight |

| Specifications: | Standard size |

| Material: | Chrome steel GCR-15 |

| CAGE: | Steel Cage and Nylon Cage |

| Rolling body: | Roller |

Features and Benefits:

1. Low friction and running temperatures, low noise, and vibration

2. High running speeds

3. High quality and performance capabilities for your application

4. Accommodate radial loads and axial loads in both directions

5. Available with a variety of greases for most conditions, including food quality grease, high-temperature grease, and CHINAMFG Oil

6. Increased reliability and provide long bearing and lubricant service life

Product Parameters

| Our Main products | ||

| 1.Chassic Parts | Bearings | Clutch Release Bearings |

| Tensioner Bearings/Pivot shaft | ||

| wheel bearings | ||

| Wheel Hub Units | ||

| Suspension Parts | Shock Absorber | |

| universal Joint/ universal Joint | ||

| Half Shaft | ||

| Steering parts | Steering Pump | |

| Steering Gear | ||

| 2.Clutch&Braking Systerm | Clucth Cylinders | Clutch Master Cylinders |

| Clutch Slave Cyllinders | ||

| Brake Cylinders | Brake Master Cylinders | |

| Brake Slave Cylinders | ||

| 3.Electric Parts | Ignition systems | ignition coils |

| ignition wire set | ||

| Spark Plug | ||

| Exhaust system | Exhaust gas recirculation control valve | |

| EGR(exhaust gas recirculation)valve | ||

| Air flow meter | ||

| Electronic fuel injection system components | Oxygen sensor | |

| Electric throttle position sensor | ||

| Fuel Pump | ||

| fuel injector Nozzle | ||

| air flow sensor | ||

| Crankshaft position sensor | ||

| Camshaft location sensor | ||

| Idle speed switch | ||

| Detonation sensor | ||

| fuel Pressure sensor | ||

| Fan resistance | ||

Same Series Bearings We Offer:

| 80571AC | 566425.H195 | VKBA5423 |

| 581079AC | 566426.H195 | VKBA5424 |

| 85715AC | 566427.H195 | VKBA5425 |

| 85710B | 566283.H195 | VKBA5314 |

| 85710.07 | 566074.H195 | VKBA5316 |

| 805092C | 566834.H195 | VKBA5408 |

| 85714A | 566830.H195 | VKBA5409 |

| 85714.26 | 57571.H195 | VKBA5377 |

| 805092.07 | 568968.H195 | VKBA5379 |

| 805003A.H195 | 571762.H195 | VKBA5549 |

| 85718 | 566834.H195 | VKBA5412 |

| 85712 | 564734.H195 | VKBA5415 |

| 805415 | 572813A | BTH-0571 |

| 801400 | 567549 | BTH-0018 |

| 801794B | 528983A | BTH-0571 |

| 801974A.H195 | 528983B | BTH-0053 |

| 85712A | 534565 | BTH-0055 |

| 85713 | 528946 | BTH-0068 |

| 803628 | 568879 | BTH-0072 |

| 805011C | 543562 | BTH-0073 |

| 805248 | 538971 | BTH-0074 |

| 801961.15 | 85713 | BTH-0087 |

| 805008.08 | BTH-0084 | |

| BTH-0822 |

Our Advantages

1. World-Class Bearing: We provide our customers with all types of indigenous bearing with world-class quality.

2. OEM or Non-Stand Bearings: Any requirement for Nonstandard bearings is Easily Fulfilled by us due to its vast knowledge and links in the industry.

3. Genuine products With Excellent Quality: The company has always proved the 100% quality products it provides with genuine intent.

4. After Sales Service and Technical Assistance: The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

5. Quick Delivery: The company provides just-in-time delivery with its streamlined supply chain.

SAMPLES

1. Samples quantity: 1-10 PCS are available.

2. Free samples: It depends on the Model No., material and quantity. Some of the bearings samples need client to pay samples charge and shipping cost.

3. It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1. MOQ: 10 PCS standard bearings.

2. MOQ: 1000 PCS customized your brand bearings.

OEM POLICY

1. We can printing your brand (logo, artwork)on the shield or laser engraving your brand on the shield.

2. We can custom your packaging according to your design

3. All copyright own by clients and we promised don’t disclose any info.

2. OEM or Non-Stand Bearings: Any requirement for Nonstandard bearings is Easily Fulfilled by us due to its vast knowledge and links in the industry.

3. Genuine products With Excellent Quality: The company has always proved the 100% quality products it provides with genuine intent.

4. After Sales Service and Technical Assistance: The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

5. Quick Delivery: The company provides just-in-time delivery with its streamlined supply chain.

FAQ

SAMPLES

1. Samples quantity: 1-10 PCS are available.

2. Free samples: It depends on the Model No., material and quantity. Some of the bearings samples need client to pay samples charge and shipping cost.

3. It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1. MOQ: 10 PCS standard bearings.

2. MOQ: 1000 PCS customized your brand bearings.

OEM POLICY

1. We can printing your brand (logo, artwork)on the shield or laser engraving your brand on the shield.

2. We can custom your packaging according to your design

3. All copyright own by clients and we promised don’t disclose any info.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Non-Customized |

|---|---|

| Standard Parts: | Yes |

| Universal: | Yes |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do electronic or computer-controlled tensioner rollers enhance belt system performance?

Electronic or computer-controlled tensioner rollers offer advanced features and capabilities that enhance the performance of belt systems in vehicles. These innovative tensioner rollers utilize electronic sensors, actuators, and control algorithms to optimize tension, alignment, and overall operation. Here’s a detailed explanation of how electronic or computer-controlled tensioner rollers enhance belt system performance:

1. Real-Time Tension Control:

Electronic tensioner rollers continuously monitor the tension in the belt and can adjust it in real-time. Using sensors and feedback mechanisms, these tensioner rollers measure the tension and communicate with the control unit to make precise adjustments. Real-time tension control ensures that the belt remains within the optimal tension range, minimizing the risk of slippage or excessive tension that could lead to premature wear or belt failure.

2. Adaptive Belt Alignment:

Computer-controlled tensioner rollers can also monitor and adjust the alignment of the belt. By analyzing sensor data and using actuators, these tensioner rollers can make small adjustments to correct any misalignment. Adaptive belt alignment helps ensure that the belt remains properly aligned with the pulleys, reducing wear, noise, and power losses associated with misalignment. It contributes to improved belt system performance and longevity.

3. Load Compensation:

Electronic tensioner rollers can dynamically adjust the tension based on the load or operating conditions. By analyzing inputs from various sensors, such as engine load, temperature, or accessory demands, these tensioner rollers can adapt the tension to optimize performance and efficiency. Load compensation ensures that the belt system operates optimally under different load scenarios, enhancing overall drivability and preventing belt-related issues.

4. Integrated Belt Health Monitoring:

Some electronic tensioner rollers feature integrated belt health monitoring capabilities. They utilize sensors to measure parameters such as belt wear, temperature, or vibration. By continuously monitoring the belt’s condition, these tensioner rollers can provide early warning signs of potential belt failures or maintenance needs. Integrated belt health monitoring helps prevent unexpected belt failures, improve maintenance planning, and optimize the performance and reliability of the belt system.

5. Diagnostic Capabilities:

Electronic or computer-controlled tensioner rollers often have diagnostic capabilities that can communicate with the vehicle’s onboard computer system. They can provide diagnostic information, fault codes, or performance data, allowing technicians to troubleshoot and address belt system issues more efficiently. Diagnostic capabilities contribute to quicker and more accurate diagnosis, reducing downtime, and improving overall belt system performance.

6. System Integration:

Electronic tensioner rollers can be integrated into the vehicle’s overall electronic control system. They can communicate and coordinate with other components, such as the engine management system or accessory controllers. This integration allows for optimized operation and coordination between the belt system and other vehicle systems, improving drivability, efficiency, and performance.

7. Advanced Control Algorithms:

Computer-controlled tensioner rollers employ advanced control algorithms to optimize tension, alignment, and other parameters. These algorithms take into account various inputs, such as engine speed, load, temperature, and system requirements, to determine the optimal operating conditions for the belt system. The use of advanced control algorithms ensures precise and efficient operation, contributing to enhanced belt system performance.

In summary, electronic or computer-controlled tensioner rollers enhance belt system performance by providing real-time tension control, adaptive belt alignment, load compensation, integrated belt health monitoring, diagnostic capabilities, system integration, and advanced control algorithms. These features optimize the operation of the belt system, improve drivability, reduce maintenance needs, and enhance the overall performance and reliability of the vehicle’s belt-driven systems.

What factors should be considered when selecting tensioner rollers for different industrial applications?

When selecting tensioner rollers for different industrial applications, several factors need to be taken into consideration. These factors include:

1. Load and Tension Requirements:

The load and tension requirements of the specific industrial application are crucial factors to consider. It is important to determine the maximum load the tensioner roller will experience and the required tension for proper belt operation. This information helps in selecting a tensioner roller that can handle the anticipated loads and provide the necessary tension to prevent belt slippage or excessive wear.

2. Belt Type and Size:

The type and size of the belt being used in the industrial application are important considerations. Different belts have varying characteristics, such as width, thickness, and tooth profile. It is essential to choose a tensioner roller that is compatible with the specific belt type and size to ensure proper fit, alignment, and tension distribution.

3. Operating Speed:

The operating speed of the industrial application is a critical factor when selecting tensioner rollers. High-speed applications generate centrifugal forces that can impact belt tension and introduce vibrations. Tensioner rollers designed for high-speed applications are typically equipped with features to absorb vibrations and maintain consistent tension, ensuring reliable power transmission at elevated speeds.

4. Environmental Conditions:

The environmental conditions in which the tensioner roller will operate should be considered. Factors such as temperature extremes, humidity, dust, dirt, chemicals, and exposure to moisture or corrosive substances can affect the performance and durability of the tensioner roller. Selecting a tensioner roller with appropriate materials and protective coatings ensures its reliability and longevity in the specific environmental conditions.

5. Alignment and Adjustment Mechanism:

The alignment and adjustment mechanism of the tensioner roller play a crucial role in maintaining proper belt tension. Consider the ease of installation, adjustment, and alignment when selecting a tensioner roller. Look for features such as adjustable mounting positions, tension adjustment mechanisms, and reliable locking mechanisms that facilitate easy and precise tension adjustment and alignment of the belt.

6. Maintenance and Serviceability:

The maintenance and serviceability aspects of the tensioner roller should be taken into account. Evaluate the accessibility of the tensioner roller for inspection, lubrication, and maintenance tasks. Choose a tensioner roller that allows for easy replacement of worn or damaged components, minimizing downtime and maintenance costs in the industrial application.

7. Compatibility with the System:

Ensure that the tensioner roller is compatible with the overall belt drive system and other components in the industrial application. Consider factors such as the mounting arrangement, space constraints, and integration with other system elements. Compatibility ensures proper fit, functionality, and overall system performance.

8. Industry Standards and Regulations:

Complying with industry standards and regulations is essential when selecting tensioner rollers for industrial applications. Consider any specific requirements or guidelines set by relevant regulatory bodies or industry associations. Adhering to these standards helps ensure safety, reliability, and compliance with applicable regulations.

In summary, when selecting tensioner rollers for different industrial applications, it is important to consider factors such as load and tension requirements, belt type and size, operating speed, environmental conditions, alignment and adjustment mechanism, maintenance and serviceability, compatibility with the system, and adherence to industry standards and regulations. Considering these factors ensures the appropriate selection of tensioner rollers that will effectively support the belt drive system and optimize the performance and reliability of the industrial application.

Can you describe the benefits of using tensioner rollers for optimal belt performance?

Using tensioner rollers in a belt drive system offers several benefits that contribute to optimal belt performance. Here’s a detailed description of the advantages of using tensioner rollers:

1. Maintaining Proper Belt Tension:

Tensioner rollers play a crucial role in maintaining the proper tension of belts within a drive system. They apply the necessary force to keep the belts taut, preventing slack and ensuring optimal power transmission. By maintaining proper tension, tensioner rollers help prevent belt slippage, which can result in the inefficient operation of engine accessories, reduced power output, and increased wear on the belts and other components.

2. Preventing Belt Misalignment:

Tensioner rollers also help prevent belt misalignment. When belts are not properly aligned, they can rub against other components, causing friction and wear. Misalignment can lead to excessive heat generation, noise, and even belt failure. Tensioner rollers, by maintaining the correct tension, help keep the belts aligned and running smoothly, minimizing the risk of misalignment-related issues.

3. Absorbing Belt Vibrations:

Belts in a drive system can experience vibrations due to various factors such as engine operation, load changes, or belt stretch. These vibrations can adversely affect belt performance and increase stress on the system. Tensioner rollers, with their spring-loaded design, help absorb belt vibrations and provide stability to the belt drive system. By dampening vibrations, tensioner rollers contribute to smoother and quieter operation.

4. Compensating for Belt Stretch and Wear:

Over time, belts can stretch or experience wear due to continuous use and exposure to various elements. Tensioner rollers are designed to compensate for belt stretch and wear by automatically adjusting their position. They help maintain the proper tension in the belts, compensating for any elongation or reduction in belt length. This self-adjusting feature ensures consistent belt tension throughout the lifespan of the belts, promoting optimal performance and longevity.

5. Improving Belt Lifespan:

By maintaining proper tension, reducing vibrations, and preventing misalignment, tensioner rollers contribute to the longevity of belts. When belts are under the correct tension and run smoothly, they experience less stress and wear, resulting in an extended lifespan. Using tensioner rollers helps protect the belts from premature failure, reducing the need for frequent belt replacements and minimizing downtime and maintenance costs.

6. Enhancing Overall System Efficiency:

Optimal belt performance achieved through the use of tensioner rollers translates into improved system efficiency. When belts are properly tensioned and aligned, power transmission between the engine and various accessories or components becomes more efficient. This can result in enhanced overall system performance, improved fuel efficiency, and reduced energy losses, leading to cost savings and better utilization of resources.

7. Simplifying Maintenance:

Tensioner rollers can simplify maintenance tasks in belt drive systems. Their self-adjusting capabilities reduce the need for frequent manual adjustments to maintain proper tension. Additionally, tensioner rollers are often equipped with visual indicators or markings that allow for easy inspection of their condition. This simplifies maintenance checks, making it easier to identify worn or damaged tensioner rollers and replace them promptly, ensuring the continued optimal performance of the belt drive system.

In summary, using tensioner rollers in a belt drive system offers numerous benefits for optimal belt performance. These include maintaining proper belt tension, preventing misalignment, absorbing vibrations, compensating for belt stretch and wear, improving belt lifespan, enhancing overall system efficiency, and simplifying maintenance. Incorporating tensioner rollers into a belt drive system is essential for maximizing performance, minimizing downtime, and ensuring reliable operation of the system.

editor by CX 2023-12-19

China manufacturer Tensioner Timing Bearing 05142798AA Vkm18601 Vkm19601 for Chrysler Voyager and Jeep Cherokee Engine Parts with Best Sales

Product Description

Quick view:

| Description | Tensioner timing bearing 5712798AA VKM18601 VKM19601 For CHRYSLER VOYAGER And JEEP CHEROKEE Engine parts | |||

| Material | Chrome steel Gcr15, 65Mn, or 55, Aluminum | |||

| Application car makes | For JEEP For DODGE For CHRYSLER |

|||

| Size | Outer: 66 mm Width: 32 mm |

|||

| Position | Tension | |||

| Weight | 0.5 kg | |||

| Brand | SI, PPB, or customized | |||

| Packing | Neutral, SI, PPB brand packing or customized | |||

| OEM/ODM service | Yes | |||

| Manufacture place | ZHangZhoug, China | |||

| MOQ | 1 | Kia | ||

| B660-12-7 | Mazda | |||

| RFC6-12-7 | Mazda | |||

| F801-12-7 | Mazda | |||

| FE1H-12-7 | Mazda | |||

| WL01-12-7 | Mitsubishi | |||

| MD315265 | VKM75 | Mitsubishi | ||

| 24410-26 | Mitsubishi | |||

| MD169592 | VKM75 | Mitsubishi | ||

| MD115976 | VKM75044 | CR5073 | F-554646 | Mitsubishi |

| MD182537 | VKM75064 | CR5078 | Mitsubishi | |

| MD030605 | VKM751 | Mitsubishi | ||

| MD129355 | VKM75101 | CR5070 | Mitsubishi | |

| 23357-32040 | VKM75113 | CR5071 | F-124078 | Hyundai |

| MD | Mitsubishi | |||

| MD129033 | VKM75130 | CR5084 | Mitsubishi | |

| 24450-33571 | VKM75144 | CR5067 | Hyundai | |

| 23357-42571 | VKM75601 | CR5076 | F-124070 | Hyundai |

| 24317-42571 | VKM75612 | CR5077 | F-124052 | Hyundai |

| 24317-42571 | VKM75612 | CR5077 | F-124052 | Hyundai |

| MD352473 | VKM75613 | CR5171 | Mitsubishi | |

| MD329976 | VKM75615 | CR5172 | Mitsubishi | |

| MD320174 | VKM75616 | CR5137 | Mitsubishi | |

| 24410-57150 | VKM75621 | CR5225 | Hyundai | |

| MD356509 | VKM75625 | CR5206 | Mitsubishi | |

| 12810-71C02 | VKM76 | SUZUKI | ||

| 12810-81401- | SUZUKI | |||

| 12810-86501 | VKM76203 | CR5101 | SUZUKI | |

| 13505-87702- | S ubaru | |||

| 8-94472-349- 1 |

VKM79.1 | Daewoo | ||

| 13503-62030 | VKM81 | Toyota | ||

| 13503-54571 | VKM81 | Toyota | ||

| 13503-54030 | VKM81 | Toyota | ||

| 13503-10571 | VKM81201 | CR5026 | F-124073 | Toyota |

| 13503-1571 | VKM81203 | CR5571 | F-124089 | Toyota |

| 13503-11040 | VKM814 | Toyota | ||

| 13074-05E | Nissan | |||

| 13077-V7202 | VKM825 | Nissan | ||

| FS01-12-730A | VKM84 | Mazda | ||

| FE1H-12-730A | VKM846 | Mazda | ||

| OK972-12-730 | VKM84601 | CR5055 | Kia | |

| 24810-33571 | VKM85 | I suzu | ||

| 9281571212 | CR3395 | F-22 | Fiat / Lancia | |

| 57119243L | VKM11107 | CR3467 | F-55571 | Audi / VW |

| 1112571119 | VKM23063S | CR1458 | F-220122 | Mercedes Benz |

| CR3416 | PSA | |||

| 7784613 | CR1440P | F-123753 | Fiat / Lancia | |

| CR1452P | Fiat / Lancia | |||

| 601257170 | CR1477 | F-220124 | Mercedes Benz | |

| CR1478 | ||||

| CR1480 | O pel / GM | |||

| CR1480P | O pel / GM | |||

| 715713 | CR1481 | FORD | ||

| CR1484 | Fiat / Lancia | |||

| 90324097 | CR1486 | F-225717 | O pel / GM | |

| CR1497 | Fiat / Lancia | |||

| CR1498 | Fiat / Lancia | |||

| CR1499 | FORD | |||

| 7301662 | CR1647 | F-88019.2 | Fiat / Lancia | |

| 11281731220 | CR3571 | F-225569 | BMW | |

| 11281731838 | CR3571 | F-225633 | BMW | |

| XS4Q6B217AD | CR3102 | F-143 | FORD | |

| 6682571419 | CR3118 | Mercedes Benz | ||

| 668257171 | CR3119 | Mercedes Benz | ||

| 9635638380 | CR3218 | F-123183.18 | R enault | |

| 46547564 | CR3270 | Fiat / Lancia | ||

| 5 | Fiat / Lancia | |||

| 96036288 | CR3276 | F-120676 | PSA | |

| 962 | PSA | |||

| CR3296 | F-123788 | PSA |

ZheJiang Mighty (SI Bearing)are providing deep groove ball bearing, tapered roller bearing, pillow block bearing, spherical roller bearing, angular contact ball bearing, needle bearing, self-aligning ball bearing, linear bearing, wheel hub bearing, hub unit, clutch release bearing, belt tensioner, etc.

Our Bearing Advantage:

1.Free Sample bearing

2.ISO certified

3.Bearing Small order accepted

4.In Stock bearing

5.OEM bearing service

6.Professional: Over 20 years manufacture bearing

7.Customized bearing, Customer’s bearing drawing or samples accepted

8.Competitive price

9.TT Payment, Paypal, Alibaba payment, Trade Assurance Order

FAQ:

Q: Can you help with my own brand?

A: Sure. We can make for your brands. We can mark your brand name and use your box’s design with the legal authority letter.

Q: How can I make an inquiry?

A: You can contact us by email, telephone, WhatsApp, , etc.

Q: How long can reply inquiry?

A: Within 24 hours.

Q: Which Service you can provide?

A: 1. Help customers to choose correct bearing

2. Professional team, make your purchase easily

Q: When are you going to deliver?

A: Sample: 5-15 business days after payment is confirmed.

Bulk order:15-60 workdays after deposit received…

Q: What’s your delivery way?

A: By sea, by air, by train, express as your need.

Q: What are your terms of delivery?

A: EXW, FOB, CFR, CIF, DAP, etc.

Q: Can you support the sample order?

A: Yes, we can supply the sample if we have parts in stock, but the customer has to pay the sample payment(according to the value of the samples) and the shipping cost.

Q: What are you going to do if there has a claim for the quality or quantity missing?

A: 1. For quality, during the warranty period, if any claim for it, we shall help customer to find out what’s the exactly problem. Using by mistake, installation problem, or poor quality? Once it’s due to the poor quality, we will arrange the new products to customers.

2. For missing quantities, there have 2 weeks for claiming the missing ones after receiving the goods. We shall help to find out where it is.

How to Fix a Faulty Drive Belt Tensioner

If you’re experiencing grinding, squeaking, or other unusual sounds from your car, your drive belt tensioner may be the culprit. In this article, we’ll discuss why a failed drive belt tensioner may need to be replaced and how to fix it. Once you have determined that your belt tensioner is faulty, you can use a Wrench to remove it and replace it with a new one. After you replace the belt tensioner, it will no longer be making noises.

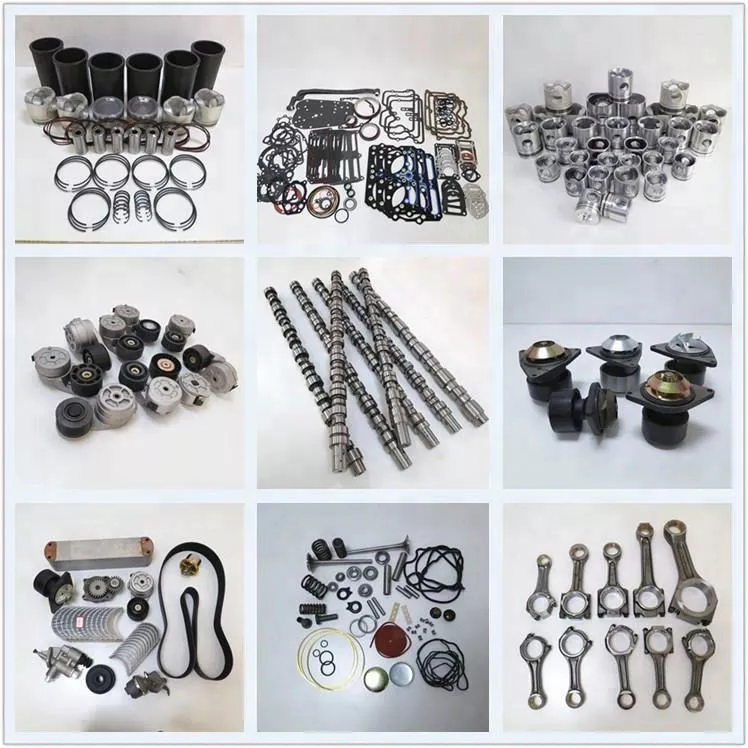

Problems with timing belt tensioner

Whenever your engine is making strange noises, it is likely that the timing belt tensioner is causing the problem. A bad timing belt tensioner is a big cause of such sounds, as the timing of the engine is critical. When the belt is moving properly, the camshaft and crankshaft are perfectly synchronized, and the valves work in perfect sync during the intake and exhaust strokes of each cylinder.

Other signs of a worn tensioner include rust bleeding and dripping. Usually, rust will appear at the mounting bolts and “stops” on the tensioner. Other symptoms of a worn timing belt tensioner are noise, resistance, and roughness. If any of these symptoms are present, it’s important to get the car fixed as soon as possible. Troubleshooting problems with timing belt tensioner is an easy process if you know the symptoms.

If your car starts making squeaking or grinding noises when you drive, it’s probably the timing belt tensioner. The timing belt can also cause problems with your engine’s valves. When the timing belt is too loose, the valves cannot fully combust the fuel-air mixture. If this problem is left undiagnosed, it could result in severe engine damage. To solve the problem, you must replace the timing belt tensioner.

The repair of the timing belt tensioner is not a difficult job if you’re experienced and comfortable with DIY car repairs. If you have a good knowledge of car repair, you can try to replace it yourself – but don’t forget that it is a complex repair job that requires a lot of skill. So, it’s best to hire a professional mechanic. And if you don’t have the necessary tools and training, you can always try the DIY method.

Other symptoms of a bad timing belt tensioner include an abnormal chirping noise, misfiring, and check engine light malfunction. If you notice any of these symptoms, you should replace the timing belt tensioner as soon as possible. Often, the belt is wearing out and can’t spin freely. You may have to replace the timing belt tensioner to avoid major damage to your engine. The best way to tell if the timing belt tensioner is failing is to check it regularly.

Cost of a new drive belt tensioner

A new drive belt can be expensive. Replacing 1 is usually a straightforward task that requires little knowledge, but some cars are more difficult than others. Replacing a drive belt by yourself may result in the replacement of parts you do not know. You may also encounter problems that cannot be resolved unless you have a mechanic check all the affected parts. You can save money by taking the car to a mechanic before trying to fix the problem yourself.

A drive belt tensioner should last at least 125,000 miles, but can break sooner. Most car mechanics will replace the tensioner after you notice the belt is slipping. It takes about 15 minutes to an hour to replace 1 of these parts, and you can do it yourself with the proper tools. You can also ask about the replacement of pulleys or sprockets. The price of a new drive belt tensioner depends on the make and model of your car.

The average cost to replace a drive belt tensioner is between $235 and $267. This cost includes labor and parts, but doesn’t include taxes or fees. Some vehicles may need related repairs as well, such as serpentine belts or tensioner housing. For a detailed estimate, use the RepairPal Fair Price Estimator. You can compare labor costs and shop for the best price. There are many options available online, and you can choose the most convenient 1 for your needs.

In addition to replacing the drive belt, you should also check the idler pulleys, which do not drive anything. If they have excessive movement, replace them. A failed drive belt tensioner can cause the belt to slip and affect other components of the car. You may also notice warning lights that indicate a problem with the alternator, water pump, or power steering. You should also check your vehicle’s air conditioning.

Replacing the tensioner pulley can be done yourself for about $50. Depending on the type of pulley and belt, you may need to replace other parts of the engine as well. You can save money by replacing a tensioner pulley yourself if you have the time and skills. It’s easy to replace a new drive belt tensioner if you’re a mechanically inclined individual.

Repair options for a failed drive belt tensioner

A failed drive belt tensioner may have several symptoms. For instance, it can make a grinding or squealing sound, and it may emit a burning smell. The battery light on your car may also stay on. These are all signs that your drive belt has failed. However, these symptoms are not always indicative of the failure of the drive belt tensioner. Listed below are some common problems that can be caused by a failed drive belt tensioner.

To check for a failed drive belt tensioner, turn off the engine and examine the arm. If it doesn’t move, it’s time to replace the drive belt. A manual drive belt tensioner is easy to replace. A hydraulic or bad spring drive belt tensioner, however, will not be able to be fixed. If you can’t find a repair shop in your area, visit 1 of NAPA AutoCare locations, or a NAPA online store. They will be able to diagnose the failure and provide solutions for your car.

A spring tensioner is a type of drive belt tensioner that uses a spring-loaded pulley to apply the proper tension to the drive belt. However, spring tensioners can fail and seize if not properly maintained. A hydraulic tensioner uses hydraulic oil under pressure and can malfunction. In some cases, the tensioner can leak oil or lose its ability to tension the drive belt. It can also be damaged by excessive wear, which will cause the belt to break.

A failed drive belt tensioner can affect your car’s performance and functionality. In addition to making your car squeaky and jerky, a failed drive belt tensioner can cause the serpentine or v-belt to slip and wear out prematurely. Repairing a failed drive belt tensioner can also prevent your car from experiencing the same problems in the future. So, what do you do if you find your drive belt is slipping?

If your drive belt tensioner isn’t the problem, you’ll have to replace it. In some cases, a loose tensioner arm can lead to cracks in the tensioner housing. In the worst case scenario, the damaged tensioner can also lead to an overheated engine. Ultimately, a failed drive belt tensioner can cause your car to experience overheating, weak battery charging, and even a weakened power steering system.

Maintenance requirements for a drive belt tensioner

Drive belt tensioner maintenance begins with proper alignment of the pulleys. Misaligned pulleys or drives can wear a belt out too fast. Misalignment can occur if the component was recently replaced. A set of shims can restore the pulleys to the proper alignment. It is important to regularly check the tensioner to ensure proper function. Also, check the belt for cracks or wear.

Before performing any maintenance work, always turn off the drive to protect the motor. The belt should be in a safe position so that it will not fall on the workers. Lock down any moving parts and ensure the fans do not freewheel. When inspecting the drive belt tensioner, examine the belt guard for wear and debris. If the belt is damaged or has excessive heat, it is necessary to clean it or replace it.

It is important to maintain a proper fit between the belt and the drive belt tensioner. An incorrectly-sized drive belt will be difficult to install and adjust. An incorrect-rib count drive belt will fit, but will not last as long. Likewise, drive belts with too many ribs will not last as long. For these reasons, drive belt tensioners should be replaced when they are over 50,000 miles.

A drive belt tensioner is a pulley that rides on the outside surface of the serpentine belt. Its purpose is to maintain constant pressure on the pulleys that power car components. It is typically mounted on the front of the engine, bolted to the crankshaft, and rests against the serpentine belt. If the drive belt is cracked, it needs to be replaced immediately. If the arm is loose or bent, the bearings in the tensioner are probably worn.

The drive belt tensioner is an important part of the drive system, which is essential for smooth operation of the vehicle. However, it does wear out prematurely and should be replaced at a certain mileage. It should also be inspected for normal wear and tear as a result of road dirt, excessive heat, and oil leaks. However, it is important to remember that drive belts are highly sensitive to excessive heat, road dirt, and oil leaks.

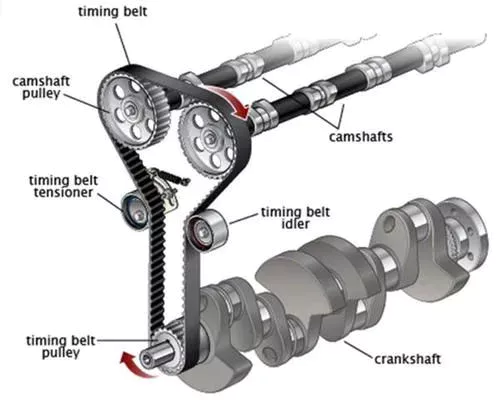

China Standard CZPT China Inch Tapered Roller Bearing Product Auto Spare Parts Tensioner Assy OEM 311705g0a01 Crosstour for Honda 7017AC near me shop

Product Description

HangZhou CZPT CO.,LTD

Factory Add: Pannan Village, Panzhuang Town, HangZhou City, HangZhou City, ZheJiang Province, China

Main Products:

*Deep Groove Ball Bearing

*Self-Aligning Ball Bearing

*Cylindrical Roller Bearings

*Spherical Roller Bearing

*Angular Contact Ball Bearings

*Tapered Roller Bearings

*Thrust Ball Bearing

*Thrust Roller Bearing

*Spherical Bearings

*Thin-Walled Bearings

*Miniature Bearings

*Needle Bearing

XINHUO BEARING CHINA INCH TAPERED ROLLER BEARING PRODUCT AUTO SPARE PARTS TENSIONER ASSY OEM 311705G0A01 CROSSTOUR FOR HONDA 7017AC

Product Description

|

Product Name |

Angular Contact Ball Bearing |

|

Type |

Angular Contact Ball Bearing |

|

Structure |

Angular contact |

|

Applicable Industries |

Machinery manufacturing plant, machine tool, mechanical equipment, motor automobile hub, agricultural machinery |

|

Brand Name |

RPZ /XINHUO/XWFD/ XWFD ZMW |

|

Accuracy class |

P0, P6, P5, P4, P2, or as required20mm-500mm |

|

Seal type |

OPEN / 2RS |

|

Size |

20mm-500mm |

|

Number of Rows |

Single Row |

|

Origin |

ZheJiang , China |

|

Product Model |

7000cac 7200c 7001acm |

|

Material |

GCr15 chrome steel / stainless steel bearing |

|

Features |

Long Life, Low Friction, High Speed |

|

Retainer Type |

Brass / Bakelite / Steel |

| Angular contact bearing | ||||

| 7000AC | 7200AC | 7303AC | 7406AC | 3304-2RS/ZZ |

| 7001AC | 7201AC | 7304AC | 7407ACP6 | 3305-2RS/ZZ |

| 7002AC | 7202AC | 7305AC | 7408AC | 3306-2RS/ZZ |

| 7003AC | 7203AC | 7306AC | 7409AC | 3307-2RS/ZZ |

| 7004AC | 7204AC | 7307AC | 7410AC | 3308-2RS/ZZ |

| 7005AC | 7205AC | 7308AC | 7412ACM | 3309-2RS/ZZ |

| 7006AC | 7206AC | 7309AC | 7412BM | 3310-2RS/ZZ |

| 7007AC | 7207AC | 7310AC | 7414ACM | 3311-2RS/ZZ |

| 7008AC | 7208AC | 7311AC | 7414BM | 3312-2RS/ZZ |

| 7009AC | 7209AC | 7312AC | 7416ACM | 3313-2RS/ZZ |

| 7571AC | 7210C | 7313AC | 7416BM | 3314-2RS/ZZ |

| 7011AC | 7210AC | 7314AC | 7418ACM | 3315-2RS/ZZ |

| 7012AC | 7211AC | 7315AC | 7418BM | 3316-2RS/ZZ |

| 7013AC | 7212AC | 7315BM | 3317-2RS/ZZ | |

| 7014AC | 7213AC | 7317AC | 3204-2RS/ZZ | 3318-2RS/ZZ |

| 7015AC | 7214AC | 7317BM | 3205-2RS/ZZ | 3319-2RS/ZZ |

| 7016AC | 7216AC | 7318AC | 3206-2RS/ZZ | 3320-2RS/ZZ |

| 7017AC | 7217AC | 7318BTN | 3207-2RS/ZZ | |

| 7018AC | 7218AC | 7319AC | 3208-2RS/ZZ | QJ210 |

| 7571AC | 7219AC | 7319BM | 3209-2RS/ZZ | QJ211 |

| 7571AC | 7220AC | 7320AC | 3210-2RS/ZZ | QJ212 |

| 7571AC | 7221AC | 7320BM | 3211-2RS/ZZ | QJ213 |

| 7026AC | 7222AC | 7322AC | 3212-2RS/ZZ | QJ214 |

| 7571AC | 7224AC | 7322BM | 3213-2RS/ZZ | QJ215 |

| 7030AC | 7228AC | 7324ACM | 3214-2RS/ZZ | QJ216 |

| 7032AC | 7232AC | 7324BM | 3215-2RS/ZZ | QJ217 |

| 7034AC | 7236AC | 7326ACM | 3216-2RS/ZZ | QJ218 |

| 7036AC | 7240AC | 7328ACM | 3217-2RS/ZZ | QJ219 |

| 7038AC | 7244AC | 7328BM | 3218-2RS/ZZ | QJ220 |

| 7330ACM | 3219-2RS/ZZ | QJ222 | ||

| 7332ACM | 3220-2RS/ZZ | QJ224 | ||

| 7334ACM | QJ226 | |||

| 7336ACM | QJ228 | |||

| 7338ACM | QJ230 | |||

| 7340ACM | QJ232 | |||

FAQ

Q1:What is your Before-sales Service?

1>. Offer to bear related consultation about technology and application;

2>.Help customers with bearing choice, clearance configuration, products” life and reliability analysis;

3>. Offer highly cost-effective and complete solution program according to site conditions;

4>. Offer localized program on introduced equipment to save running cost

Q2: What is your After-sales Service?

1>. Offer training about bearing installation and maintenance;

2>.Help customers with trouble diagnosis and failure analysis;

3>. Visit customers regularly and feedback their rational suggestions and requirements to the company.

Q3: How about your company’s strength?

1>.FREE SAMPLES:

contact us by email or trade manager, we will send the free samples according to your request.

2>. World-Class Bearing:

We provide our customers with all types of indigenous roller bearings with world-class quality.

3>.OEM or Non-Stand Bearings:

Any requirement for Nonstandard roller bearings is Easily Fulfilled by us due to its vast knowledge and links in the industry.

4>.Genuine products With Excellent Quality:

The company has always proved the 100% quality products it provides with genuine intent.

5>. After Sales Service and Technical Assistance:

The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

6>.Quick Delivery:

The company provides just-in-time delivery with its streamlined supply chain.

7>.Cost Saving:

We provide long-life, shock-resistant, and high-reliability roller bearings with excellent quality and better performance.

Resulting in increased cost savings.

Q4: What will we do if you are not satisfied with the product?

A: If have any abnormal, Please contact us at the first time, we will immediately process

Q5: How long will you respond to our problems?

A: We will respond within 1 hour. 24 hours to solve your problem

Q6: Is optional lubrication provided?

A: We can offer a wide range of oils and greases for a variety of applications. Please contact our engineer for technical

assistance with any special requirements

Choosing a V-Belt

When choosing a v-belt, you should understand the characteristics of each type and how they affect the performance of your machine. Listed below are the characteristics of Cogged, Narrow profile, and wide v-belts. Learn about the advantages and disadvantages of each. Choose the right v-belt for your machine to maximize its performance. Learn about the different materials used to make v-belts and how they influence the performance of your machine.

Narrow v-belts

While the flat belts are the most common type of v-belt, narrow v-belts are also a common option for industrial applications. These belts are similar to wedge belts in that they transmit heavier loads, but in a smaller form. Narrow v-belts are typically designated as 3V, 5V, and 8V and are denoted by their top width, multiplied by an eighth of an inch. Narrow v-belt sections conform to a wedge belt profile and are usually standardized by manufacturers. For example, section 3V corresponds to a wedge-type profile, while section 5V corresponds to SPB.