Product Description

Wire Jump Preventer (NT002) Ceramic Caged Pulley for Wire Xihu (West Lake) Dis.

Anti jumper for winding to prevent jumper, the ceramic roller is made by ultra precision polishing made with high-speed bearing, make around line beats in a small range, maintained around the line tension stability.

Product Description

The caged ceramic pulley is applicable for wire jump prevention during winding. The middle ceramic roller is made by precise polishing and matched with high-speed bearings so that jumping during winding can be minimized to ensure tension stability.

| Place of Origin: | ZheJiang China |

| Brand Name: | KIMCHEN |

| Model: | Refer to the picture below |

| Material: | 99%AL2O3 |

| Function: | Prevent the wire jumping out |

| Polish: | Fine Polish degree Ra0.2 |

| Bearing: | High speeding bearing |

| Color: | Pink & Red |

| Screw Dia: | M2,M3,M4,M5 |

| Weight: | Refer to the picture below |

| Minimum Order Quantity: | 50 Pcs |

| Packaging Details: | Carton With Foam |

| Delivery Time: | 3 working days |

| Payment Terms: | T/T, Western Union, Money Gram, Paypal |

| Supply Ability: | 50,000pcs per month |

Relative Product Recommend

Company Profile

KIM CHEN INDUSTRY INTL LIMITED was founded in 2001, It is located in HangZhou City.

We specialize in the manufacture and RD of the component which is used in coil of wire and tension systems, textile machinery and electrical industry Precision Ceramics, automatic lathe products, precision machining manufacturing and water jet technology. Our company has more than 100 employees, of which nearly 20 technical staff.

With a strong technical force, professional processing equipment, we devote ourselves and development of the component which is used in coil of wire. We have accumulated rich processing experience in the Deep-processing of the super-hard alloy, Crystal Gem and Precision Ceramic. Our technology is improving day by day…We can be tailored to customer specifications of the various nozzles. Various products have been widely used in various types of electronics, machinery, textile and other equipment, its excellent performance and the reliable quality has fully met the international standards; One of the parts of precision grinding technology and quality standards even more than the international peer level.

After a few years development of the coil winding tension system and the production of the 2 series of 10multiple specifications tensioner, after the listing of products, we gain customer recognition with an annual output-5, 000 sets. At the same time we are exploring the development of new industrial categories, through the introduction of advanced international machine tool equipment, we have a certain production scale in the field of automatic lathe products, therefore we have the ability to undertake all types of non-standard nut (column), posts and large quantities of shaft processing with the stable and reliable product quality.

We manufacture only No Lead Green Products to protect our environment in order to fulfill our moral responsibility as a member of this earth.

We always adhere to quality first, technology first, service first, customer first to pragmatic, scientific management, innovation and integrity, excellence, management philosophy. The company not only selling products all over the country and exported to Southeast Asia, the Middle East, Europe and more than 20 countries and regions. In the companys leadership and staff of the joint efforts of the rapid development of the gold honesty CHINAMFG INDUSTRY INTL LIMITED. Sincerely hope to strong technical advantage, advanced management, quality performance and perfect after-sales service and work closely with customers home and abroad hand in hand, create brilliant future!

Continuous Development and Conscious Operation is our long term goal. We hope to develop properous collaboration with you in the future.

Certifications

Our Advantages

1:Nice Price with Nice Quality

2:Fast and best serive

3:Fast Delivery

4: Professional Experierence

5:Strong and Good package

FAQ

1.Q:Are you a factory or trading company?

A:We are a professional manufacturer.

2.Q:Where is your factory located?

A:Our factory is located in HangZhou, ZheJiang Province.

3.Q:How can I get a sample to test your quality?

A:The sample is available,for more detail, welcome to talk with us.

4.Q:How about your payment method?

A:TT,Paypal ,Online

5.Q:When can you deliver the goods?

A:If stock available, we can deliver it within 2 days. If not, that would be 5-7 working days after confirm the order.

6.Q:Does your company accept OEM or ODM production?

A:Yes, we are experienced in operating OEM & ODM, just send the detailed requirements.

7:Q: How about the delivery method?

Goods are usually shipped by air or sea via DHL,UPS,FEDEX,TNT. If you have a warehouse in China, we can also deliver the goods to your warehouse.

8:Q: What is your main product?

A: We are support one-stop winding parts,for more product, demand, welcome to send inquiry and contact us ,thank you .

Welcome to send inquiry to us, we will provide professional service and solution to you asap

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | on Line |

|---|---|

| Classification: | Special Parts |

| Processing Type: | Mechanical Process |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you explain the impact of tensioner rollers on the overall drivability of vehicles?

Tensioner rollers play a crucial role in the overall drivability of vehicles, particularly in systems that utilize belts for power transmission. The design and performance of tensioner rollers have several key impacts on the drivability of vehicles. Here’s a detailed explanation of their effects:

1. Reliable Power Transmission:

Tensioner rollers help maintain proper tension in the belts used for power transmission. By ensuring the right amount of tension, tensioner rollers prevent belt slippage, which is vital for reliable power transmission. Reliable power transmission improves the overall drivability of vehicles by ensuring smooth acceleration, consistent operation of accessories (such as the alternator, air conditioning compressor, and power steering pump), and optimal performance of the engine-driven components.

2. Minimized Belt Noise and Vibration:

Well-designed tensioner rollers contribute to reducing belt noise and vibration. Excessive belt noise and vibration can negatively impact the drivability of vehicles, causing discomfort to occupants and indicating potential issues with the belt system. Tensioner rollers with proper damping mechanisms and optimized design help minimize noise and vibration, enhancing the overall driving experience.

3. Enhanced Engine Efficiency:

Efficient power transmission is vital for optimizing engine performance and fuel efficiency. Tensioner rollers maintain proper tension in the belts, ensuring efficient power transfer from the engine to the driven components. By reducing belt slippage and maintaining optimal tension, tensioner rollers help maximize the efficiency of the engine, leading to improved fuel economy and overall drivability.

4. Prevented Belt System Failures:

Tensioner rollers play a critical role in preventing belt system failures. They help extend the lifespan of belts by reducing wear and preventing excessive stress or strain on the belts. By maintaining proper tension and alignment, tensioner rollers minimize the risk of belt damage, premature wear, or sudden belt failure. Preventing belt system failures ensures uninterrupted power transmission, preventing drivability issues and potential breakdowns.

5. Reduced Maintenance Requirements:

Properly functioning tensioner rollers can reduce the maintenance requirements of the belt system. By maintaining optimal tension and alignment, tensioner rollers help minimize wear and prolong the lifespan of belts and other components. This reduces the frequency of belt replacements, adjustments, and related maintenance tasks, contributing to improved drivability by reducing downtime and maintenance costs.

6. Improved Belt System Durability:

Tensioner rollers with robust design and high-quality materials enhance the durability of the belt system. They withstand the demands of the operating conditions, such as temperature variations, engine vibrations, and belt loads. Improved durability of the belt system ensures long-lasting performance, minimizing the risk of unexpected failures or drivability issues due to worn-out or damaged belts.

7. Compliance with Manufacturer Specifications:

Tensioner rollers that meet the manufacturer’s specifications and recommendations contribute to optimal drivability. Automotive manufacturers often design and specify tensioner rollers that are compatible with their specific engine and accessory systems. Using tensioner rollers that comply with these specifications ensures proper fitment, operation, and performance, promoting optimal drivability of vehicles.

In summary, tensioner rollers have a significant impact on the overall drivability of vehicles. They ensure reliable power transmission, minimize belt noise and vibration, enhance engine efficiency, prevent belt system failures, reduce maintenance requirements, improve belt system durability, and comply with manufacturer specifications. Investing in high-quality tensioner rollers and ensuring their proper functioning can greatly enhance the drivability, performance, and reliability of vehicles.

How do tensioner rollers contribute to reducing wear and increasing the lifespan of belts?

Tensioner rollers play a vital role in reducing wear and increasing the lifespan of belts in various applications. They offer several key contributions in achieving these objectives:

1. Maintaining Proper Belt Tension:

Tensioner rollers help maintain the optimal tension in belts throughout their operation. Proper tension is crucial for efficient power transmission and preventing belt slippage. When belts operate under inadequate tension, slippage can occur, leading to increased wear on the belt and associated components. Tensioner rollers ensure that the belts remain appropriately tensioned, reducing wear and extending their lifespan.

2. Absorbing Belt Vibrations:

Vibrations can occur in belt drive systems due to imbalances, misalignments, or variations in load. These vibrations can accelerate belt wear by causing friction and excessive flexing. Tensioner rollers are designed to absorb and dampen vibrations, minimizing their impact on the belt. By reducing vibrations, tensioner rollers help to decrease wear and prolong the life of the belt.

3. Distributing Tension Evenly:

Tensioner rollers distribute tension more evenly along the length of the belt. They help prevent localized areas of excessive tension, which can lead to premature wear and belt failure. By ensuring a more uniform distribution of tension, tensioner rollers contribute to reducing wear and extending the lifespan of belts.

4. Compensating for Belt Stretch:

Over time, belts can stretch due to the mechanical stresses they experience during operation. Belt stretch can result in reduced tension and compromised power transmission. Tensioner rollers are designed to compensate for belt stretch by applying additional tension to maintain the desired level of belt tension. This compensation helps to prevent belt slippage, wear, and premature failure, thereby increasing the lifespan of the belt.

5. Reducing Belt Misalignment:

Proper belt alignment is essential for minimizing wear and optimizing belt life. Tensioner rollers assist in maintaining belt alignment by exerting consistent pressure on the belt and guiding it along the desired path. By reducing belt misalignment, tensioner rollers help prevent edge wear, side-loading, and premature belt failure.

6. Providing Belt Support:

Tensioner rollers provide support to the belt, especially in longer spans or applications with heavy loads. They help prevent belt sagging and excessive flexing, which can lead to accelerated wear and reduced belt life. By offering support, tensioner rollers contribute to minimizing wear and increasing the durability of the belt.

7. Facilitating Belt Tracking:

Proper belt tracking is crucial for belt longevity and performance. Tensioner rollers aid in maintaining belt tracking by applying controlled pressure and guiding the belt along the intended path. By promoting accurate belt tracking, tensioner rollers help prevent edge wear, rubbing, and premature belt failure.

8. Minimizing Belt Slippage:

Belt slippage can occur when there is insufficient tension or excessive loads in the system. Tensioner rollers help maintain the necessary tension in the belt, ensuring a secure grip between the belt and the pulleys. By minimizing belt slippage, tensioner rollers reduce wear, heat generation, and premature belt failure.

In summary, tensioner rollers contribute significantly to reducing wear and increasing the lifespan of belts by maintaining proper tension, absorbing vibrations, distributing tension evenly, compensating for belt stretch, reducing belt misalignment, providing belt support, facilitating belt tracking, and minimizing belt slippage. These contributions help optimize the performance, efficiency, and longevity of belt drive systems in various applications.

How do tensioner rollers differ from other components in a vehicle’s belt drive system?

Tensioner rollers in a vehicle’s belt drive system have distinct characteristics that set them apart from other components. Here’s a detailed explanation of how tensioner rollers differ from other components in a vehicle’s belt drive system:

1. Function:

Tensioner rollers are specifically designed to maintain proper tension in belts within the vehicle’s belt drive system. Their primary function is to apply the necessary force to keep the belts properly tensioned, ensuring efficient power transmission and preventing slippage. Other components in the belt drive system, such as pulleys or idler pulleys, have different functions like redirecting the belt’s path or guiding it around various engine accessories.

2. Design:

Tensioner rollers, also known as belt tensioners or idler pulleys, typically consist of a pulley-like structure mounted on a spring-loaded arm or bracket. They have a smooth or grooved surface that comes into contact with the belt. The design allows the tensioner roller to rotate freely on bearings or bushings, accommodating the movement of the belt and maintaining the desired tension. In contrast, other components in the belt drive system, such as crankshaft pulleys or accessory pulleys, have different shapes and configurations depending on their specific tasks.

3. Tension Adjustment:

Tensioner rollers are designed to automatically adjust the tension in the belts. They can compensate for belt stretch or wear by adapting their position and maintaining the desired tension level. This self-adjusting feature ensures consistent belt tension throughout the vehicle’s operation. In contrast, other components in the belt drive system usually have a fixed position and do not actively contribute to tension adjustment.

4. Location:

Tensioner rollers are typically positioned at strategic locations within the belt drive system to optimize tensioning. They are often placed in locations where the belt’s tension tends to decrease due to the movement of different engine accessories. This placement allows the tensioner rollers to provide the necessary tension and prevent belt slippage. Other components, such as crankshaft pulleys or accessory pulleys, have specific positions based on their roles in driving the various engine accessories.

5. Maintenance and Replacement:

Tensioner rollers require regular maintenance and inspection to ensure their proper functioning. They may need lubrication, and their condition should be checked for signs of wear, damage, or misalignment. If a tensioner roller is found to be faulty or no longer providing adequate tension, it should be promptly replaced to prevent belt-related issues. Other components in the belt drive system may have their maintenance requirements and replacement intervals based on their specific design and usage.

6. Impact on Belt Performance:

Tensioner rollers have a direct impact on belt performance by maintaining the correct tension. They help prevent belt slippage, ensure optimal power transmission, and contribute to the overall efficiency and reliability of the belt drive system. Other components, although crucial for the system’s operation, may not have the same direct influence on belt tension and performance.

In summary, tensioner rollers differ from other components in a vehicle’s belt drive system in terms of their function, design, tension adjustment capabilities, location, maintenance requirements, and impact on belt performance. Understanding these differences is important for effectively maintaining and optimizing the performance of the belt drive system in a vehicle.

editor by Dream 2024-04-24

China Standard Alumina Al2O3 Textile Ceramics Parts for Loom Machine with Great quality

Product Description

textile ceramics parts

Textile ceramics are mainly produced from alumina ceramic materials, which have excellent comprehensive technical properties such as high mechanical strength, high hardness, low high-frequency dielectric loss, high temperature insulation resistance, chemical resistance and good thermal conductivity.

Material option:

Steatite

Alumina up to 99.7 % or 95% alumina

Titania

Zirconia

Range of products:

Flange Eyelet, Double flange eyelet, Slotted eyelet, groove eyelets, step eyelet, Cut Eyelet, Step Eyelets, Tubes, Rods, Sleeve,

Ring, Bush, Disc, Dish, Washer, Plates Trap Xihu (West Lake) Dis., Traverse Xihu (West Lake) Dis., Pig tail Xihu (West Lake) Dis., Dog tail Xihu (West Lake) Dis., Rollers, Oilers, Oiling Nozzles Cutters

Application :

Yarn manufacturing machines

Twister machines

Airjet looms

Circular looms

weaving machines

winder machines

Rope,Tap plants

Customized guides as per detailed drawings and specifications.

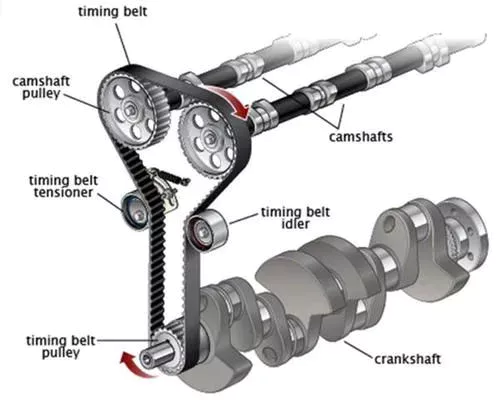

The Advantages and Disadvantages of Neoprene Timing Belts

The timing belt is an important component of an automobile engine. Made of special materials, this belt coordinates the rotational motion of the crankshaft with the camshaft. The coordinated precision is essential for sustainable combustion, and ensures that the valves in the combustion chamber open at the right times. Timing belts determine the engine’s pace, so it is essential that they perform at high synchronicity and strong enough to operate in extreme conditions.

Fabric timing belt

A timing belt is made of a yarn that has been crimped and woven into a mating surface, called the engagement surface. This yarn, known as the warp, must be able to stretch from a substantially flat state along irregularities in the mold. It must be flexible enough to stretch by several tens of percent under low load conditions. The warp yarn of a timing belt is made of synthetic fiber and is crimped into the right shape to be stretched easily.

This fabric can be used without thickening the base cloth. It can contain a large number of warp threads, and its wear resistance can be enhanced over time. The timing belt of the present invention does not crack or wear out after a long time of use. The base cloth does not wear out, which allows the timing belt to last for a long time. This makes it an extremely durable material. To learn more, read on.

The teeth of a timing belt are made of tough rubber and a nylon fabric facing. The fabric is coated with a plastic compound that gives it its shape and covers the cord. The materials used to make these belts vary, but all are strong and durable. They are also suitable for high-load applications. In addition to nylon timing belts, strongbelt premiums are also available. In addition to nylon and neoprene timing belts, they are also compatible with RPP and HTD pulleys.

The teeth of timing belts are made of high-strength polychloroprene elastomer. The teeth are made of a special manufacturing process that ensures good adhesion. The facing fabric is made of low-elongation glass cord and is covered by a polyamide fabric that has a low coefficient of friction. If you need an exact fit, you can buy a high-quality belt from TransDev.

Neoprene timing belt

When it comes to dependable drive belts, neoprene is hard to beat. It’s widely used in insulated clothing and weather stripping, and has been a key component in the development of timing belts since the late 1970s. And because it’s so hardy, neoprene timing belts are incredibly reliable. Here are a few reasons why. Neoprene is the most durable synthetic material for timing belts, and these 3 reasons should not discourage you from purchasing a new neoprene timing belt.

Neoprene timing belts are made of a high-quality chloroprene compound with a hardness of 74 Shore A. The high-strength glass fiber strands in the belt’s body transmit high power while enhancing its flexural strength. In addition, it’s covered with a high-strength polyamide fabric to reduce friction and protect contact surfaces from wear and tear.

Unlike neoprene, polyurethane synchronous belts are resistant to temperature and abrasion. Polyurethane timing belts are resistant to acids and chlorides, and exhibit excellent abrasion resistance. A neoprene belt can be used in high-speed applications, and can withstand extreme temperatures. However, the resistance of polyurethane to abrasion is not as good as that of neoprene.

The 2 most common types of timing belts are rubber and urethane. Rubber is the least expensive and quietest, and is the least flexible of the two. Neoprene is also highly elastic and does not retain its shape when it’s stretched, making it a popular choice for applications in manufacturing, agriculture, and robotics. They are also great for applications where precision and motion control are important. These properties make timing belts extremely effective in leading the industry toward its goals.

Chain timing belt

Traditionally, a vehicle’s timing system consists of a timing belt or chain. These components keep the engine’s intake and exhaust valves in the proper order. When these components go bad, it can ruin the engine in seconds. But there are advantages and disadvantages to each of them. Read on to learn about the pros and cons of each type of timing system. Here are some examples. Chain: A timing belt is generally made of reinforced rubber.

Chain: A timing chain is generally found in heavy-duty vehicles with higher torque. This type of timing belt is also found on many cars and SUVs with 4 cylinder engines that do not require a lot of torque. Unlike timing belts, timing chains are more durable and will last longer than their rubber counterparts. But there are certain things to keep in mind when replacing a timing belt. Make sure to change the oil regularly to avoid premature wear.

Chain: A chain is easier to maintain than a timing belt. It does not change length in response to temperature. And it requires a smaller tensioner. However, this also means that the timing belt is more prone to breaking. It can jump out of place if oil is flowing along it, causing an engine malfunction. If this happens, you’ll have to replace the entire timing belt and the engine will not work correctly. That’s why replacing a chain is so important.

A timing belt is a critical part of an engine. A failed timing belt can cause catastrophic engine damage. It can slip and break, colliding with the piston and valves. Fortunately, there are a variety of ways to check your timing belt. But a good rule of thumb is to replace it as soon as possible. You’ll also need to remove the front engine cover and any other components that may be in the way. In some cases, the engine might even have to be moved.

Trapezoid shaped teeth

In terms of tooth profile, there are 2 main types of timing belts: the curvilinear and trapezoidal types. Curvilinear timing belts are more rounded and less likely to result in excessive tension loss. These types of timing belts are also more prone to backlash and reduce accuracy. Here’s how they differ from each other. These 2 types of belts share similarities but differ in important ways.

Older timing belts generally have trapezoidal-shaped teeth, but newer types use curved teeth. Curved teeth are less prone to wear out quickly and last longer than straight ones. The trapezoidal teeth also tend to wear out more quickly at higher speeds. As a result, they’re only suitable for cars that get very little use. If you’re planning on using your timing belt frequently, you may want to choose a new 1 with curved teeth.

Curvilinear teeth are designed to alleviate the stress concentrations caused by trapezoidal tooth profiles. They also have a greater depth and reduce ratcheting. In addition to their efficiency, curvilinear timing belts are quieter than their trapezoidal counterparts. And they’re a little bit more expensive than their trapezoidal counterparts. So, what’s the difference between these 2 types of teeth?

Timing belts have a tendency to favor the tracking of an “S”-shaped twist. As a result, a trapezoid-shaped timing belt is more likely to keep the engine in sync. A good quality timing belt will help you achieve this. If you don’t, consider replacing your timing belt with a metric-styled one. That way, you’ll get the best performance out of your belt.

Other types of timing belts

Timing belts are essential for operating your vehicle’s engine. These belts connect the engine’s crankshaft and camshaft. The belts synchronize the timing of the engine’s valves and pistons to prevent damage. Previously, the belt was referred to as the “gilmer drive belt.”

There are 3 basic designs for timing belts. Some are shaped like a trapezoid, while others have a curvy tooth shape. Timing belts with this tooth design are generally more efficient for force transmission, although they suffer from backlash. These teeth also wear quickly at high speeds, which can make them prone to noise. In order to solve these issues, manufacturers now offer belts with curved teeth.

Another popular type is polyurethane. These are resistant to oil and high temperatures, and are energy-efficient solutions. Polyurethane timing belts offer increased elasticity and load capacity, which are important for optimal torque production. These belts are favored by a variety of industries because of their ease of cleaning and maintenance. They can be used for power transmission systems, as well as in roller conveyor systems. However, fabric timing belts are best used when acceleration forces are high.

Other types of timing belts are not always as durable. V-Belts have teeth-like structures on their surfaces and work under constant speed. They are typically a lighter option, but have similar disadvantages. They are more expensive than chains and lack the flexibility of customizing. Unlike chains, timing belts are sold in predetermined length loops. Their pitch is easily identified. It is a key indicator of whether or not they are suitable for a specific application.

China Good quality Textile Machine Manufacture Coil Winding Parts High Performance Ceramic Wire CZPT Pulley with Great quality

Product Description

Textile Machine Manufacture Coil Winding Parts High Performance Ceramic Wire Xihu (West Lake) Dis. pulley

Product Description:

1. In the wire and cable industry, ceramics has become the material of choice and convenience. Almost all facets of wire and cable manufacture have benefited by the use of ceramics in the production processes.

2. Product quality and output have been maximized with minimum downtime; Lower wear

Problems and surface defects.

3. Pulley flanges, CNC Machined and available in fully anodized Aluminum, coated with anti corrosion layers, are not affected by most wire drawing solutions and do not need frequent maintenance vis-à -vis Phenolic materials. The flanges are held together by means of SS screws. High performance bearings are used and are pressed fitted into the metal flanges. The metal part is duly anodized to prevent rusting.

Product Feature:

1. Flanged ceramic roller, Wire CZPT pulleys (ceramic pulleys) is commonly used component when wire passing is required, it can be used in coil winding machine, cable machine and the textile machinery as well. The porcelain ring is mounted on the bearing, Coil winding wire CZPT pulley(wire roller) will rotate by the thread and wire passing on the surface of the ring. Thus the sliding friction has been converted to the static friction.

2. But at the start and stop, in order to overcome the inertia, there will be a partial sliding friction. The surface Polish degree of the porcelain ring reaches Ra0.2; The beating during rotation is under 0.15. We select the 99% AL2O3 as the material with the hardness of HRA88 and the density of 3.85…Two nylon side walls have been put to the both side of the ceramic ring and the bearing, coil winding wire CZPT pulley (wire roller) combines 1 wire roller.

Service:

1. With many available designs and configurations, such as bolt together, solid ceramic, or coated aluminum. CZPT can satisfy the unique requirements of the wire and cable industry.

2. HARTAI’s AL95 CZPT pulleys are long lasting, will help improve wire surface quality and at the same time reduce maintenance and production costs.

3. CZPT offers dozens standard sizes of CZPT pulleys. A large inventory of pulleys is maintained for the most widely used sizes for immediate delivery. Xihu (West Lake) Dis. pulleys can also be manufactured to specific requirements and detail.

Feature of our ceramic wire CZPT small pulley

1.The middle ceramic coil is made of precise ceramic and matched with high-speed bearing .

2. The winding tension can be maintained in a stable manner through the pulleys .

3.Baffles in both sides can prevent the wire to jump out of the groove .

4.The groove is polished to Ra0.2 .

Advantage of this ceramic wire CZPT small pulley

1.Easy to be installed

2.Low coefficient of friction

3. High speed running bearing

4.High quality and competitive prices

Specifications of ceramic wire CZPT small pulley

| Modle No. | A(mm) | B(mm) | C(mm) | D(mm) |

| HT001 | 7.8 | 6 | 2 | 3.2 |

| HT002 | 8 | 8 | 2 | 4 |

| HT003 | 10.6 | 7.3 | 2 | 3.5 |

| HT004 | 12 | 10 | 4 | 4 |

| HT005 | 14 | 10 | 3 | 6 |

| HT005-C04 | 21.5 | 14 | 4 | 10 |

| HT005-C05 | 21.5 | 14 | 5 | 10 |

| HT006-C05 | 30 | 24 | 5 | 11 |

| HT006-C06 | 30 | 24 | 6 | 11 |

| HT006-C07 | 30 | 24 | 7 | 11 |

| HT006-C08 | 30 | 24 | 8 | 11 |

| HT007-C05 | 35 | 24 | 5 | 11 |

| HT007-C06 | 35 | 24 | 6 | 11 |

| HT007-C07 | 35 | 24 | 7 | 11 |

| HT007-C08 | 35 | 24 | 8 | 11 |

| HT008-C05 | 40 | 24 | 5 | 12 |

| HT008-C06 | 40 | 24 | 6 | 12 |

| HT008-C07 | 40 | 24 | 7 | 12 |

| HT008-C08 | 40 | 24 | 8 | 12 |

| HT009-C09 | 45 | 36 | 9 | 13.5 |

| HT009-C10 | 45 | 36 | 10 | 13.5 |

Display of the ceramic wire CZPT small pulley

Information of our company

HARTAI Technology Industry Co., Ltd , found in 2001, is located in the beautiful city of China’s manufacturing industry HangZhou City. It is committed to nozzle, ruby products, tungsten carbide products, ceramic products, plastic crochet hook and precision machinery manufacturing .Our main products are nozzle, ceramic roller, jump wire preventer, various sizes of ceramic eyes, combination wire roller, ceramic wheel and non-standard parts, all kinds of tension and so on.

FAQ

1. How can I get a quotation?

You can find our contact information below this page and some detail information will be very helpful to get an exact quotation. We will give quotation within 24hours, if urgent, please tell us and we will regard your inquiry priority.

2. How can I get a sample?

As the price confirmed, you can require for samples.

3. Can you do the design for us?

Yes, we have our factory and we can make OEM order.

4. How long can I expect to get the sample?

Normally it takes 7-15days to produce the sample.

5. What about the lead time for mass production?

It depends on what kind of products you ordered. Generally, 15-25days for mass order.

We sincerely hope to get your inquiry of this voice coil actuator! If any questions, please feel free to contact us. Thanks for visiting our website!O(∩_∩)O

What to Look for in a Belt Tensioner

If you notice the power steering, air conditioning, or power steering stops working, chances are that your belt tensioner has been compromised. A compromised belt tensioner can be completely destroyed overnight, or it can last for a long time before it breaks. Either way, you should never drive with a faulty belt tensioner. It’s far better to have it replaced before the engine shuts down completely. In addition, replacing a belt tensioner will prevent other complications, such as power steering or air conditioning, from occurring.

Misaligned idler pulley

If the tensioner arm is not rotating freely or has an abnormal chirping noise, it could be the result of a misaligned idler pulley. If this is the case, replace the idler. If the idler does not move, you may need to adjust the accessory mount points or use a laser alignment tool. The tensioner arm is only 1 part of the tensioner.

A misaligned idler pulley on a belt tensioner is usually the cause of a squeaking noise. If this noise continues even after a replacement of the belt, it’s time to replace the whole belt. A misaligned idler pulley can also be the cause of premature belt wear. If the idler pulley is out of alignment, it could also cause the belt to wear too fast and lead to the premature failure of the timing belt.

The tensioner pulley is made of nylon, steel, or plastic. It may be flat or grooved. Before replacing it, check for any cracks, dents, or debris on the pulley’s surface. Plastic pulleys may have broken sidewalls. If the idler pulley is worn out, you might also notice squealing noises when the vehicle is in motion.

The misalignment of a belt is most pronounced when the span between the 2 pulleys is short. When the span is long, however, diagnosing the problem becomes more complicated. Small degrees of offset may not be visible to the naked eye, but a laser alignment tool can help identify these subtle variations. In order to identify a misaligned idler pulley on a belt tensioner, you must first determine its cause.

When the tensioner’s idler pulleys are out of line, a belt tensioner will not be able to properly adjust the torque that the belt is under. This may result in squealing noises. If this is the case, it is time to call a mechanic. He or she will be able to determine the cause and correct it. If you suspect the problem, your next step is to replace the idler pulley on the belt tensioner.

If the ribbed belt is not properly aligned, you may have a misaligned idler pulley. To fix the misalignment, locate the belt adjustment bolt underneath the hood. You should be careful not to damage the alternator or battery terminal while doing this task. If you do accidentally connect the battery positive to the earth, you might be able to damage the ribbed belt and ruin your vehicle’s timing.

Besides a misaligned idler pulley on the belt tensioner, another problem may be the alternator’s serpentine belt. If your car’s alternator belt is not aligned properly, you could have misaligned the alternator’s pulley or a worn-out bearing. Regardless of the cause of your problem, you should have the belt inspected.

Bad idler pulley

Having a Bad Idler Pulley on a Belt Tensioner? If this sounds familiar, then it’s probably time to change it. Idler pulleys slowly take hits while the engine is running, causing the belt to wrap and bend. Eventually, the belt will slip, and a new idler pulley should be installed to ensure optimal tension. But before you spend a dime on a new one, let’s talk about what to look for.

Symptoms of a Bad Idler Pulley: If the noise persists, there is a problem with the idler pulley or its bearing. These parts wear out over time and may eventually cause a cracked idler pulley or serpentine belt. Not only will the idler pulley create an irritating noise, but it will also damage the belt itself, leading to overheating, stalled engine, and even damage the head gaskets. Thankfully, a Bad Idler Pulley on a Belt Tensioner is easily replaced and will only cost about $40.

Although the Idler Pulley is not the most popular component on a car, it’s a critical part that ensures that the engine runs smoothly. It’s easy to overlook this part, but its failure can make it impossible for your vehicle to operate at its optimal level. Moreover, a Bad Idler Pulley on a Belt Tensioner will cause your engine to malfunction, so it’s essential that you check it at regular intervals.

If you notice a squealing noise while driving, the Idler Pulley is likely the culprit. Because of friction between the engine belt and idler pulley, the engine belt rubs against the pulley, causing it to squeak and make a clicking noise. This squealing noise will continue until the problem is repaired or replaced. It’s time to start addressing the problem before it becomes too late.

If you notice the tensioner pulley moving away from the engine, it’s most likely that the pulley is malfunctioning. A belt that is loose or slack may make it difficult to start the car, or your engine may even overheat. If this occurs, it’s crucial to replace the Idler Pulley as soon as possible, because a Bad Idler Pulley on a Belt Tensioner can seriously damage your vehicle.

The Idler Pulley facilitates the motion of the engine belt. It serves as a smooth rotating point that allows the belt to loop without a barrier. Over time, this part of the system will begin to show signs of wear and tear, and replacement is vital to protect your engine, serpentine belt, and other accessories. An early warning sign of a problem is a squealing sound coming from the engine area.

Broken tensioner arm

The belt tensioner is a piece of machinery that is used to keep the belt tight. If this part breaks, you can easily repair it yourself using a long-handled ratchet, serpentine belt tool, or a socket. To repair the tensioner, simply remove the drive belt from the pulley and rotate it to release tension. Check for roughness, resistance, or binding of the drive belt.

Noises caused by the tensioner are a sign of a damaged component or excessive oscillation. These noises are usually caused by worn internal components or the tensioner’s pivot bushing. In some cases, the vibration damping system or a worn-out alternator pulley could also be to blame. If this is the case, replace the pulley and tensioner together. To check the condition of your belt tensioner, follow these steps.

In addition to worn-out springs, a loose or broken pivot arm could be causing your belt to misalign. A worn-out tensioner pulley bushing will also cause vibrations, noise, and seizing. Lastly, a broken tensioner spring could be preventing the belt from maintaining proper tension. Broken springs are also prone to loss of tension due to heat. Damaged tensioner housing can also affect belt tension.

Once the belt is installed, you need to check the condition of the pulley and the tensioner arm. Make sure that the pulley is moving and that the arm is moving smoothly with the cranking and releasing. If the arm is wobbling, the tensioner is failing. If the pulley wobbles or excessive chattering occurs, the tensioner is failing. It can also be seized or jammed.

If the tensioner arm has broken, replace it. Replacing the tensioner can be a tedious task. Be sure to use a suitable tool to tighten the pulley and tensioner. If you are not sure of how to replace the pulley, try using a serp belt tool. Another good option is to purchase a 3/8 drive ratchet. If you don’t have this tool, you can use a long 3/8 extension and a deep socket.

The belt tensioner assembly can fall off the engine, causing damage to the timing belt. If you are replacing it, you must replace it with a new one, and tighten all of the mounting bolts before reinstalling it. To avoid further damage to the engine, ensure you replace the belt with a new tensioner and a new belt. The tensioner is bolted to the engine’s timing cover, so make sure you carefully tighten the bolts when replacing it.